Unveiling the latest enhancements in 3DCS Version 8.2, advancing variation analysis in the manufacturing industry.

Click Here to Download the What's New Document

Looking to Download the New Software? Request it Here!

DCS, part of Sandvik Group, is proud to announce the release of 3DCS Variation Analyst Version 8.2. This new version comes packed with a host of enhancements and features that push the boundaries of tolerance and variation analysis within the manufacturing industry. Whether you are in automotive, aerospace, or high-tech electronics, 3DCS 8.2 offers advanced tools to streamline your design and production processes.

This update incorporates user feedback and addresses various issues, ensuring more reliable and efficient performance. The enhancements span across multiple areas including the primary software, 3DCS Variation Analyst, and add-ons Advanced Analyzer and Optimizer, and Compliant Modeler, offering a comprehensive upgrade to your existing 3DCS suite.

3DCS Variation Analyst is a CAD-integrated tolerance analysis software developed by Dimensional Control Systems (DCS). It allows engineers and manufacturers to simulate, analyze, and optimize the variation in assemblies before anything is built—helping to reduce defects, scrap, and rework.

3DCS Variation Analyst is part of the Sandvik End-to-End Solution, bridging design, metrology, and manufacturing under the principles of Quality 4.0 and advancing enterprise-wide quality through a Model Based Enterprise framework.

3DCS 8.2 introduces several new tools designed to elevate the precision of your tolerance analysis.

Among the key modeling advancements are the new Mean Shift Analysis and Auto Point Projection features. Mean Shift Analysis provides precise mean shift values for each individual contributor, enabling targeted insights into assembly variation. Auto Point Projection streamlines modeling by projecting multiple coordinate points onto their corresponding calculated features in a single automated process.

Additionally, the GeoFactor Analyzer and Critical Tolerance Identifier (CTI) are now available in all four 3DCS configurations - 3DCS Variation Analyst, 3DCS Viewer, 3DCS Design Variation Analyst, and 3DCS Mechanical Variation Analyst, making it easier for users to access these powerful tools without needing an AAO license. These features help identify critical tolerances and optimize your manufacturing processes for improved quality control.

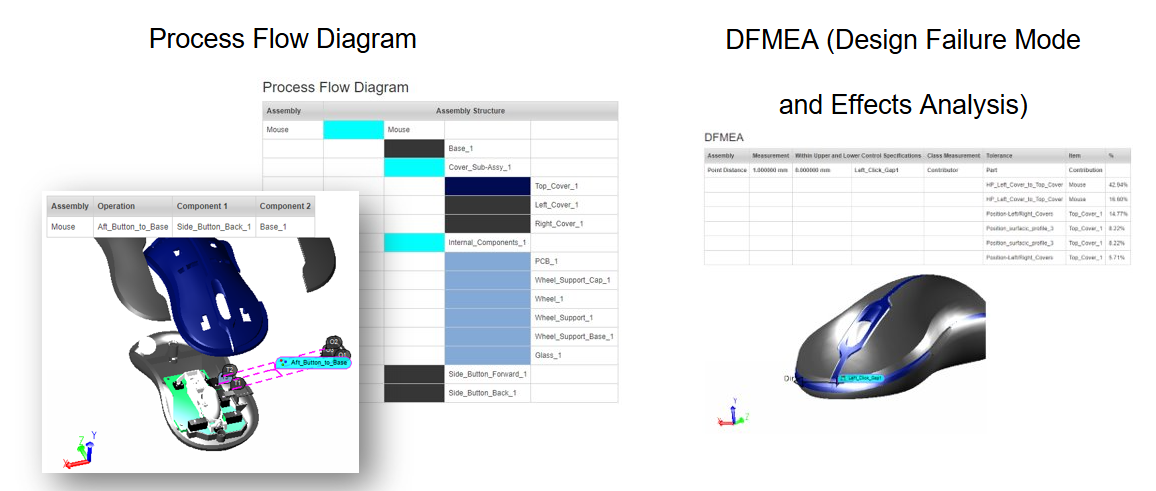

APQP (Advanced Product Quality Planning) is a structured, standardized process used primarily in the automotive and aerospace industries to ensure that a product meets customer expectations from concept through production.

3DCS Version 8.2 introduces enhanced automated reporting capabilities tailored for APQP, providing engineers with specialized tools to efficiently generate the compliance documentation required by industry standards.

User experience has been a key focus in this release. All Move, Tolerance, and Measure dialogs have been redesigned with a Grid-style layout, enhancing usability and streamlining workflows. The new [Add New] button in these dialogs allows users to create a new MTM (Move, Tolerance, or Measurement) seamlessly, without the need to close and reopen the dialog.

The interface improvements extend to the Feature Wizard dialog, now defaulted to Projection for Feature Point update, and a new menu dialog for loading recent HST and HLM files. These changes are aimed at making the software more intuitive and efficient for users, reducing the time spent on routine tasks.

Ensuring compatibility and seamless integration with leading CAD systems, Creo, NX, SOLIDWORKS, CATIA V5, and 3DEXPERIENCE is a priority for 3DCS. Version 8.2 includes updates that support periods and other characters in part names, Alias Display, MTM, and GD&T names, enhancing the flexibility and accuracy of data handling.

These Stories on CATIA

No Comments Yet

Let us know what you think