See it yourself -->

Metrology plays a crucial role in industrial processes as it involves the measurement and analysis of various parameters to ensure accuracy and quality.

Accurate measurements are essential in manufacturing processes to ensure that products meet the required specifications and standards.

Metrology helps in improving the efficiency and productivity of industrial processes by identifying and correcting any deviations or errors.

It enables manufacturers to monitor and control the quality of their products, leading to customer satisfaction and trust in the brand.

In industries such as automotive, aerospace, and medical devices, metrology is especially important as precision and accuracy are critical.

Overall, metrology is a fundamental aspect of modern industrial processes, ensuring the reliability and performance of products.

Sandvik Manufacturing Solutions (SMF) offers an innovative metrology solution that revolutionizes the measurement and inspection processes in various industries.

Their metrology solution combines state-of-the-art technology with advanced software to provide accurate and reliable measurements.

Sandvik's solution includes a range of high-precision instruments and equipment that are designed to meet the specific needs of different industries.

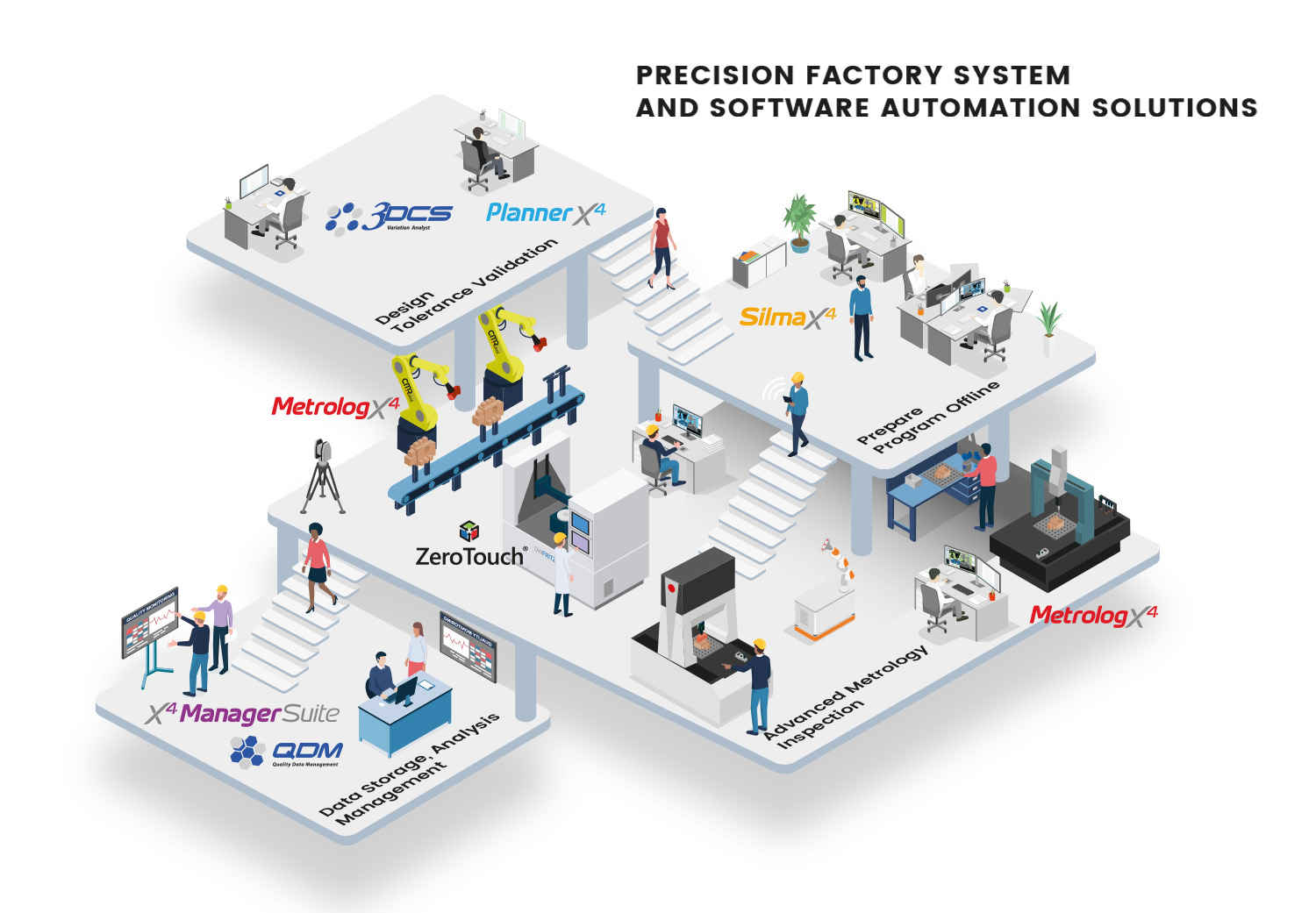

This solution brings together the technology of multiple organizations into a powerful metrology and production quality solution. Metrologic, Dimensional Control Systems, and DWFritz all contribute technology and equipment to the Sandvik solution.

This solution brings together the technology of multiple organizations into a powerful metrology and production quality solution. Metrologic, Dimensional Control Systems, and DWFritz all contribute technology and equipment to the Sandvik solution.

With Sandvik's metrology solution, manufacturers can enhance their quality control processes and ensure compliance with industry standards.

The solution is user-friendly and provides real-time data analysis, allowing for immediate feedback and corrective actions.

Sandvik's metrology solution is a game-changer in the field, offering advanced capabilities and unmatched accuracy.

The Sandvik metrology solution offers several key features and benefits that make it stand out from competitors:

1. High Accuracy: The solution provides precise measurements with minimal errors, ensuring product quality and reliability.

2. Versatility: Sandvik's metrology solution can be used in various industries and applications, and with any measurement device, catering to different measurement needs.

3. Efficiency: The solution streamlines the measurement process, saving time and reducing costs for manufacturers.

4. Data Analysis: Sandvik's metrology solution includes advanced software for data analysis, allowing for in-depth insights and process optimization.

5. Real-time Monitoring: Manufacturers can monitor the measurement process in real-time, both on the shop floor and via web dashboards, ensuring immediate detection and correction of any issues.

6. Industry Compliance: The solution meets and supports industry standards and regulations (PPAP, FAIR, APQP...), ensuring that manufacturers can confidently meet customer requirements.

By leveraging these features and benefits, manufacturers can significantly improve their measurement and inspection processes.

Led by Metrologic, Sandvik's innovative metrology solution is being showcased at the Control Messe Show in Stuttgart, Germany.

The Control Messe Show is one of the leading trade fairs for quality assurance and metrology technology.

Sandvik's presence at the show highlights their commitment to advancing metrology technology and providing cutting-edge solutions to industries.

Sandvik's presence at the show highlights their commitment to advancing metrology technology and providing cutting-edge solutions to industries.

Visitors to the show can explore Sandvik's metrology solution firsthand and learn about its features, benefits, and applications.

Sandvik experts will be available to provide demonstrations, answer questions, and discuss how the solution can benefit different industries.

The company's participation in the Control Messe Show reinforces their position as a leader in the metrology industry.

The future of metrology technology looks promising, with continuous advancements and innovations on the horizon.

Manufacturers can expect further improvements in accuracy, speed, and ease of use in metrology solutions.

Advanced technologies such as artificial intelligence and machine learning will play a significant role in enhancing metrology capabilities.

Automation and robotics will further streamline the measurement and inspection processes, increasing efficiency and productivity.

Integration with other digital systems and platforms will enable seamless data exchange and analysis, leading to better decision-making.

Integration with other digital systems and platforms will enable seamless data exchange and analysis, leading to better decision-making.

Overall, the future of metrology technology holds immense potential for revolutionizing industrial processes and driving quality improvements.

Sandvik is at the forefront of these developments, continuously investing in research and development to bring the latest innovations to the market.

See the show yourself - Join our webinar to meet the team and learn about the solution from the show floor -->

These Stories on CATIA

No Comments Yet

Let us know what you think