Larger enterprises are beginning to deploy Statistical Process Control (SPC) software solutions independent of their investments in Manufacturing Execution Systems (MES), Enterprise Quality Management Software (EQMS) and Enterprise Resource Planning (ERP) systems.

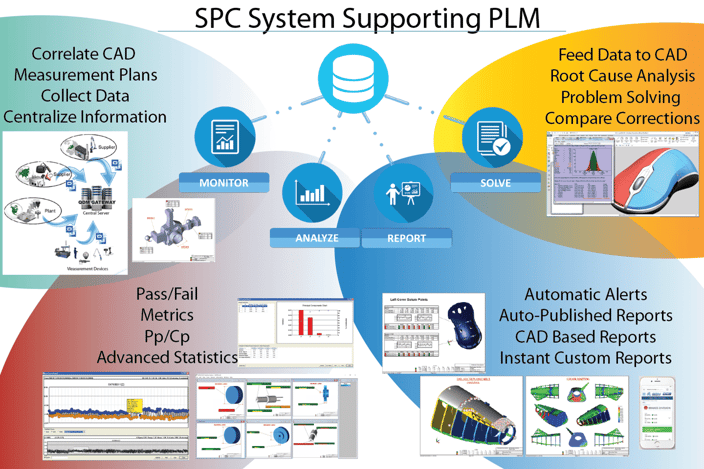

SPC software assists manufacturers by providing them with data collection and workflow analysis capabilities to help improve and reduce variability in production processes. Typical users of SPC include Six Sigma project managers, continuous improvement professionals, manufacturing supervisors and machine operators.

While using SPC software has the potential to increase a manufacturer's production efficacy and quality control drastically, it can be difficult for manufacturers to find the right SPC software vendor for their company.

In this article, the experts at Dimensional Control Systems go over what SPC software is, how exactly manufacturers can benefit from using it, and how manufacturers can choose the right SPC software vendor for their needs.

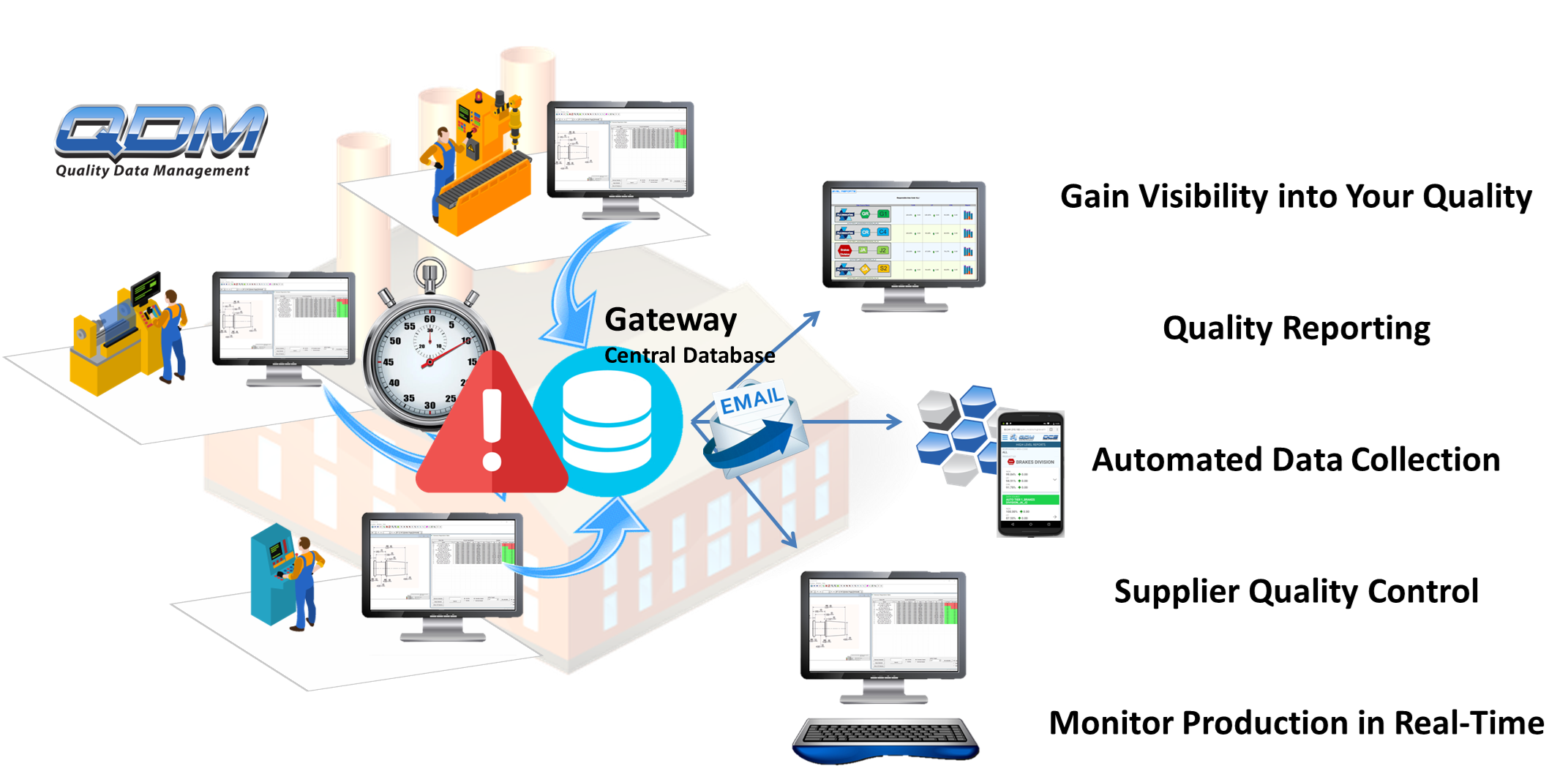

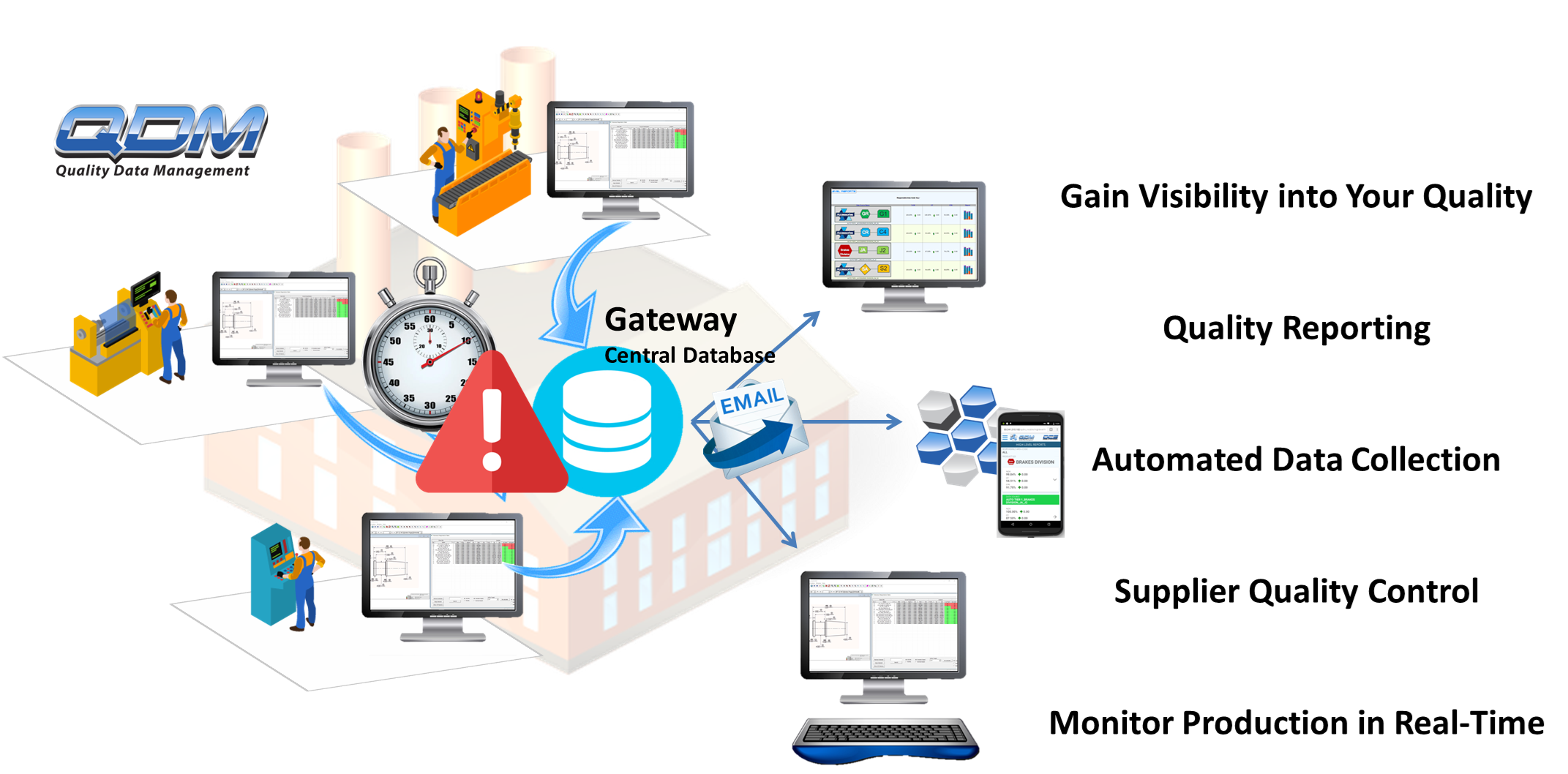

SPC software can largely be seen as a symptom of Industry 4.0, the fourth industrial revolution that many industry experts posit is currently taking place. SPC software is sold either as SaaS (software-as-a-service) as a cloud installation or as a permanent license with an on-premise installation (company server) and provides manufacturers with a software platform that stores and aggregates real-time data about every element of a production pipeline simultaneously.

The true benefits of using SPC software can perhaps most easily be seen in how drastically SPC software can improve an enterprise's quality control and production efficacy. Typically, manufacturers break production pipelines into sectors.

Unfortunately, problems that arise in those sectors are often caught later rather than sooner - as a result, a malfunctioning pipeline element can sometimes lead to millions of dollars in lost revenue and product.

Because SPC software is constantly aggregating and tracking the status of pipeline elements, even as minutely as on a part-by-part basis, manufacturers can constantly evaluate every aspect of a production pipeline, and can immediately shut down or divert production the instant an issue arises.

As a result, SPC software not only greatly improve product control and the efficacy of pipeline repairs and functions, but also by proxy improves revenue, customer satisfaction, regulations-compliance, and stakeholder confidence.

One of the best examples of SPC software in action is this African gold mine that saved $20 million annually and increased their yield by 3.7 percent by using SPC software to identify and address an inefficiency within their production pipeline. This example demonstrates the value of SPC outside of traditional manufacturing sectors (like automotive) where it is most expected. With even small production numbers, SPC can be used to validate and monitor production to make sure that those items produced are manufactured to specification.

Finding the right vendor to supply your company with SPC software can be tricky. Not only do some vendors provide lesser quality than others, but it can also be difficult to decipher what exactly a vendor does provide with their SPC software without an SPC expert on-hand.

So, here are a few tips on how you can choose the right vendor for your needs:

As an experienced SPC vendor, Dimensional Control Systems has helped a large number of manufacturers explore and implement SPC tolls into their environment, even customizing those tools to better fit into the client's process. DCS is always happy to discuss your SPC initiatives and help you find the best solution for your organization.

These Stories on SPC

No Comments Yet

Let us know what you think