Discover how cutting-edge data quality management can revolutionize manufacturing processes and boost efficiency.

In today's highly competitive manufacturing landscape, data quality management (DQM) has become a cornerstone for success. Ensuring that data is accurate, consistent, and timely allows manufacturers to make informed decisions, optimize processes, and maintain compliance with industry standards. Without high-quality data, the ability to identify inefficiencies and implement corrective measures is severely compromised.

Moreover, DQM helps in reducing costs associated with poor quality, such as rework, scrap, and warranty claims. By leveraging reliable data, manufacturers can not only improve product quality but also enhance customer satisfaction and trust.

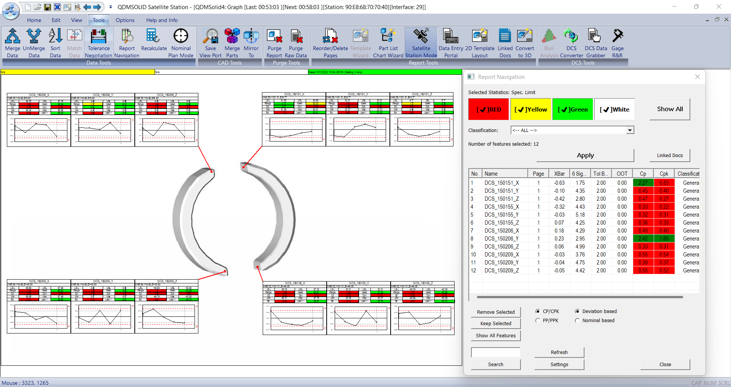

Dimensional Control Systems (DCS), ZeroTouch Metrology, and Metrologic Group are at the forefront of revolutionizing data quality management in manufacturing. These companies offer innovative solutions that streamline data collection, analysis, and reporting, ensuring that manufacturers can maintain high standards of quality and efficiency. By integrating their software and equipment, it makes it easy to get the data you need in a decision-making format to promote quality initiatives.

DCS provides advanced software tools for dimensional engineering and quality data management, while ZeroTouch specializes in non-contact measurement systems that deliver precise data quickly. Metrologic connects the two, offering state-of-the-art metrology solutions that are integral to maintaining data integrity throughout the manufacturing process.

Implementing data quality management offers several key benefits to manufacturers. First and foremost, it enhances operational efficiency by providing accurate and timely data, which is crucial for decision-making. This leads to reduced production downtime and increased throughput.

Another significant benefit is improved product quality. With high-quality data, manufacturers can identify defects early in the production process and take corrective actions before the issues escalate. This not only reduces waste but also ensures that the final products meet or exceed customer expectations.

Furthermore, data quality management helps in regulatory compliance by maintaining accurate records and documentation. This minimizes the risk of non-compliance penalties and enhances the overall reputation of the manufacturing company.

Numerous manufacturers have successfully transformed their operations through effective data quality management. For instance, a leading automotive manufacturer was able to reduce scrap rates and improve first-pass yield after implementing a comprehensive quality management system. This not only resulted in significant cost savings but also enhanced the quality of their vehicles.

The Quality Show offers a unique opportunity to experience the latest advancements in data quality management firsthand. Attendees can expect live demonstrations, interactive sessions, and in-depth presentations from industry leaders like DCS, ZeroTouch, and Metrologic. This is an excellent chance to see how these cutting-edge solutions can be integrated into your manufacturing processes to enhance efficiency and quality.

Additionally, the Quality Show provides a platform for networking with industry experts, gaining insights into best practices, and exploring new technologies that can drive your manufacturing operations forward. Don't miss this opportunity to stay ahead of the curve in data quality management.

These Stories on CATIA

No Comments Yet

Let us know what you think