There are a number of reasons to adopt GD&T at your company:

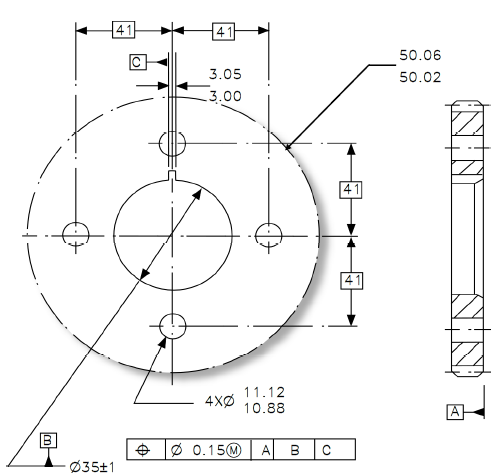

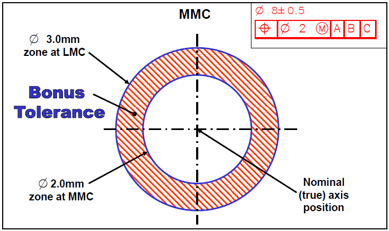

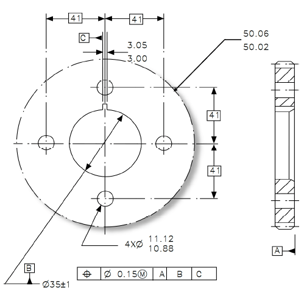

Clarity and consistency in the design process. GD&T provides a clear and concise method for defining a reference coordinate system on a component or assembly that can be used throughout manufacturing and inspection. This reduces misinterpretations, and the need for costly engineering changes and rework that can result from a lack of clarity.

Dramatic time savings. By using GD&T, engineers dramatically reduce their need for drawing notes to describe complex geometry requirements on components and assemblies.

Dramatic time savings. By using GD&T, engineers dramatically reduce their need for drawing notes to describe complex geometry requirements on components and assemblies.

Fit with accepted design-for-manufacturing methods. The proper application of GD&T closely dovetails accepted and logical mechanical design processes and design-for-manufacturing considerations. For example, the allowable variations as defined through GD&T can be directly read, or “imported,” into 3D tolerance analysis software such as 3DCS.

Offered through use of a variety of tools - shared pdf's, ppt, and screen sharing software Gotomeeting and Gotowebinar to provide an interactive class. Classes are broken up over additional days to reduce each class length, allowing students to continue their other responsibilities while also attending the course.

This 2 - day course comprising a basic fundamental geometric dimensioning and tolerancing (GD&T). This course is an introduction of the geometric dimensioning and tolerancing (GD&T) aimed at developing the participants understanding of the symbols and standards.

This course is ideal for individuals who interpret engineering drawings including design, layout, assembly, checking and inspection personnel. Beginning designers, drafters, quality, procurement, tooling, production, manufacturing and shop personnel; designers, and others involved with tooling, production, and inspection.

This 2 - Day course is focused on practical applications of GD&T for real world experience. This course focuses on the application and development of Geometric Dimensioning and Tolerancing in your application, on your drawings.

This course is ideal for professionals who use the ASME Y14.5 Dimensioning and Tolerancing standard, who work in design, drafting, quality, procurement, tooling, production, and manufacturing

Paul is a Design for Six Sigma (DFSS) Master Black Belt. Former GM DFSS Global Process Guardian, Paul led the global DFSS team developing people, methods and tools. Paul was Global Epsilon Vehicle Architecture Manager responsible for design and manufacturing integration.

Paul is a Design for Six Sigma (DFSS) Master Black Belt. Former GM DFSS Global Process Guardian, Paul led the global DFSS team developing people, methods and tools. Paul was Global Epsilon Vehicle Architecture Manager responsible for design and manufacturing integration.

As Dimensional Engineering Program Manager and Dimensional Analysis Lead, Paul was responsible for and developed tools and methods for product and process, fit, finish and function for the global Delta Program. Paul led the development of the GM Global Bill of Process resulting in piece cost, investment, and mass reductions with improved quality.

Paul has a proven track record in resolving cross functional quality issues in

body shops, general assembly and powertrain. Paul led the problem solving

team for the T1 Truck, Kappa, P90 and J car programs. An expert in multi variable statistics, Paul brings a powerful tool box of statistical methods including Red X, Six Sigma, reliability, SPC, PCA, MTS, and DOEs.

These Stories on CATIA

No Comments Yet

Let us know what you think