DCS is a quality software company that develops tolerance analysis software and SPC quality systems for manufacturers.

The event includes a quick tour of the DCS offices and a presentation by three of the DCS staff.

1. Brief Introduction

2. New 3D Tolerance Simulation

3. How Tolerance Analysis Drives Model Based Definition

5:30 PM — Arrival, professional networking and meal

6:00 PM — Tour & Presentation

7:30 PM — Questions and Answers

With more than twenty years of experience helping customers in the automotive, aerospace, medical device, electronics, and heavy machinery industries, DCS has worked with major manufacturers like Airbus, Boeing, General Motors, FCA, Philips Medical, LG, SAMSUNG, Jaguar Land Rover to reduce the costs of quality: scrap, rework, warranty claims.

DCS is proud to showcase the new release of 3DCS software as well as the new fully integrated 3DCS for SOLIDWORKS.

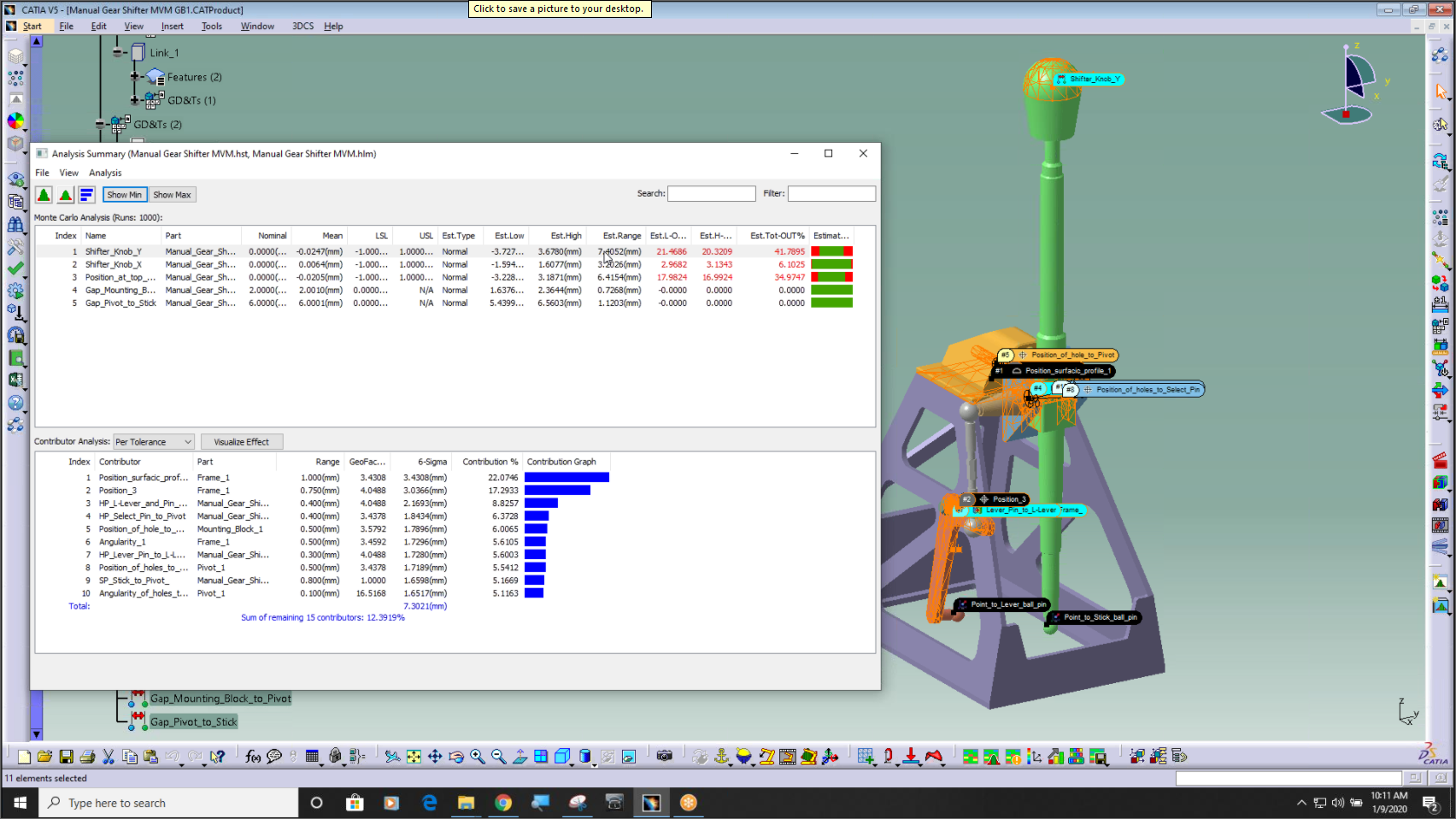

3DCS Variation Analyst for SOLIDWORKS is a fully integrated scale-able tolerance analysis solution set that simulates product assembly and manufacturing processes, as well as part tolerances, in a 3D stack-up through several types of analysis; Monte Carlo Simulation, sensitivity, equation-based, and worst case analysis.

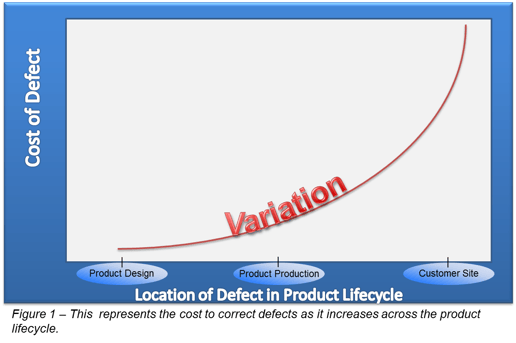

There is a huge cost to not doing things right the first time. There is a cost in design, in manufacturing, in reworking, or just throwing parts away. Downstream, bad perception of your products, and product failures can cause expensive fixes.

“Our business,” Donald Jasurda, DCS VP of Sales said, “across everything we do, it is about one thing and that is controlling the cost of quality. I think about this type of analysis as something that is a standard activity in the automotive and aerospace structures industries, and is becoming, evolving in medical device and industrial machinery and electronics packaging. The cost of scrap and rework and the impact it has on profit margins drives this evolution, as in the automotive industry, the margins are very thin and improving product design through simulation is an opportunity to save money.”

On the production side of things, professionals have grown accustomed to using statistical methods like SPC for decades. The use of tolerance analysis is really nothing different than simulating SPC in a virtual environment with Digital Twins, and doing that work as part of the design process.

Join DCS on March 11th to eat and mingle with their team, as well as learn how 3DCS software is used to reduce costs and improve quality across the product life cycle.

Please RSVP by March 10th to Benjamin Reese –

breese@3dcs.com or call 248-269-9777.

Address: 5750 New King Dr. suite 330 (3rd floor), Troy MI 48098 USA

These Stories on 3DCS

No Comments Yet

Let us know what you think