Experts in Tolerance Analysis Share Their Insight Into Handling Tough Tolerance Analysis Scenarios

Not every model is three pieces of sheet metal and a simple set of bolts. Some models pose a greater challenge than others, and these presenters and workshops combined to help users tackle those challenges.

Ensuring Conformance of Automotive Interior & Intuitive Controls with 3DCS

Sadiq Ali Basha G is a Deputy Manager for Comfort and Driving Assistance systems at Valeo India Private Limited, R&D center for the multinational automotive supplier Valeo, headquartered in Paris, France. Sadiq is also a Valeo certified Regional trainer for GD&T and Valeo Expert in the field of Mechanics. Sadiq has extensively used variation analysis software to conduct up-front

assembly build analyses to predict assembly variations and eliminate build issues.

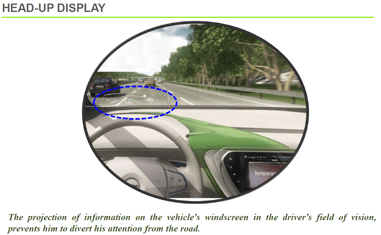

As such, he utilizes advanced techniques with tolerance analysis to control the performance of systems which would normally be considered unaffected by variation, or include many small components. In this case, the heads up display on the windshield of an automobile in addition to the steering column systems.

The Top Column Module (TCM) is the section of the steering column containing the control arms and mechanisms directly behind the steering wheel. Because of the amount of controls condensed into this device, there are a diverse number of directional switches, levers, ring rotators, rocker switchs and other interfaces to control the wipers, lights, cruise control and turn signals that have to function properly.

Image from http://www.valeo.com/en/top-column-modules-tcm/

The amount of space to place all of these devices in conjunction with the complexity makes variation a considerable influencer in final builds. Sadiq showcased how Valeo's established process simulated a variety of configurations to identify any that would not meet safety standards and optimize the contact surfaces to meet quality specifications. In doing so,

"All current requirements for contact safety of TCMs are simulated in 3DCS."

The Heads Up Display uses an imager projecting onto a reflector which puts the images onto the windshield of your vehicle. Because slight changes to the angle of either the projector or a reflector changes the location or distorts the image, the optical team wanted to make sure that the image would be within the best fit zone and at the optimal resolution without any pixel loss.

To do this, they incorporated the results from a tolerance analysis study and used these to;

"...gaurantee the beam projection by preventing pixel loss due to vignetting* of optical cone caused by variations." *Shading off

This is an excellent example of how variation from parts can influence other aspects of the product not normally considered to be a part of tolerance analysis.

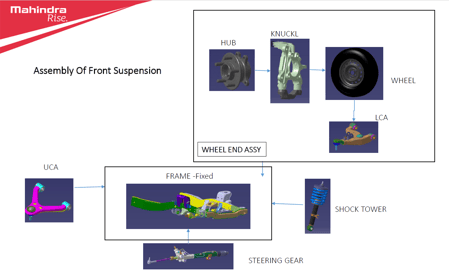

Effects of Dimensional Variations of Suspension Components on Vehicle Dynamics

Srinivasrao Balaga has more than ten years of experience in automotive design, with an expert level knowledge of GD&T (ASME Y-14.5M-1994/2007), CMM data analysis and root causing, as well as an expert in 3DCS software application in Drive Away Chasis systems. This experience has helped him become the certified Best Trainer at Mahindra Technical Academy for GD&T.

Utilizing this knowledge base, Srinivasrao demonstrated the effect of linkage tolerances on Vehicle Kinematic Behavior and how to best optimize the tolerances for better behavior. This is the best case for 3DCS application under normal circumstances, but because of the kinematic behavior of the linkages, Srivinvasrao used Mechanical Modeler in addition to the base 3DCS software.

Srinivasrao Balaga ran multi-position analyses on the camber, caster and toe of the assembly through the range of motion, plotting the variation and highlighting worst case to see if the bump steer gradient range was acceptable. As part of the process, his team used iterative design techniques to then optimize the design and check that the outputs were acceptable.

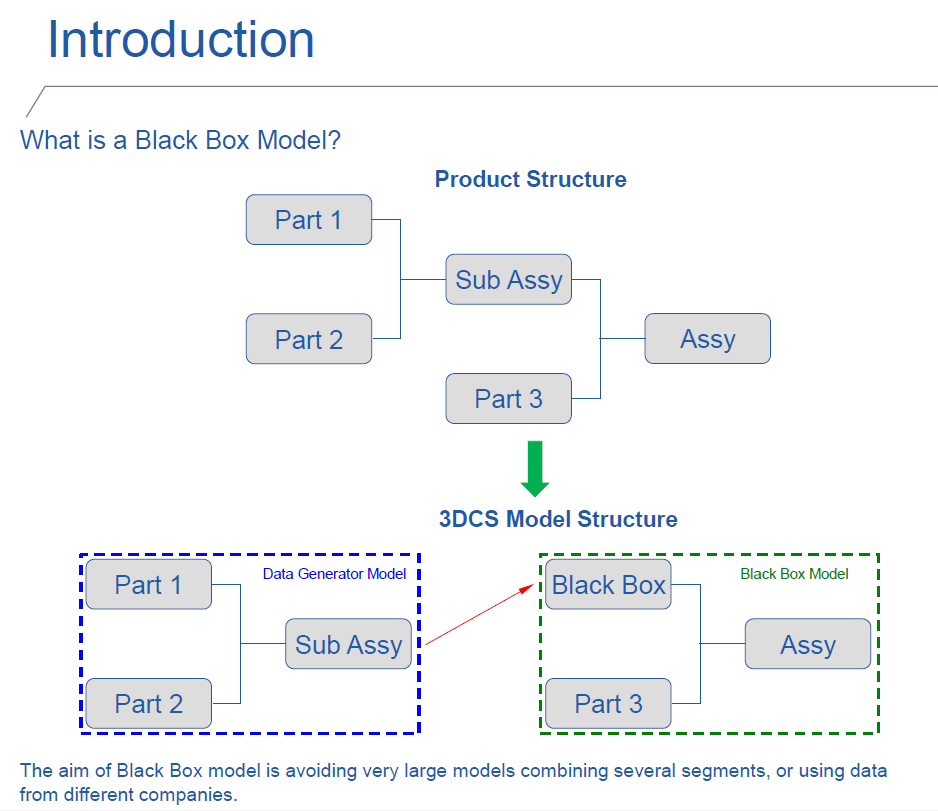

Working With Large Models - Black Box Methodology

Luiz Marcelo Ventorini, Mechanical Engineer, has been working as a Dimensional Engineer since 2006 in Product Development, performing Tolerance Analysis for several kinds of requirements (Aerodynamics, Stress, Systems and Manufacturing), GD&T applications and Interface Control Documents (with suppliers). He has also been working in the prototype and series phases activities such as product validation (metrology) and analyzing the difficulties faced on the assembly line.

As an aerospace engineer, Marcelo Ventorini often deals with extremely large models which can make analysis time consuming and slow. To speed up his analysis, Ventorini utilizes a technique called the 'Black Box Methodology'.

Black Box Methodology aims to turn sub-assemblies into single components when working in a model. By analyzing the sub-assembly first, the variation from that assembly can be applied to the overall assembly as a component in a larger structure, such as an aircraft.

This also helps when using data from suppliers, and in the case of 3DCS users, when using parts that may contain Compliant Components. Once the sub-assembly is black boxed, it contains the variation from its own analysis, but does not bog down your overall tolerance analysis simulation. This also removes the need to continually use Add-on module licenses when opening the model.

Advantages of Black Box:

- A big model with a lot of MTMs and a big stackup can be replaced by some points and tolerances;

- Only final results can be shared with other companies. Modeling strategy and process tolerances are hidden;

- Several Black Box Scenarios can be done based on only one model Data Generator Model run;

- Heavy FEA Compliant models can be replaced by a few points (also optimizing FEA licenses).

Disadvantages of Black Box:

- Depending on the result some curve fit must be done and some errors are generated;

- Some local datums must be created to measure the specific relationship between features;

- The original model is split, it’s necessary to manage two models;

- Some tricky higher order interaction, if not detected, can be lost;

- On the black box model, the sensitivity doesn't show the contributors (they are all bundled).

DCS Workshops - Modeling Efficiencies and FEA Compliant Modeler

With the morning over, the room was re-formed into two smaller rooms to conduct the training workshops. There were two workshops in total, and all attendees were able to attend one, then the other.

FEA Compliant Modeler

The FEA Compliant Modeler workshop used 3DCS FEA Compliant Modeler, the add-on module that brings finite element analysis (FEA) into your tolerance analysis to account for flexible and compliant parts. The workshop was aimed at new users, and designed to teach the skills to help 3DCS users expand their ability to include this kind of advanced analysis.

Modeling Efficiencies

This workshop went through a variety of tools, tips and strategies that can be used to make modeling faster, more efficient, and make updating the model later on a lot easier.

Make sure to check back in next week when we make the video recordings of the two workshops available.

A Final Walk in the City

As Thursday came to a close, it was clear that the majority of attendees were getting a little burned out. The conference kept everyone busy from morning to night, and with jet lag, and people trying to catch up on their own work in the after hours, the week was starting to catch up to everyone. Those who had friday travel plans and still wanted to see the city went out with DCS, using the People Mover, to see the city and enjoy a little of the downtown.

And All Good Things Must Come to an End

After the walk in the city, the event closed out. With 37 companies in attendance, 19 presentations, a half day of training, and evening networking events, the conference fulfilled its promise of keeping everyone busy and making sure that everyone had learned something to bring back with them.

No Comments Yet

Let us know what you think