2020 was a year we'll all never forget. As all of us moved to more digital work and meetings, there was definitely a learning curve. In the churn, did something slip by?

During the year, DCS produced three webinar series and released new optimizers and techniques to help you do more, faster. DCS worked hand-in-hand with Daimler to complete a validation on FEA Compliant Modeler and participated in a number of industry events that have all gone digital. Did you miss any of these? If so, scroll down to catch up before 2021 begins in earnest!

In 2020 DCS looked at how Model Based Definition intersected Product Lifecycle Management PLM, beginning with Design and moving the model through the phases of PLM utilizing Model Based Definition.

Design -- Engineering Specs & Simulation -- Measurement Plan & Sharing -- Supplier Quality

The first part of the series began with:

Optimizing early GD&T is important to MBD, as GD&T is the core instructions used throughout the entire process to describe the manufacturing process and quality objectives being sought. This webinar showed how to utilize built-in tools to help write GD&T in your CAD, and then leverage 3DCS as an integrated tool to validate and optimize the GD&T for manufacture and assembly (DFMA).

After setting tolerance objectives, the design team wants to see how they will affect the product's appearance. In addition, the two teams, Design and Manufacturing Engineering, need to compare notes on acceptable tolerance limits. Design determines their tolerance specifications from Perceived Quality Studies, called Spec Studies in 3DCS, to see what acceptable Gap and Flush conditions are that will still keep the product's appearance at the level the team finds acceptable. For high end products, especially in automobiles, this means extremely small gaps, and little to no flush, while lower end models may have gaps but need to still cover internal components.

The third part of the series brought up advanced studies that Manufacturing Engineering oftentimes uses to validate design specifications. This study demonstrated the improvement when applying FEA Compliant Modeler to mechanical kinematic models, both in added complexity and deeper understanding, that can provide a more realistic behavior for your model.

QDM allows downstream users to take advantage of MBD. By providing measurement plans and quality reports based on and correlated to your CAD model, you can connect the Digital Thread, leveraging the assets you have spent so much work on. This release compiled all of the updates, enhancements, and new features added over the last 12 months to make it easy to utilize in your quality reporting and SPC studies.

Bringing your supply chain onboard with MBD can be difficult. By providing controlled access to your quality data and measurement plans developed from your MBD Model, suppliers can be connected to the Digital Twin and take advantage of the benefits of MBD, even if they don't realize it!

Learn how to incorporate your suppliers into your quality enterprise and provide the benefits of MBD to your supply chain.

In April, DCS released 3DCS Version 7.7.0.0. This major release of 3DCS [see current release updates here] brought a lot of new updates and tools:

There were so many new additions to 3DCS that we had to put out a minor release too! These quality of life improvements and new optimization tools make it easier to complete your model, and start getting answers that you need to make important decisions on your manufacturing quality.

MBD only works if the organization adopts it. It becomes imperative then to establish the value of dimensional engineering on the rest of the organization. Dimensional Engineer Ulrich Decker demonstrated how to convey the value of Dimensional Engineering to the other teams at your organization by answering the following questions:

In MBD, it is often necessary to utilize the CAD data in many different applications. Naturally, the less you have to move the data between platforms the better, but in our current day and age this is just a necessary activity. TransMagic CAD translation software automates the complex and time-consuming processes of moving data between systems so users can get more work done.

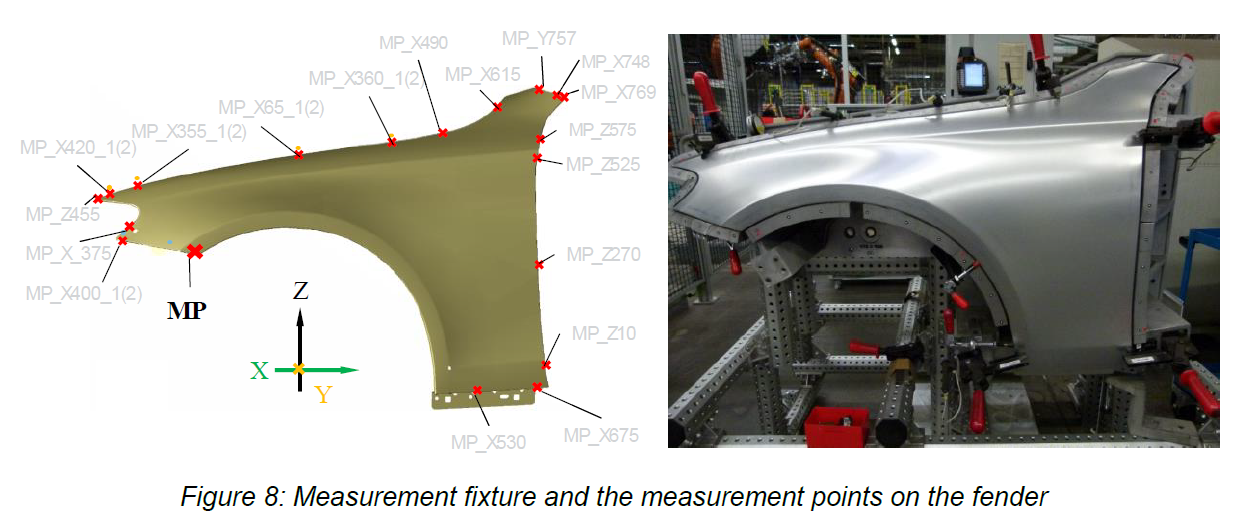

To show how MBD functions in the real world, Zheng described a comparative study of a front fender measured in the plant and simulated with 3DCS FEA Compliant Modeler to determine how close to reality the simulation came. The goal is to reduce prototypes by creating Digital Twins, digital prototypes in CAD that respond like real parts.

Reduce lead and launch time by eliminating or minimizing manual join & clamp sequence studies by determining the optimal join and clamp sequence from a candidate set.

The NEW 3DCS Datum Optimizer is a tool using a genetic algorithm to determine the optimal datum features from a candidate set with the goal of minimizing the rigid part variation or compliant part deformation.

DCS produced three exciting Whitepapers, with a fourth on the way!

2 Whitepapers, exclusively provided to Webinar registrants, will be available this year starting next month:

MBD only provides value if you have a model that can be leveraged for quality studies, and provide answers to quality issues. Gears have traditional been difficult to accurately model in any CAD system, but now 3DCS can assess gear backlash and mounting misalignments, perform angular backlash analysis, and create flank test displays and contact patterns. Here are some of the measurements it supports:

-- Backlash and system backlash.

-- Line of action contact.

-- Center mounting distance.

-- Mounting angles.

-- Contact pressure angles.

-- Flank contact area.

-- Radial tooth interface.

-- Radial tooth gap.

Implementing MBD with Digital GD&T, a Hybrid Approach

Why Simulating Manufacturing Process is Pivotal to Quality

GD&T Training Goes Digital with New Trainer at DCS

Why Adopt GD&T as a Work Method

Why Be Afraid of Profile GD&T - Advice from an ASME GD&T Trainer

Tolerance Simulation Software Makes Broader Use of Simulation Tools a Reality

Read More Articles from the DCS Blog

IMTS SPARK - The Digital Version of the Enormous IMTS EVENT

ASQ Quality Summit - Leveraging SPC for Small and Medium Companies

Dassault Modeling and Simulation Conference

3DEXPERIENCE WORLD - the new SOLIDWORKS WORLD

These Stories on CATIA

No Comments Yet

Let us know what you think