DCS hosted their 3rd Global Technology and User Conference last week, bringing together engineers, managers and professionals from aerospace, medical device, automotive, consumer electronics and energy to share insights and experiences in the field of dimensional engineering and tolerance analysis.

The first day of the event began with a welcome lunch showcasing the view of the Detroit River and downtown Windsor. A sunny day, it was nice to begin the event on an easy note, having a meal and getting a chance to meet other attendees.

Guests and DCS Staff were able to meet before the event began.

A full Italian Style meal was offered, including Tiramisu and a Caprise Starter.

The view was fantastic, and with a beautiful sunny day, it was an excellent chance to get some sunshine and have a chat before or after lunch.

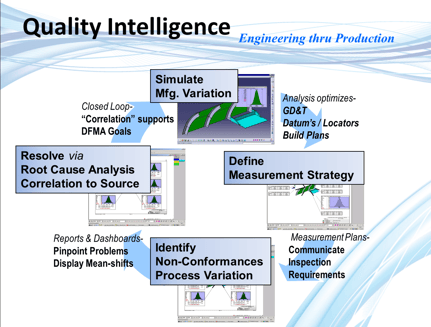

Don Jasurda, DCS VP of Sales, opened the conference with a Keynote discussion on Closing the Loop.

DCS began in the 90's as a service company working on dimensional engineering and promoting the Dimensional Engineering process. Most of you will recognize elements from this process in your own, as it incorporates many best practices and key elements seen in industry.

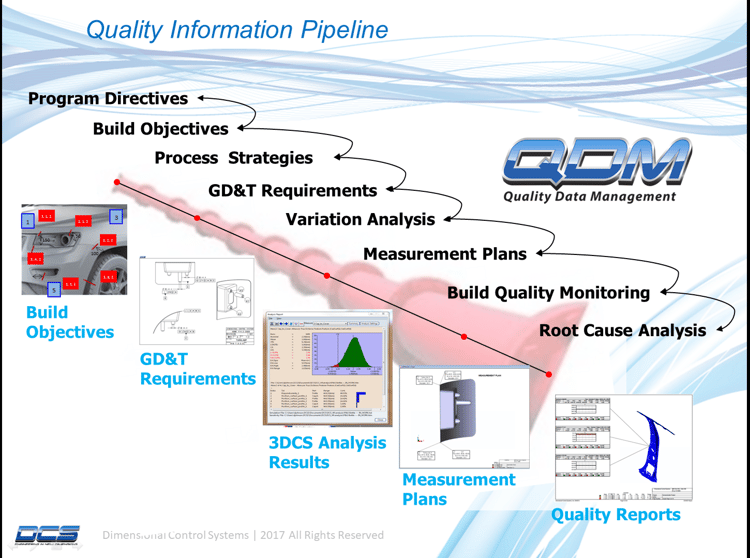

Donald Jasurda made note that DCS not only promotes this process as a component of PLM, but also supports it in ways most customers and companies are unaware of. With the inclusion of the QDM System in tandem with 3DCS Tolerance Analysis software, DCS is able to provide a quality solution that supports both design and engineering, as well as manufacturing and production. This process includes suppliers, engineers and designers as well as plant managers and quality professionals, giving real visibility across the enterprise.

Don Jasurda noted how QDM has grown to now include Cloud Deployment, which essentially allows any company to start using this SPC system without having to wait for setup. This makes QDM much more agile, giving companies the ability to use it with 3DCS to feed back plant data, or to push analysis, compliant documents (FAIR, Ppap) and data analysis results forward to share across the organization.

As DCS's tools continue to grow, so too do their connections to PLM and other elements in the process. With this in mind, companies have the ability to feed data forward, and backward, in the process, creating 'Closed Loops' that allow analysis of production data to root cause and resolve issues earlier in the product lifecycle.

Dave Johnson, 3DCS Product Manager, followed the keynote, highlighting the upcoming developments for 3DCS software and discussing some of the new features just released in version 7.4.

Just Some of the Advancements:

2017 has already been a big year for 3DCS and promises to deliver even more before it is over. Keep an eye on the DCS Newsletter and Community to learn about the latest advances, webinars and updates.

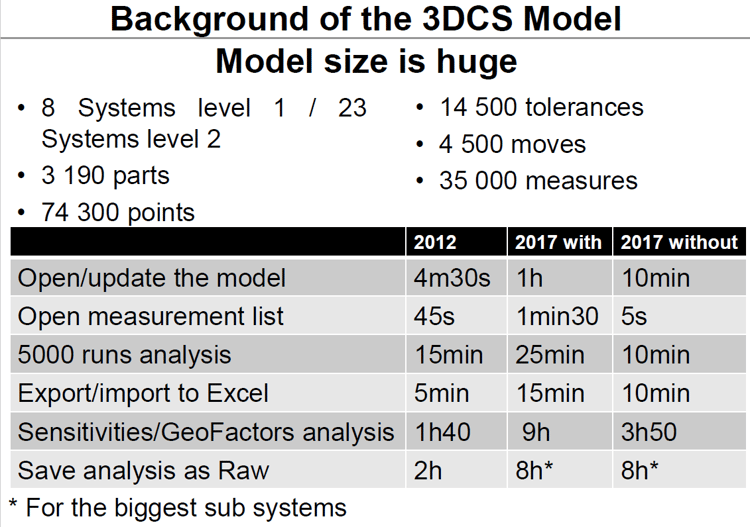

Pierric Leonard took the stage next, showing us how his team manages the ITER model, which has to be the largest 3DCS CAD model I've ever seen.

As Pierric Leonard put it,

"ITER ("The Way" in Latin) is one of the most ambitious energy projects in the world today.

In southern France, 35 nations are collaborating to build the world's largest tokamak, a magnetic fusion device that has been designed to prove the feasibility of fusion as a large-scale and carbon-free source of energy based on the same principle that powers our Sun and stars."

Here is a short video from the ITER Organization to give you an idea of what they are attempting to do:

The model itself is massive, with 14,500 different tolerances and 35,000 measures.

It was once remarked to me that the ITER Tokamak is like a Swiss Watch, only the size of six football fields!

Pierric Leonards presentation was a great example of methods used to manage such large amounts of data, and of methods of reducing simulation and interaction times.

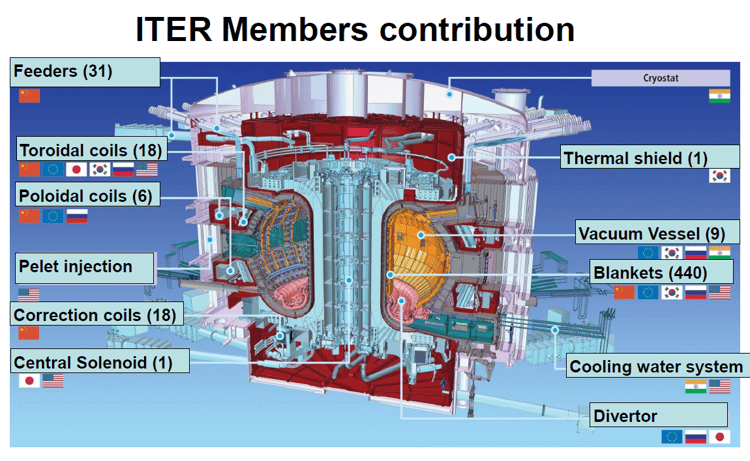

Before we move on to the next presenter, I'd like to point out the global reach of the ITER project. As Leonard mentioned, 35 nations contribute to the ITER project, and this illustration does a great job conveying just how difficult the logistics of this project must be.

With major components coming from a group of different countries, it is important that they fit together at final assembly. With 3DCS, the team is working hard to make that a reality, and it is truly an impressive feat.

Earl Morgan and Brenda Quinlan, both Senior Variation Analysts at DCS, presented the latest in analysis. This new method, Simulation Based Sensitivity, gives users the ability to run Sensitivity analyses using Monte Carlo based simulation data. This gives more in-depth results, and can give more accurate results in complex scenarios such as in non-linear models.

Simulation Based Sensitivity is the next stage in the advancement of 3DCS analysis. We can now see into 3DCS model behavior in ways not possible before. Besides the usual HLM lists, we now gain insight into multivariate interactions between inputs and their effects on output mean shift. Designed experiments gain a high level of accuracy and speed because of Simulation Based regression. Simulation Based Sensitivity presents all this rich information to the user in several different viewing flavors - variance, mean shift, geometric coefficients, and more.

Continuing the discussion introduced in the Keynote address, Gary Bell, DCS Senior Variation Analyst, demonstrated how to use 3DCS as a manufacturing tool for root cause analysis. This essentially 'Closes the Loop' by bringing measurement data into 3DCS allowing the analysis of actual as-built information instead of simulated information.

To make this process easier, 3DCS and QDM can be used to create correlated measurement plans, which bring your manufacturing and suppliers into the information loop.

This can be pivotal in determining the true culprit in manufacturing problems, as well as being able to determine and incorporate mean shifts that occur in manufacturing but were not put into the initial simulation.

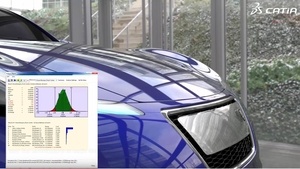

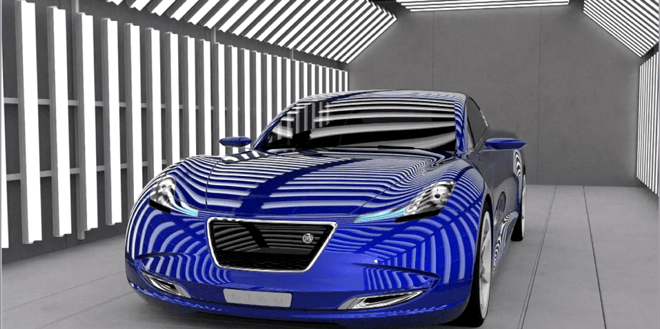

Closing out the day, Gerard Alcini, CATIA Technical Sales, Shape and Styling, showcased the way 3DCS connects with Dassault Systemes CATIA V5 and the 3DEXPERIENCE (build on CATIA V6) to deliver photo realistic product images incorporating manufacturing process and part tolerances.

This gives a 'real' version of the product, rather than just nominal, and lets designers, engineers and quality professionals determine how given tolerances can impact the appearance of their final product.

Given tolerances can be acceptable for manufacturing, allowing the parts to be assembled more easily or produced more cheaply, but this does not take into account how the product will look. Just like meals, where appearance may have a major impact on taste and flavor, so too in products does the appearance influence the customer experience. A product that is created and sold as a high quality product needs to have an appearance to match.

With this collaborative environment, manufacturers have the power and ability to find out just how their products will look before using expensive prototypes or clays.

In addition to this, Dassault Systemes brought their Heads Up Display, a head set that allows users to see their product in three dimensions. You can get under the car and see the exhaust system, or open the doors and check closures. What's more, the system allows the user to lean in and view internal components, like the gas tank or the engine under the hood. This truly innovative technology incorporates 3DCS data so that the gaps, flushes and variation from your models can be accurately portrayed on your product, letting you see it from different angles and in different lighting conditions.

The first day, which was only a half day, included a lot of new innovation and ideas. With partners like FARO Technologies showcasing their tools, Parallel Works with their Cloud based processing power, and Dassault Systemes showcasing visualization and tolerance analysis together, attendees were able to get a hands on experience with the latest technology.

The day finally ended with a visit to Granite City for dinner and discussion of the days events.

Looking for presentations, videos and pictures from the conference?

Contact DCS Directly to get Access

Looking for Day 2 - Industry Successes with Tolerance Analysis

Looking for Day 3 - Tackling Tough Tolerance Analysis Scenarios

These Stories on CATIA

No Comments Yet

Let us know what you think