Unlock the full potential of your manufacturing quality processes by seamlessly integrating SPC Quality Data Management with Dimensional Engineering.

In the manufacturing industry, ensuring product quality and precision is paramount. Dimensional Control Systems (DCS) supports both Statistical Process Control (SPC) and Dimensional Engineering through its robust tools: QDM for SPC and 3DCS for dimensional engineering analysis.

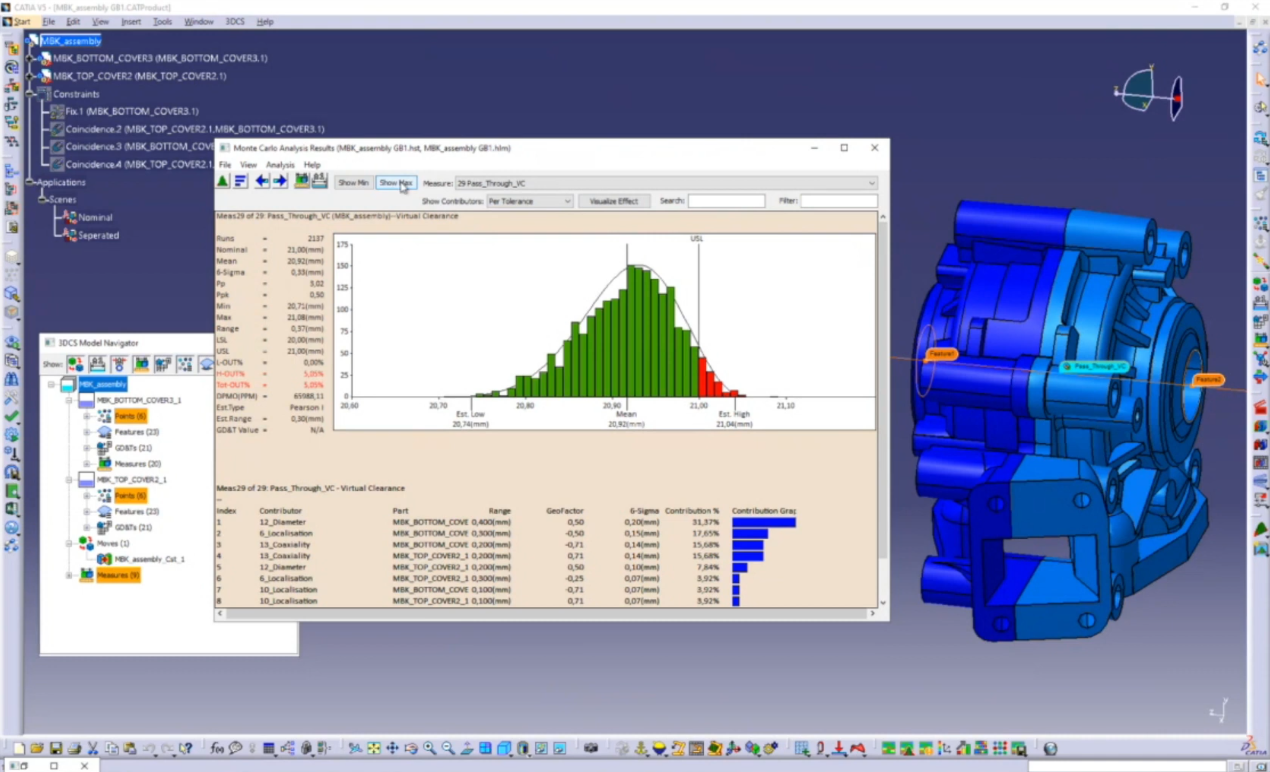

By leveraging QDM, manufacturers can collect, analyze, and visualize quality data in real time, leading to more informed decision-making. Meanwhile, 3DCS enables comprehensive dimensional analysis and simulation, helping teams identify potential issues before they arise. The synergy between these tools ensures a seamless integration of quality data management and dimensional engineering, leading to enhanced product quality and reduced production costs.

Quality Management Systems (QMS) are the backbone of any successful manufacturing operation. Integrating SPC within your QMS provides a structured approach to quality control, allowing for continuous monitoring and improvement of manufacturing processes. By utilizing SPC, manufacturers can detect variations in the production process early and take corrective actions promptly. This proactive approach not only reduces defects but also enhances overall product consistency and reliability.

Moreover, SPC empowers teams with the data-driven insights necessary to optimize production processes. The statistical data gathered through SPC serves as a valuable resource for identifying trends, understanding process capabilities, and making informed decisions. As a result, integrating SPC into your QMS fosters a culture of continuous improvement and operational excellence.

Integrating SPC Quality Data Management with Dimensional Engineering involves several practical steps. First, assess your current quality management processes and identify areas where SPC and dimensional engineering tools can be most effective. Next, implement the necessary software and tools, such as QDM and 3DCS, ensuring that they are fully integrated with your existing systems.

Training your team is also crucial. Ensure that your staff is well-versed in using these tools and understands the importance of integrating SPC and dimensional engineering in their daily operations. Finally, continuously monitor and evaluate the effectiveness of the integration, making adjustments as needed to optimize performance and achieve desired quality outcomes.

Sound like a lot? DCS has services and experts who specialize in these steps, helping you focus on your goals and worry less.

3DCS is a powerful tool used for dimensional simulation and analysis in manufacturing. It allows engineers to create detailed models (digital twins) of their products and simulate the manufacturing process to predict potential dimensional variations. By identifying these variations early in the design phase, manufacturers can make necessary adjustments to ensure that the final product meets all specifications and quality standards.

Simulation plays a critical role in supporting dimensional engineering. It provides a virtual environment where engineers can test different scenarios, evaluate the impact of various factors on product dimensions, and optimize the manufacturing process. This proactive approach helps in minimizing defects, reducing rework, and ensuring that the final product is of the highest quality.

The integration of SPC Quality Data Management with Dimensional Engineering is just one aspect of the evolving landscape of manufacturing quality. Future trends indicate a growing emphasis on automation, advanced analytics, and artificial intelligence in quality management. These technologies will further enhance the ability to predict, monitor, and control quality throughout the manufacturing process.

Events like the Quality Show provide a platform for industry professionals to explore these trends, share insights, and discover innovative solutions. Attending such events can offer valuable opportunities to stay ahead of the curve, network with experts, and gain a deeper understanding of the future direction of manufacturing quality.

These Stories on CATIA

No Comments Yet

Let us know what you think