Exploring the Future of Tolerance Management at Impact Hub Ostrava

On May 14, 2025, the Tolerance Management Forum convened at Impact Hub Ostrava, drawing professionals from the automotive, aerospace, and mechanical engineering sectors. This event served as a platform for discussing advancements in tolerance management and dimensional quality.

Learn more about the forum here: https://tolerancemanagement.bitrix24.site/

The forum featured a series of presentations and case studies:

- 360° Quality: Ulrich Decker from CENIT AG discussed comprehensive approaches to quality, spanning from initial customer inquiries to end-of-life recycling processes.

- Customer Success Stories: Representatives from Edwards, s.r.o., and HELLA AUTOTECHNIK NOVA, s.r.o., shared their experiences and insights into implementing effective tolerance management solutions.

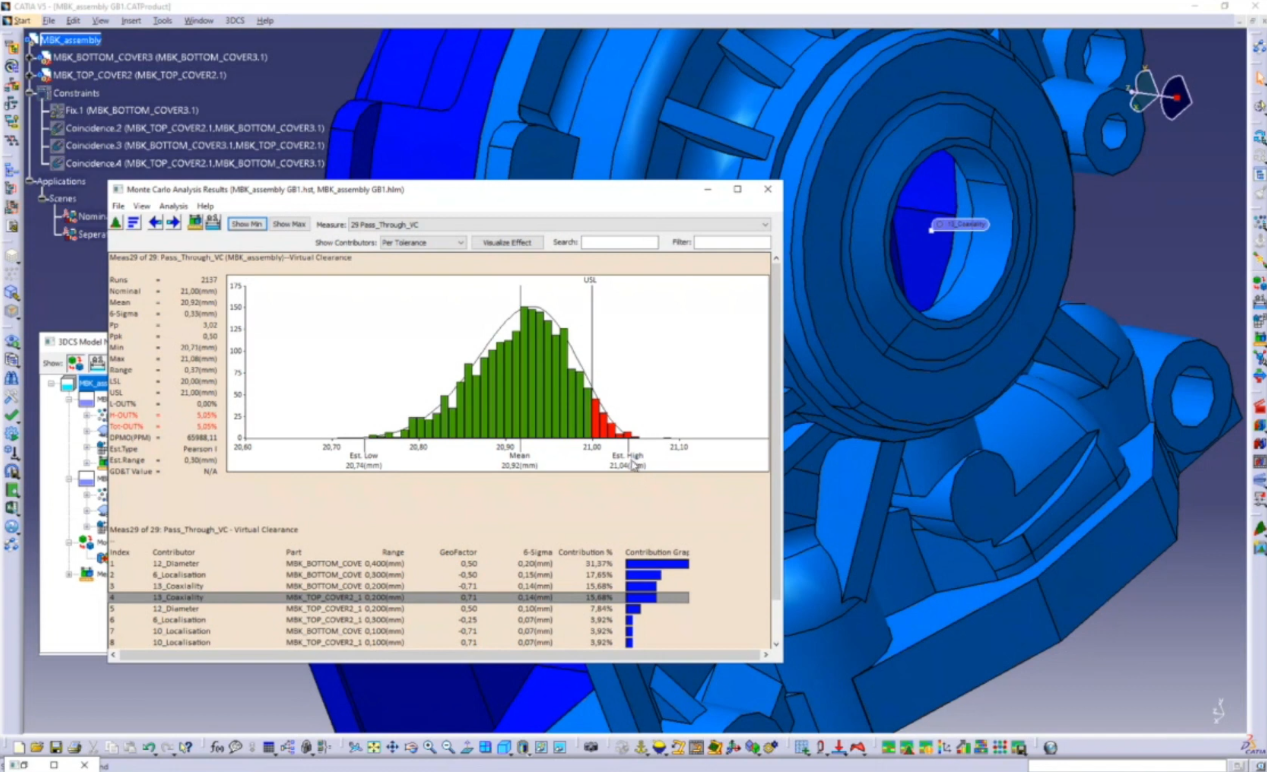

- 3DCS Developments: Dave Johnson of Dimensional Control Systems, Inc. presented the latest advancements in the 3DCS software, highlighting its role in predicting and minimizing manufacturing issues.

Attendees had the opportunity to engage with industry experts, discuss challenges, and explore solutions in tolerance management. The event emphasized the importance of integrating advanced software tools like 3DCS and QDM for real-time quality monitoring and control.

The Tolerance Management Forum underscored the industry's commitment to continuous improvement and innovation in quality assurance practices.

What is 3DCS and How Is It Applied in Manufacturing?

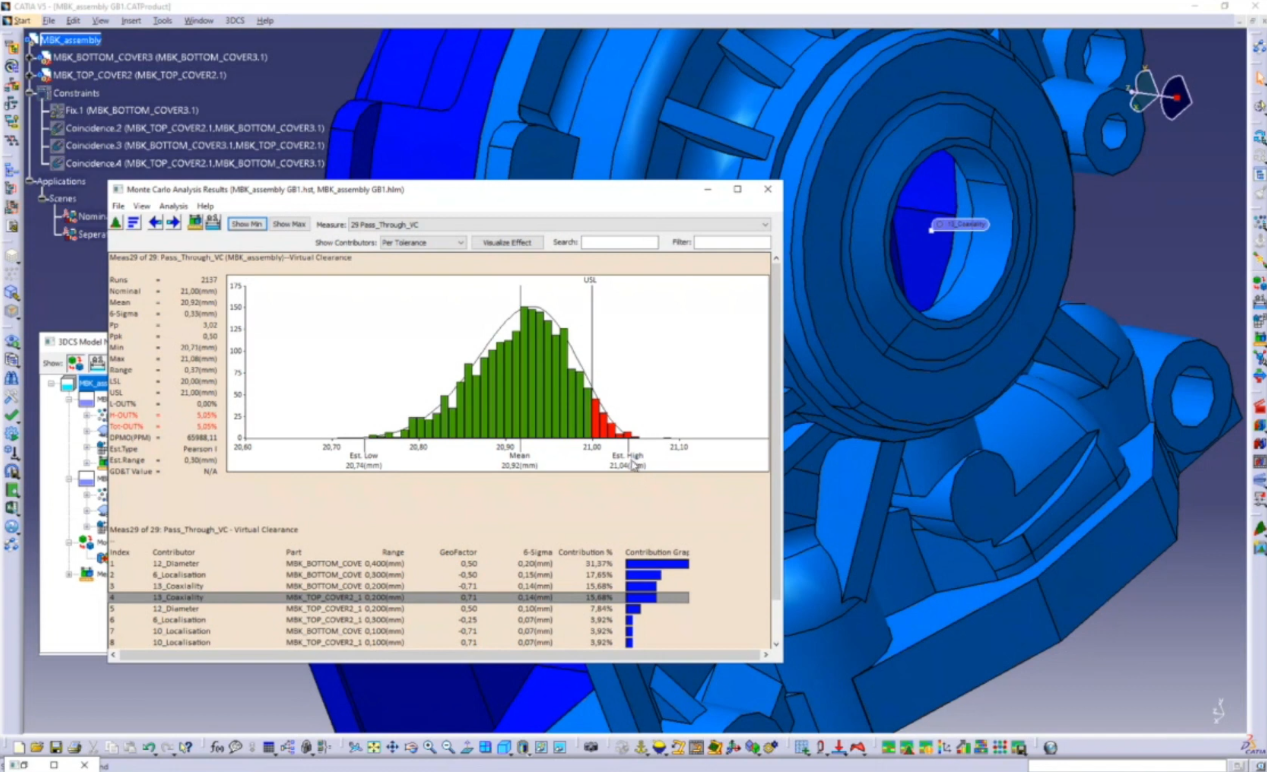

By creating digital twins of assemblies, 3DCS enables manufacturers to:

- Predict and Reduce Defects: Simulate thousands of assembly scenarios to identify potential issues before production begins, reducing the risk of defects and rework.

- Optimize Tolerances: Analyze tolerance stack-ups to determine the optimal balance between manufacturing capabilities and product requirements, leading to cost savings and improved quality.

- Enhance Design for Manufacturing: Incorporate both part and process variations to ensure that designs are robust and manufacturable, minimizing the need for costly design changes later in the production cycle.

By leveraging 3DCS, manufacturers can make informed decisions early in the design process, leading to improved product quality, reduced production costs, and enhanced customer satisfaction.

No Comments Yet

Let us know what you think