SPC sounds amazing, especially from the vendors that provide it (we're guilty too). It promises all kinds of benefits:

Achieving these benefits is another matter entirely. Digital Transformation adds powerful tools to your organization and SPC is an important part of this move. As the news demonstrates, though, not all Digital Transformation is successful. This is because altering processes and adding new tools is a difficult task. IN addition to the IT issues with new software and systems, people don't want to do things differently, or use new systems that might require complicated workflows.

At The Quality Show in Chicago, we were able to meet and discuss with small, medium, and large manufacturers about their Digital Transformations (SPC in particular), and the barriers standing in the way.

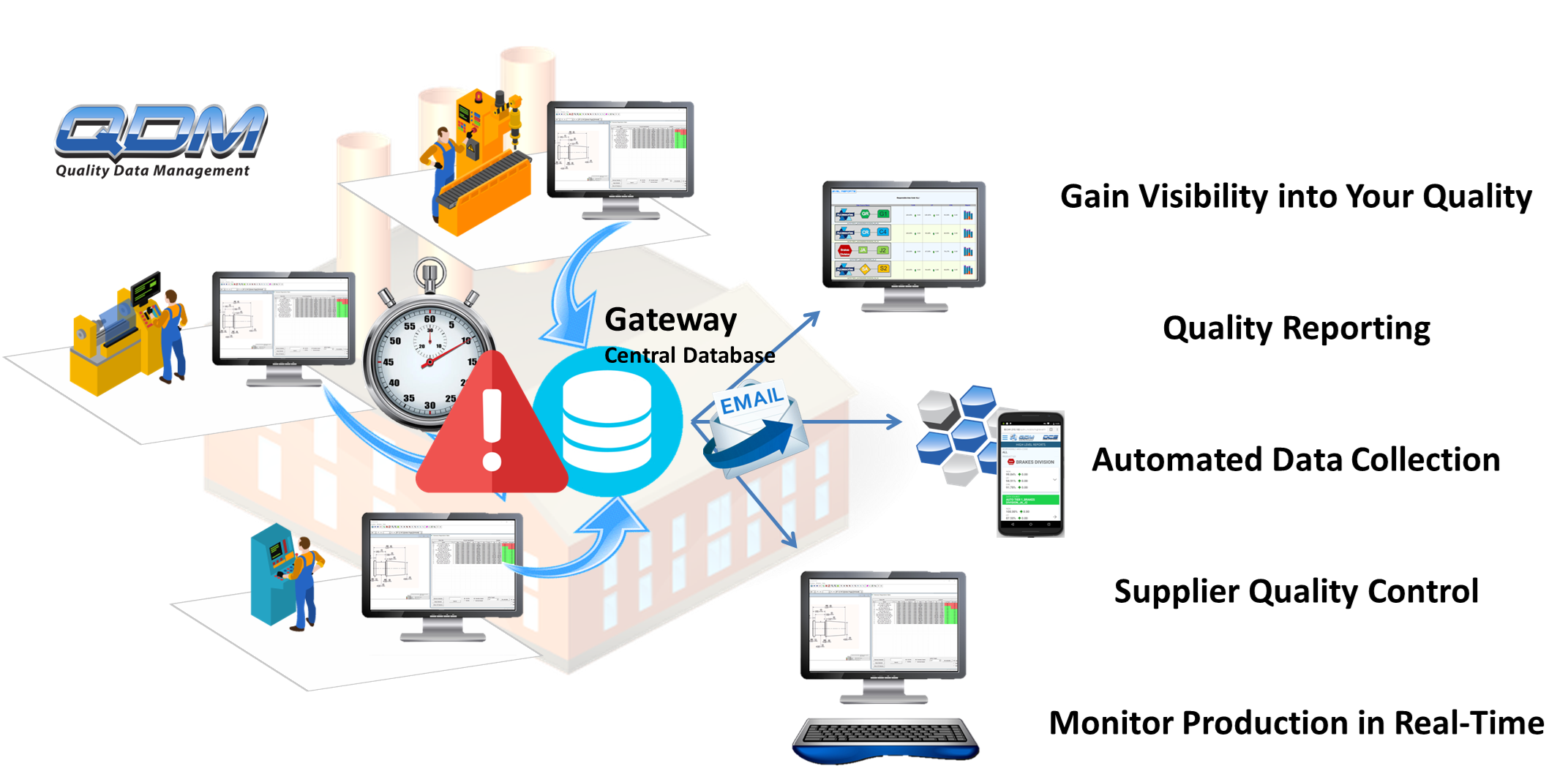

DCS was proud to showcase a live QDM machine shop system at The Quality Show, showcasing its ability to create a Digital Twin of the quality process and provide tools at both the plant floor and the manager level to catch quality issues as they begin to develop, and to resolve them quickly and efficiently.

“From a quality perspective, what we’ve been doing with measurement data analysis and monitoring is really a digital twin of the quality process that has been going on for years,” Don Jasurda, DCS Vice President says. “It is now practical to do that with the plant, all their equipment, plant structure, and layout. They want digital twins of everything to make effective use in the same way people have been using digital representations of quality results for years.”

Let's get right to why you're here; what were the barriers to SPC we encountered at The Quality Show?

It's too expensive

My data is in drawers somewhere - manual recording of measurements

I don't want to change our workflows or processes for a new system

We're not ready for SPC

I wouldn't know where to start

We don't want to get SPC, it only works with one type of machine

SPC Systems can be very expensive. When you include training, and implementation, as well as adoption slowdowns, the expenses can be vast. This is why it can be helpful to start small, and begin with one part of the organization; testing the new system and determining initial outcomes.

This is fairly obvious, but not all SPC systems can support a small implementation, or do so according to an organization's workflows.

QDM SPC systems are modular, and allow organizations to begin with a couple small modules to test out the value of SPC information, and their ability to incorporate the tools into their workflows.

Beginning at a single plant, or even smaller with a single team at the plant, can be a good way to set up a test bed. Data can be manually driven to the SPC tools, or set up for automated reading, depending on the budget for the evaluation. Sharing this information to provide snap shot insight into production gives everyone involved visibility into production issues, trends, and machine wear.

As a secondary implementation, SPC tools can be used to drive workflows. Utilizing an SPC tool like QDM ANALYST to determine problem areas or trending non-conformances, these can be tagged and assigned to teams in order to create a Corrective Action Workflow utilizing SPC data and measurement data to specify where the problem is, and what needs to be done to correct it. These actions can then be assigned to groups, and passed along for the fix. This streamlined communication can connect groups more efficiently to reduce the time it takes to both find and correct problems.

These kinds of small starter systems are inexpensive to implement and purchase, and can provide a lot of value immediately, especially in a scenario where no SPC systems or tools were in place beforehand.

A lot of manufacturers Quality Managers struggle to get the data they need to make determinations and support decisions. If pass/fail is the only criteria being checked, with hand gages or a check fixture, it can miss trending issues. These can lead to the first problem being found when a series of failures occur, which can slow, or even stop, production dead in its tracks. This could have been resolved without any bad parts produced if the production was watched more closely. SPC Systems provide this kind of insight, showing not just when parts are good and bad (pass/fail) but can show when parts trend towards an Upper or Lower Spec Limit and notify quality professionals far ahead of any failures.

If your data is being recorded on a clip board and dropped into drawers, how do you get access to it in order to even use an SPC tool?

First thing's first, creating a method to get the data into the SPC tools. QDM SPC provides two primary methods of getting disparate data into your system for use:

First thing's first, creating a method to get the data into the SPC tools. QDM SPC provides two primary methods of getting disparate data into your system for use:

Data Entry Portal creates a workstation that can used for manual input of data into the system. This workstation will ask for the information you need in order to monitor your quality, but not so much that it becomes tedious. Oftentimes, a part number, the machine and measurement are all that is needed. The system creates a time stamp, and if it isn't mobile, can be assigned to a specific machine to automatically fill that information. This makes the process simple, either type in the measurements as you make them, keeping the system immediately up-to-date, or record on your clipboard and then fill in the information at the station afterwards. Getting this data into the system allows all of the other connected tools to use, report, and analyze the data, providing immediate actionable information to both the plant floor and the quality team.

Datagrabber is a module that automates data collection. It reads in files from your network at given time intervals or at trigger events to keep your system up-to-date. Datagrabber can be configured to monitor folders and Excel files, grabbing the data within when the files are updated, or at set times (like every 5 minutes, or every morning and afternoon). Using Datagrabber lets your operators update an Excel sheet with their measurement data, and when they click save, Datagrabber will pull the new data into your SPC system, updating your dashboards, reports, and instantly analyzing the data for SPC.

This is a loaded statement. You shouldn't have to change your workflows and processes when bringing in a new system. The system should be fit into your existing processes to improve their efficiency and provide a more stable and reliable method of communicating across the organization.

QDM SPC supports this by being set up as a modular system. Modules are chosen, like creating an assembly line, based on the tasks needed at each area of the organization. Like purchasing a machine, you choose the machine that is needed at that stage in production, whether it is a machining operation, CNC, or milling machine, QDM SPC provides a tool kit that offers organizations the ability to choose the module that fits the needed operation. This includes Satellite Stations that display constantly refreshed reports on the plant floor, to Data Entry Portals to support manual data collection, to interface handhelds (tablets) for mobile, easy access to the Web Portal for dashboards and custom reports. With each interface being customizable to specific users, tasks, or areas, QDM SPC lets you determine how the system fits your organization, instead of trying to fit the organization to the system.

This is a common response. I wouldn't call it an excuse, as SPC can be understandably intimidating, and some small manufacturers that produce the same parts over and over again have their process streamlined enough that they have few errors, and know when they need to maintain their machines. Most manufacturers, though, can get value from doing even basic SPC.

Not being ready for SPC is generally one of two situations; either apprehension at trying to apply SPC tools, or disinterest in the tools because of a lack of perceived value.

Apprehension is understandable. SPC can be daunting, as too often, people and organizations try to do too much at once, and overwhelm their own team. For large organizations, a bigger deployment makes sense with large quality teams and budgets, but for smaller organizations who may not have SPC and nearly as many quality specialists available, a smaller, controlled application helps get the team on board and prove out the value. When tools help people get their job done, and more importantly, save them from having to deal with troublesome problems by predicting them early, or do painfully repetitive and time-consuming tasks, they will quickly win over hearts and minds.

A disinterest in the tools because of a lack of value is often a different issue altogether. Traditional methods work, and many manufacturers have done things the old fashioned way of fixing problems when they come up and using experience to address both the source of those issues and the solution. This is a short sighted methodology though, as globalization and the inclusion of more technology are not only increasing the number of competitors in the market, but also giving competitors, local and abroad, tools to produce the same products cheaper. They are doing this by removing the cost of tackling problems that are now caught and resolved early with SPC, and bring their products to market faster by reducing the need for rework, prototypes, and test runs. It becomes a matter of self-destruction to ignore the technology trends, and risks going the way of the typewriter; it works and provides the same basic service as a computer, but makes corrections difficult, copying a problem, and the application of other services impossible. You can't send an email with a typewriter, and you can't successfully compete internationally without effective quality control.

This kind of answer makes perfect sense. You know you need to do it, but where do you start with a topic as complex as SPC? Let me be more specific, what tools, software, processes, and applications do you purchase and apply in order to start using SPC? The statistics and outputs themselves are well known to professionals in the industry, but there are dozens of vendors and providers for SPC tools and software systems.

This is a more complex answer than a simple point and click. It is often best to map out your processes, and determine where the production bottlenecks are, and where the majority of production issues happen. Working backwards from there is a good place to begin. Most SPC providers can help with a Quality Audit, essentially doing this as a service. Finding these trouble areas allows for the SPC system to provide the most immediate return on investment, targeting the 'low hanging fruit' in your process that is creating the most waste and working to give your team the tools to reduce and control that waste.

Many machine makers also provide SPC software. These systems can work with 3rd party devices, but are not designed to do so. They work best when in a completely unified environment. This can be a turn off for many manufacturers who have refurbished machines or equipment, or who have a collection of devices from different manufacturers.

Companies that focus on SPC software, and not hardware, may provide a better solution. These tools are designed from the ground up to handle a non-uniform environment, often coming with translators for a large number of common measurement and inspection devices. These tools can be plugged into any environment and connected into the ecosystem without the need for complicated connections or manual data passes because of multiple brands of equipment being present. By choosing one of these providers, manufacturers can side-step the need to stay with a particular machine brand, and dodge the problems with compatibility when using their full suite of hardware tools already present at their plants.

The Best Way to Begin is to Work With Someone You Can Trust

SPC is a daunting task. With the amount of information now out in the marketplace, the task of starting SPC at your organization can feel insurmountable. Finding a vendor that understands these early stages and determining your current quality workflows and bottlenecks is important to get started with any new quality initiative. DCS has helped many manufacturers, large and small, tackle their quality challenges and successfully implement SPC systems. If SPC is something you want to start, feel free to reach out to us, and we can help answer questions and provide some direction to starting your project.

These Stories on SPC

No Comments Yet

Let us know what you think