In the era of Quality 4.0, cross-functional collaboration is the key to unlocking unprecedented levels of efficiency and innovation in manufacturing.

Quality 4.0 represents the integration of advanced technologies such as AI, IoT, and big data into traditional quality management systems (QMS). This integration not only enhances the precision and reliability of manufacturing processes but also necessitates the involvement of diverse teams across the organization. Cross-functional teams bring together expertise from various departments, such as production, quality control, IT, and R&D, to collectively address challenges and drive innovation.

By leveraging the collective knowledge and skills of cross-functional teams, companies can create a more holistic approach to quality management. This synergy ensures that quality improvements are not just limited to isolated pockets within the organization but are implemented across the entire production landscape.

Information silos have long been a barrier to effective quality management. Different departments often operate in isolation, leading to fragmented data and misaligned objectives. Quality 4.0 aims to break down these silos by fostering a culture of collaboration and data sharing. Integrated QMS platforms enable seamless communication and data exchange between departments, ensuring that everyone is on the same page.

By breaking down these silos, organizations can achieve a unified vision of quality. This holistic approach allows for the early identification of potential issues, more effective problem-solving, and continuous improvement across all stages of the manufacturing process.

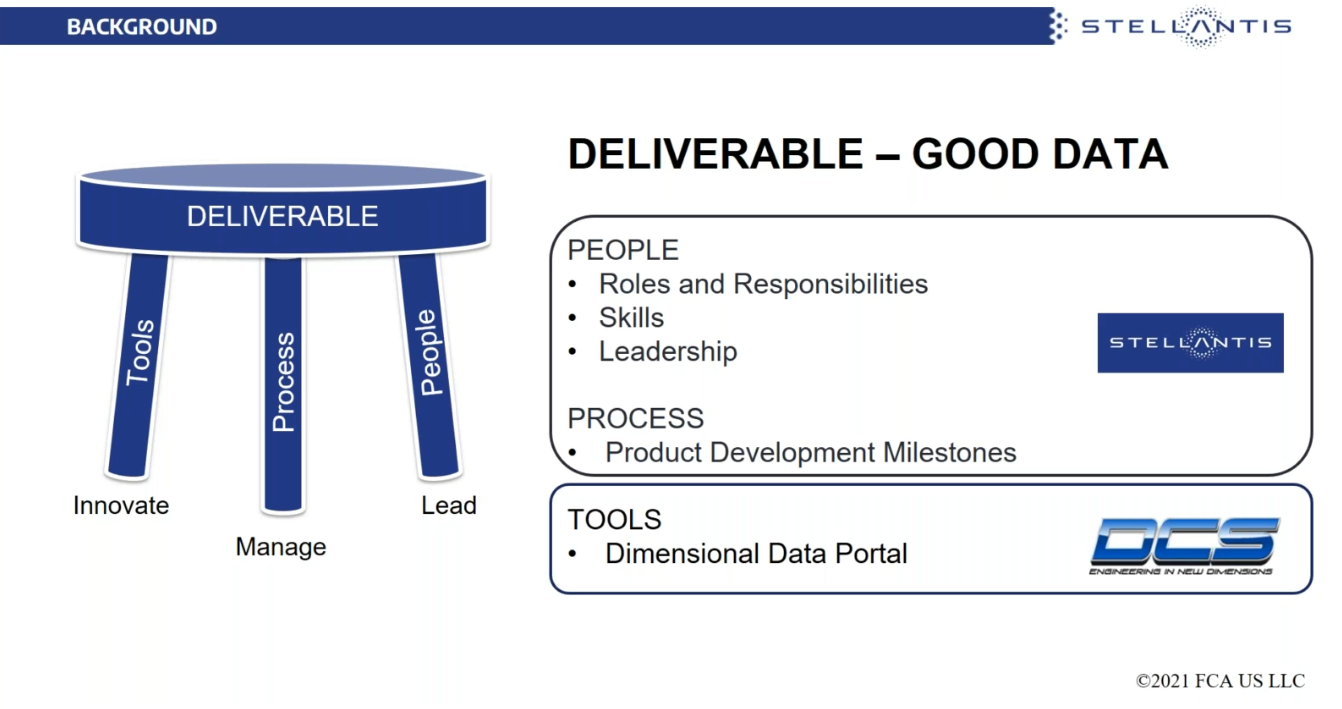

Digital tools play a crucial role in facilitating cross-functional collaboration in Quality 4.0. Advanced software solutions such as Quality Data Management (QDM) systems, Metrology tools, and other digital platforms enable real-time data collection, analysis, and reporting. These tools provide a centralized repository of quality data that is accessible to all relevant stakeholders.

The use of digital tools ensures that quality metrics are consistently monitored and analyzed, enabling proactive decision-making. Furthermore, these tools support remote collaboration, allowing teams to work together effectively, regardless of their physical location. This level of connectivity and transparency is essential for maintaining high standards of quality in modern manufacturing environments.

Several manufacturing companies have already reaped the benefits of cross-functional collaboration in Quality 4.0. For instance, a leading automotive manufacturer implemented a cross-functional quality improvement team that included members from engineering, production, and quality assurance. By working together, they were able to identify and resolve a critical defect in the production process, resulting in a significant reduction in product recalls and warranty claims.

Another example is a consumer electronics company that utilized advanced QMS and metrology tools to enhance collaboration between their design and manufacturing teams. This collaborative effort led to the early detection of design flaws, reducing time-to-market and improving overall product quality.

As technology continues to evolve, the role of cross-functional collaboration in Quality 4.0 is expected to become even more critical. Emerging trends such as the increased use of artificial intelligence and machine learning in quality management will require closer collaboration between data scientists, engineers, and quality professionals.

Additionally, the rise of smart manufacturing and Industry 4.0 will further blur the lines between different departments, necessitating a more integrated approach to quality management. Organizations that embrace cross-functional collaboration and leverage digital tools effectively will be well-positioned to achieve superior quality outcomes and maintain a competitive edge in the market.

These Stories on CATIA

No Comments Yet

Let us know what you think