Article written and provided by DCS partner Gili Omri, TES-Rnd

GD&T has the potential to provide incredible improvements in efficiency, communication, and quality but come at the cost of training, implementation, and cultural adoption

Learn more about GD&T Here - What is GD&T?

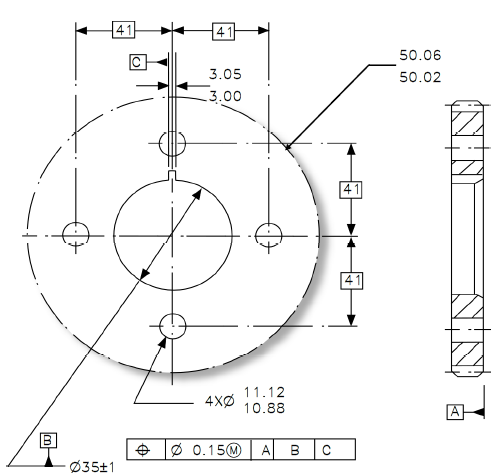

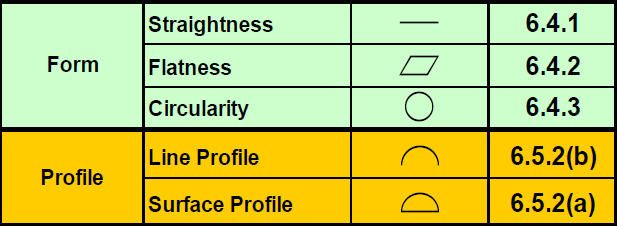

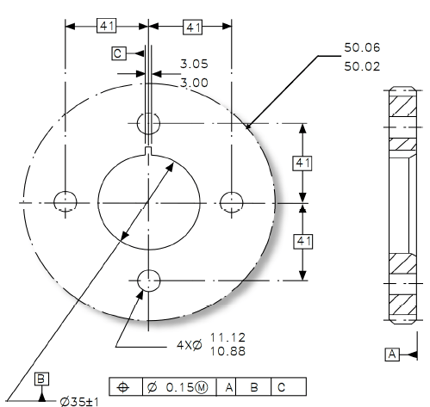

GD&T (Geometric Dimensioning and Tolerancing) is an international, concise and precise symbolic language developed for the express purpose of documenting Design Intent, to detail the functional requirements of a manufactured assembly part and to ensure the compatibility and interchangeability of those parts.

GD&T provides the links between theoretical 3D models, CAD (Computer GD&T is the tool for precisely and clearly defining functional specifications for size, form, orientation Aided Design), CAM (Computer Aided Manufacturing) and CAI ((Computer Aided Inspection) and the real world; and location of the elements of a manufactured part.

Globalization and the expansion of outsourcing increases the awareness that GD&T is essential. Products developed in one country are manufactured in other countries around the world and assembled in still other countries. This increases the need of a common language. GD&T provides for the intercommunication between organizations, cultures and continents.

GD&T is based on standards, which play a critical role in draftsmanship and reading technical drawings. The standards define a set of symbols, definitions, rules and conventions. Without these standards, detailed annotations would be required in order ensure the precise definition of production requirements and control for each manufactured part.

ASME and ISO are industries’ most widely used standards. There are also local standards, most of which are based on the ASME and ISO standards. As of the 1990s, there has been a large investment in reducing the gaps between these two standards. However, differences still exist in the symbols and in certain rules of the two standards.

There are no agencies to enforce the GD&T standards, but since draftsmanship is a key element in landing an order (of legal contract character), the absence of a standard or a reference to a standard to be used to interpret the drawing leaves room for interpretive disagreements of the drawing document. Thus, the selection and integration of a standard at the organizational level is of paramount importance.

Unfortunately, GD&T is not taught in most vocational training institutions in a comprehensive manner, but only as a subparagraph in draftsmanship courses or computerized drafting courses.

The periodical upgrades in the international standards (for example, the 2009 revision of the ASME 14.5 standard) reflect industry need and technological advances; the training program provide up-to-date knowledge and its efficient utilization.

The best to place to start is to discuss implementation with an expert. DCS and TES-RnD have ASME certified trainers who can discuss implementation, adoption, best practices, and provide training courses to get your people up to speed.

Gili Omri, Founder & CTO at TES-RnD - https://www.tes-rnd.com/en/

https://www.linkedin.com/in/giliomri/

Expert in GD&T, holder of ASME (American Society of Mechanical Engineering) certification at its highest level, Senior GDTP -S.

Delegate of Israel in the ISO committee that deals with the GPS standard (specifications and validation).

Technical expert in the ISO TC213/WG18 GD&T working group. Mechanical engineer with years of real-world Mechanical R&D experience.

I provide GD&T training and consulting to companies in wide array of fields such as Aerospace, Defense, Medical devises, Semiconductors, etc…

GD&T (ASME) and GPS (ISO) training and consulting focus on functional constraints and the interdependent relationship between design, production and quality. The training has proven its effectiveness and is delivered to small, medium, large international companies.

Promoting Variation Analysis software to mitigate non-compliance, assembly issues, and similar risks as well as product and process optimization upfront.

Expert in utilizing light-weight material (composite materials, magnesium) solutions, and design optimization.

These Stories on CATIA

No Comments Yet

Let us know what you think