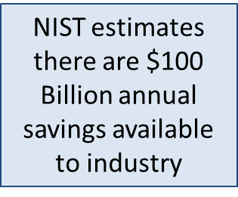

The Quality Information Framework (QIF) standard was used to facilitate a Model-Based Definition (MBD) pilot at a Tier 1 Manufacturer. The pilot specifically addressed the 3D data interoperability gap that exists when 3D data is passed from an Original Equipment Manufacturer (OEM) to a supplier. QIF v3.0 is an American National Standard that provides a common interface for digital interoperability that maintains the digital thread (3D data traceability) and enables closed loop feedback throughout product manufacturing. For example, it captures measurement results in the product model adjacent to the design requirement (i.e., tolerance).

QIF defines, constrains, and provides for the exchange of MBD, quality planning, measurement results, and enterprise connectivity via a persistent unique identification method called the QIF Persistent Identifier (QPId). QPIds are universally unique identifiers (UUIDs). The use of QIF and QPIds allows for the digital capture of the design requirements and measurement results without manual data entry. The techniques and tools used in this pilot resulted in reduced lead time, increased data reporting accuracy, and improved OEM-to-supplier collaboration.

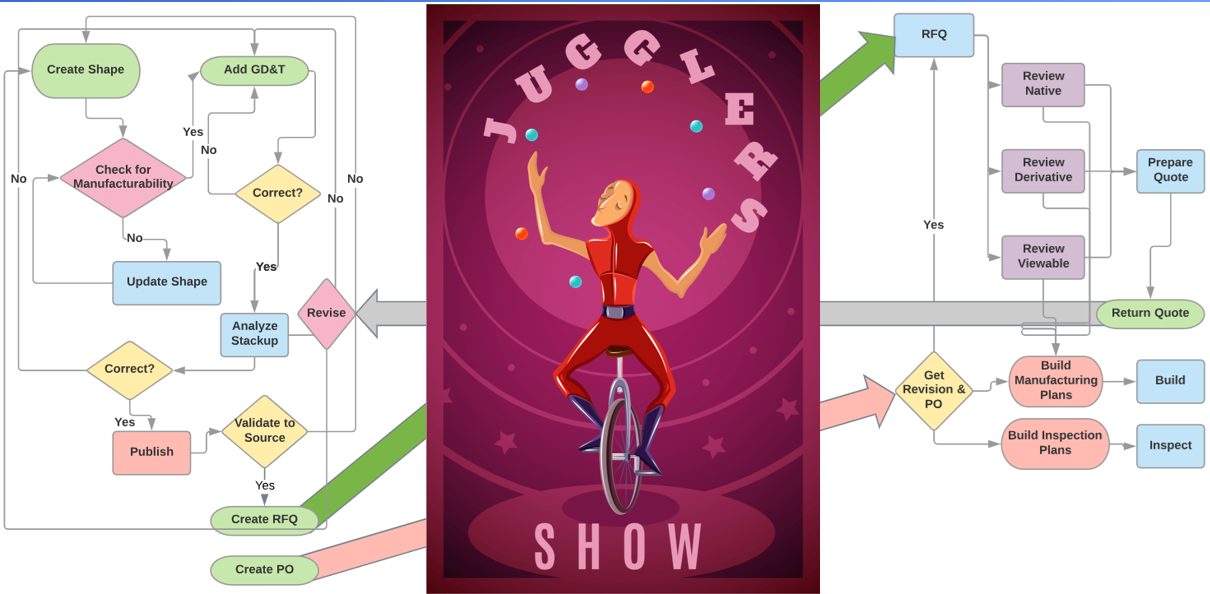

Figure 1: Today, passing data from the OEM to Supplier is a complex workflow of human checking to ensure data integrity. The reason for this is due to the 2D nature of drawing-based documentation methods. Uncertainty and suspicion in the accuracy of this static data drives some industries to spend millions of dollars each year on intensive, error-prone data exchange. [2]

Passing 3D model data without a drawing from an Original Equipment Manufacturer (OEM) to a supplier generally creates interoperability chaos. This chaos inhibits the opportunities available in manufacturing today. NIST estimates there are $100 Billion annual savings available to industry if we [1]:

Because the manufacturing industry relies so heavily on static documentation methods (e.g. drawings) that are not machine-readable, the industry cannot leverage the $100 Billion annual opportunity.

Because the manufacturing industry relies so heavily on static documentation methods (e.g. drawings) that are not machine-readable, the industry cannot leverage the $100 Billion annual opportunity.

To date, native and derivative solutions have been employed, but lack automated data traceability. Today’s methods rely on manual human analysis to compare design requirements against actual measurements (e.g. copy a table of data from Excel® into another table in another document to capture measurements).

Because manufacturers and especially suppliers are caught up in the way they have always done business, they are not able to see a new method. The pilot conducted at the Tier 1 Manufacturer and their Tier 2 Supplier successfully tested methods that move beyond the status quo.

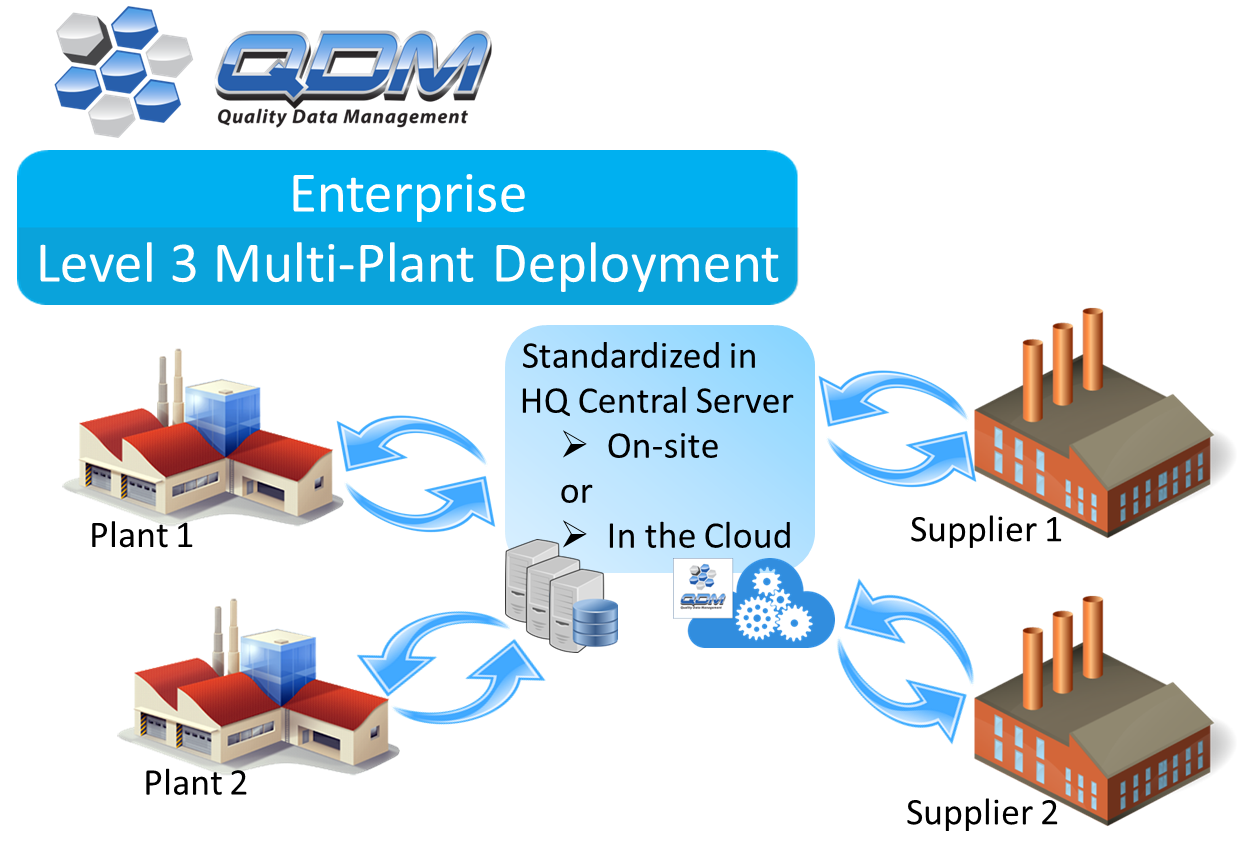

The problem is not that manufacturers and suppliers do not have the tools and knowledge necessary to implement Model-Based Definition (MBD). The problem is that each of these companies has likely created their own standards and methods for how information is disseminated throughout their ecosystem. This includes both the machine-readable and human-interpretable information. While introducing a new language that offers so much potential savings by enabling advanced manufacturing capabilities, it does require a framework of standards and methods to ensure that data being transferred across the enterprise, including the supply chain, retains its authority and integrity. This also ensures that everyone in this ecosystem will be able to benefit from

this new language.

Learn more about how QIF has been leveraged to connect manufacturers and suppliers...

[1] - Thomas Hedberg 2017 GPDIS Presentation https://gpdisonline.com/wp-content/uploads/2017/09/NISTThomasHedberg-

EngineeringA100bParadigmShift-Keynote-Open.pdf

[2] - Jennifer Herron 2017 MBE Summit Presentation https://www.nist.gov/sites/default/files/documents/2017/04/18/07_herron_mbe17-040-

mbd_supplier_readiness.pdf

These Stories on CATIA

No Comments Yet

Let us know what you think