Discover how Capvidia and DCS are revolutionizing FAI reporting with their new collaborative solution.

FAI (First Article Inspection) reporting plays a crucial role in the manufacturing industry. It is a quality control process that ensures the initial production run of a new product meets all the required specifications and standards. By conducting FAI reporting, manufacturers can identify any issues or discrepancies early on in the production process, preventing costly errors and ensuring that subsequent production runs meet the desired quality standards.

FAI reporting is especially important in industries that require high precision and accuracy, such as automotive, aerospace, and medical device manufacturing. It provides a systematic and standardized approach to verifying the design and manufacturing process, reducing the risk of defects and ensuring compliance with customer requirements and regulatory standards.

In addition to ensuring product quality, FAI reporting also serves as a documentation and record-keeping process. It provides a detailed report of the product characteristics, measurements, and test results, which can be used for future reference, audits, and customer reviews. Having accurate and comprehensive FAI reports is essential for maintaining regulatory compliance and demonstrating product reliability and traceability.

Traditional FAI reporting processes often involve manual data collection, analysis, and documentation, which can be time-consuming, error-prone, and inefficient. Some of the key challenges faced in traditional FAI reporting processes are:

- Manual data entry and transcription errors: The reliance on manual data entry increases the risk of typographical errors, leading to inaccurate measurements and calculations.

- Disparate data sources and formats: FAI reporting requires gathering data from various sources, such as CAD models, inspection reports, and measurement devices. Integrating and reconciling data from different formats and systems can be challenging and time-consuming.

- Lack of real-time collaboration: Traditional FAI reporting processes often involve multiple stakeholders, including design engineers, quality engineers, and production teams. Coordinating and communicating changes and updates in a timely manner can be difficult, leading to delays and miscommunication.

- Limited traceability and auditability: Traditional paper-based FAI reports can be easily misplaced, damaged, or lost, resulting in a lack of traceability and auditability. This can make it challenging to track the history of product inspections and comply with regulatory requirements.

Addressing these challenges is crucial for improving the efficiency and effectiveness of FAI reporting processes, ensuring accurate and timely inspections, and reducing the risk of quality issues.

To address the challenges faced in traditional FAI reporting processes, Capvidia and DCS have joined forces to create a new collaborative solution. Capvidia is a leading provider of 3D visualization, validation, and collaboration software, while DCS is a trusted provider of quality management and inspection software solutions.

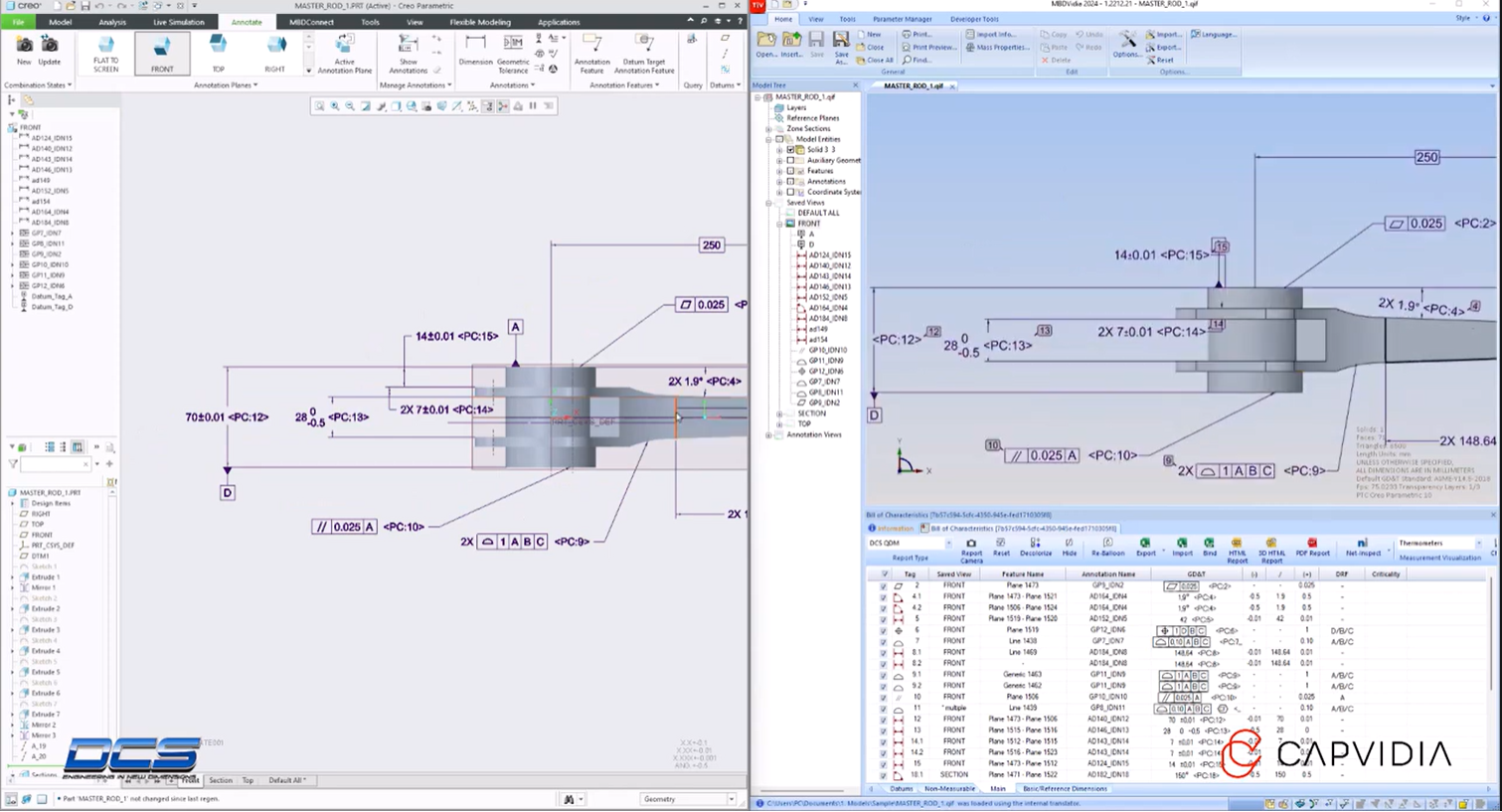

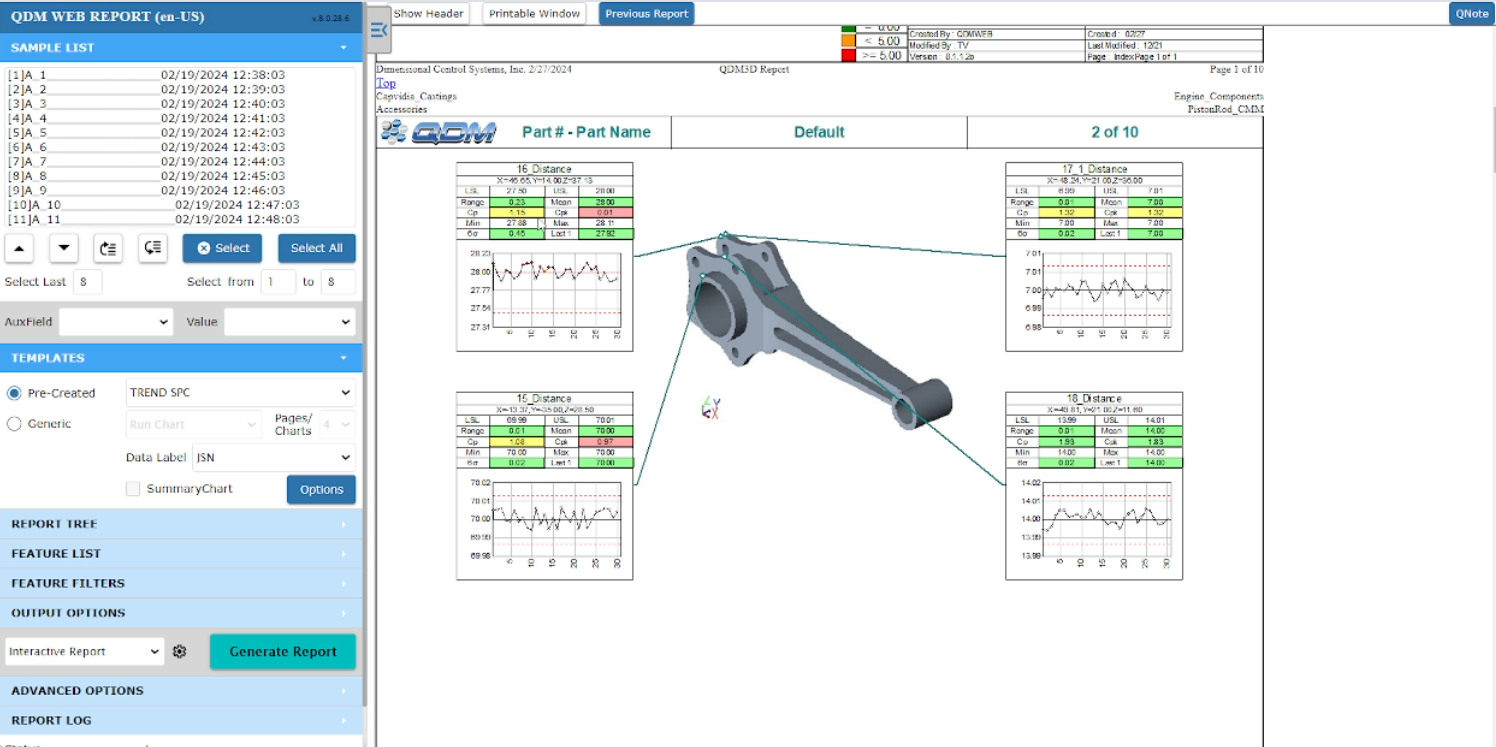

The collaborative solution combines Capvidia's expertise in 3D visualization and validation with DCS's robust quality management and inspection capabilities. It offers a streamlined and integrated approach to FAI reporting, leveraging advanced technologies such as CAD integration, automated data collection, and real-time collaboration.

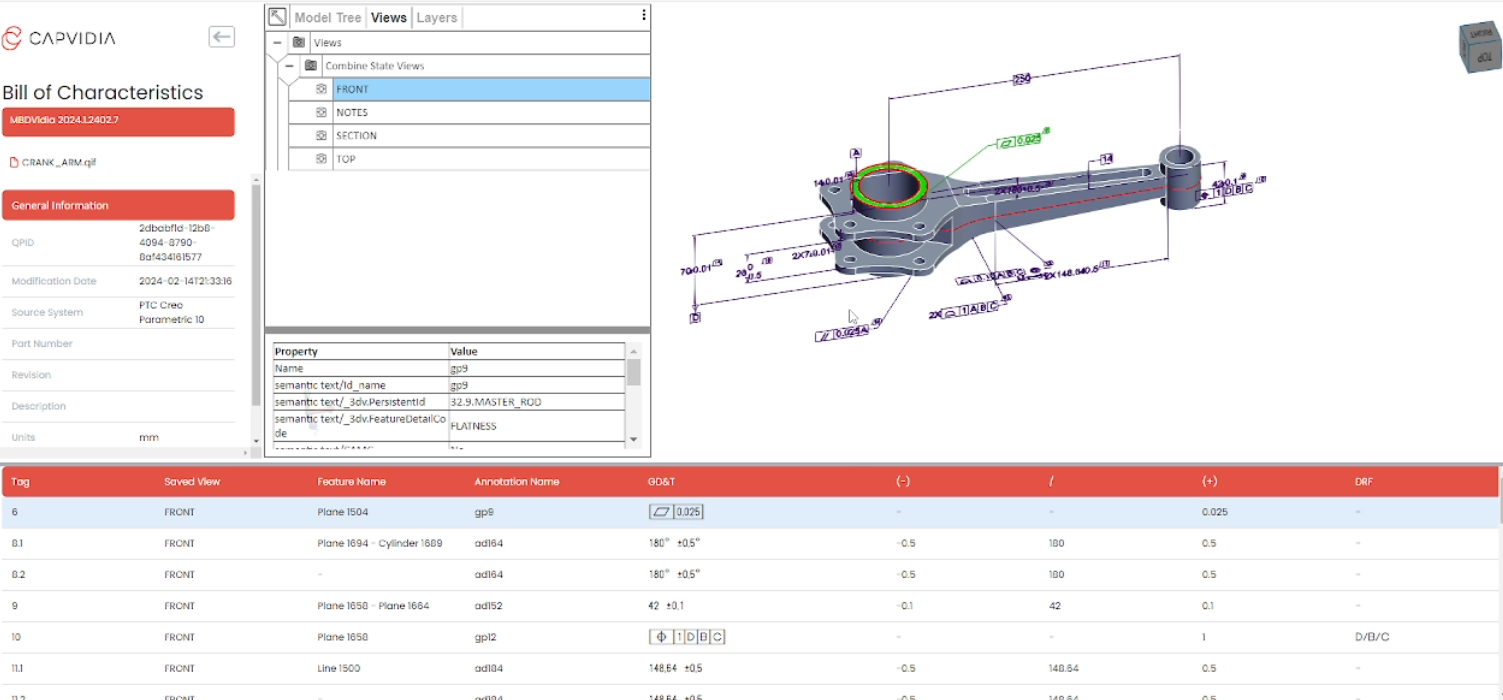

By integrating CAD models directly into the FAI reporting process, the solution enables automatic extraction of product characteristics and measurements, eliminating the need for manual data entry and reducing the risk of errors. The solution also supports seamless integration with measurement devices, enabling direct data capture and real-time analysis.

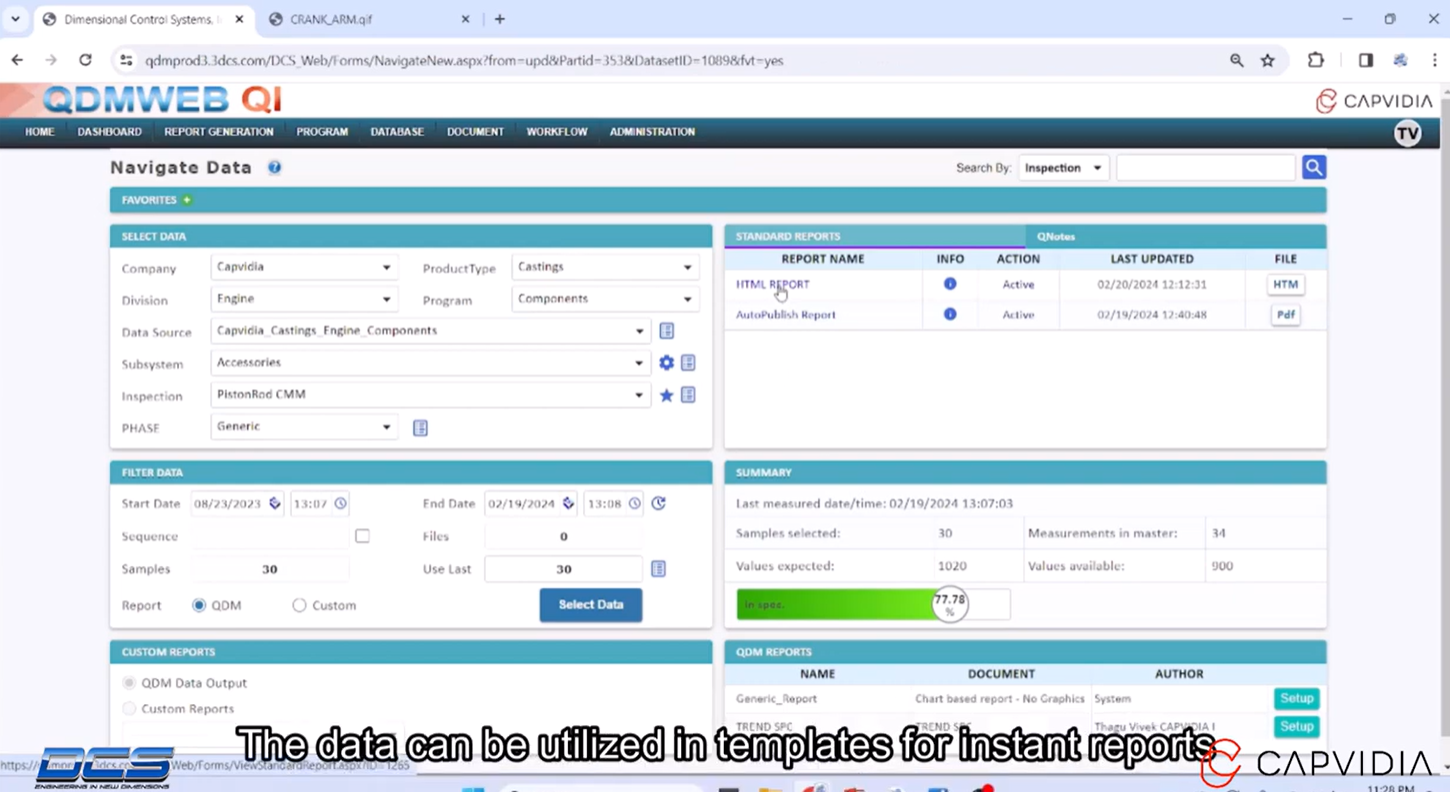

Furthermore, the collaborative solution provides a centralized platform for all stakeholders involved in the FAI reporting process. It allows for real-time collaboration, ensuring that design changes, inspection results, and updates are communicated and documented efficiently. This improves communication, reduces delays, and enhances overall productivity.

With the introduction of Capvidia and DCS's collaborative solution, manufacturers can benefit from improved accuracy, efficiency, and traceability in their FAI reporting processes. It enables faster inspections, reduces the risk of errors, and enhances overall product quality.

The new FAI reporting solution developed by Capvidia and DCS offers several key features and benefits:

- CAD integration: The solution seamlessly integrates with CAD models, allowing for automatic extraction of product characteristics and measurements. This eliminates the need for manual data entry and reduces the risk of errors.

- Automated data collection: The solution supports direct data capture from measurement devices, eliminating the need for manual data transcription. It ensures accurate and real-time measurement data for FAI reporting.

- Real-time collaboration: The solution provides a centralized platform for all stakeholders involved in the FAI reporting process. It enables real-time collaboration, ensuring efficient communication and timely updates.

- Streamlined documentation: The solution automates the generation of FAI reports, ensuring standardized documentation and reducing the risk of misplaced or lost reports. It enhances traceability and auditability.

- Improved efficiency: By eliminating manual data entry and streamlining the FAI reporting process, the solution improves overall efficiency. It reduces inspection time, minimizes errors, and enhances productivity.

These key features and benefits of the new FAI reporting solution contribute to improved accuracy, efficiency, and collaboration in the manufacturing industry, revolutionizing the way FAI reporting is conducted.

The introduction of a streamlined FAI reporting solution has significant implications for the manufacturing industry. By leveraging advanced technologies and automation, manufacturers can expect the following future impacts and potential benefits:

- Increased productivity: Streamlined FAI reporting processes save time and effort, enabling manufacturers to conduct inspections more efficiently. This leads to increased productivity and faster time-to-market for new products.

- Enhanced product quality: By reducing the risk of errors and improving documentation, streamlined FAI reporting processes contribute to enhanced product quality. Manufacturers can identify and address issues early on, ensuring that the final product meets all required specifications.

- Improved regulatory compliance: Accurate and comprehensive FAI reports are essential for regulatory compliance in industries such as automotive and aerospace. Streamlined FAI reporting processes enhance traceability and auditability, making it easier for manufacturers to comply with regulatory requirements.

- Cost savings: By minimizing errors, rework, and scrap, streamlined FAI reporting processes help manufacturers save costs. The early detection of issues and the ability to make timely adjustments result in more efficient production runs and reduced waste.

- Continuous improvement: Streamlined FAI reporting processes provide manufacturers with valuable data and insights. By analyzing FAI reports, manufacturers can identify trends, patterns, and areas for improvement in their design and manufacturing processes, driving continuous improvement.

In conclusion, the collaboration between Capvidia and DCS to create a new FAI reporting solution is set to revolutionize the manufacturing industry. By addressing the challenges of traditional FAI reporting processes and leveraging advanced technologies, manufacturers can improve efficiency, accuracy, and collaboration in their FAI reporting, ultimately leading to enhanced product quality and customer satisfaction.

These Stories on CATIA

No Comments Yet

Let us know what you think