Quality data management systems provide this optimization by increasing efficiency, speeding up the quality management process, and eliminating scrap, rework, warranty claims and non-conformance.

Traditionally, suppliers use a variety of tools to measure parts, and they provide that data in various formats that may or may not be cross-compatible. Compiling discordant data takes time, and gleaning statistical process control from disparate sources can be relatively impossible.

Trudging through varying data sets from your list of suppliers can leave you with incomplete information about upcoming issues and possible risks.

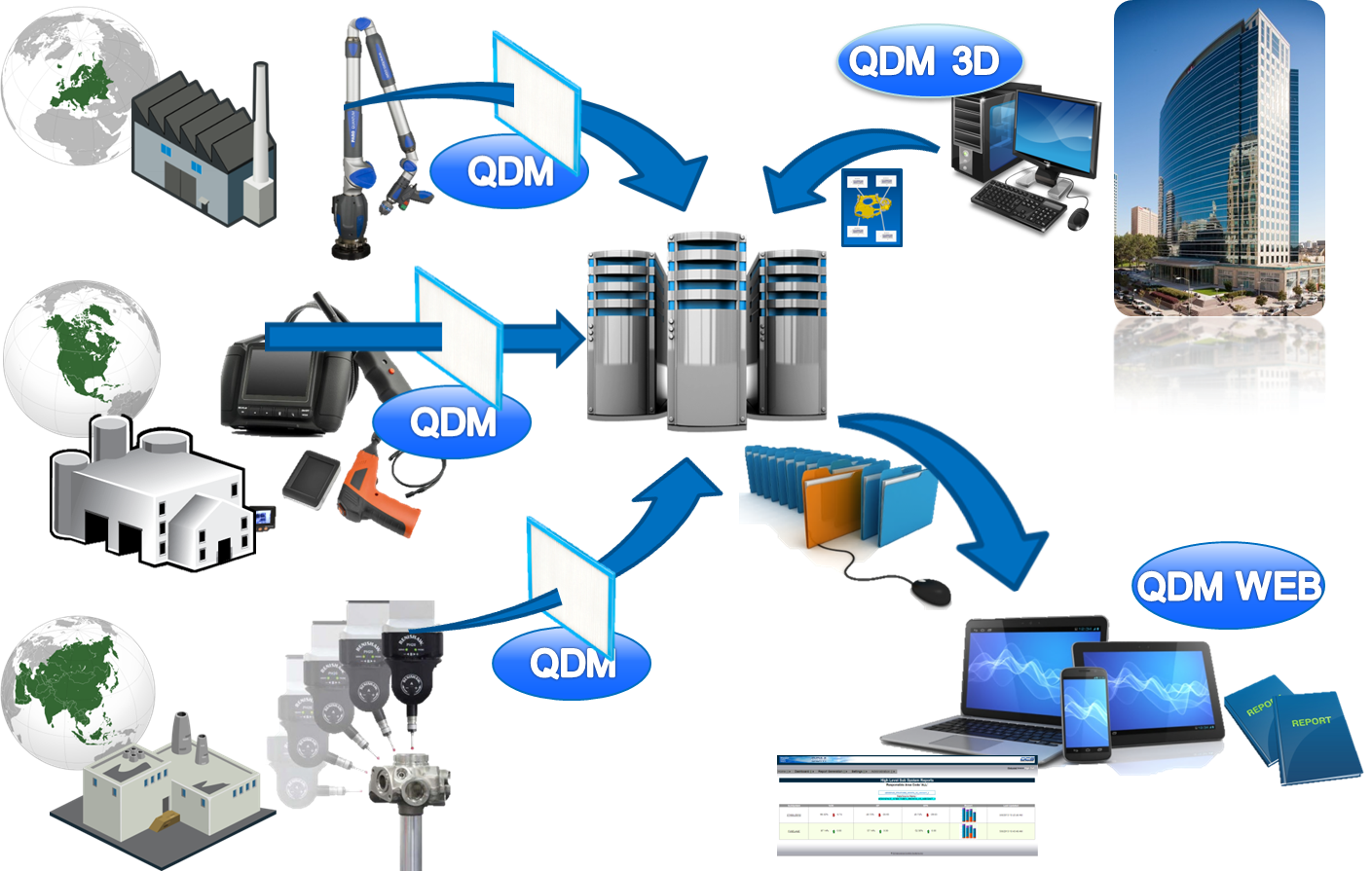

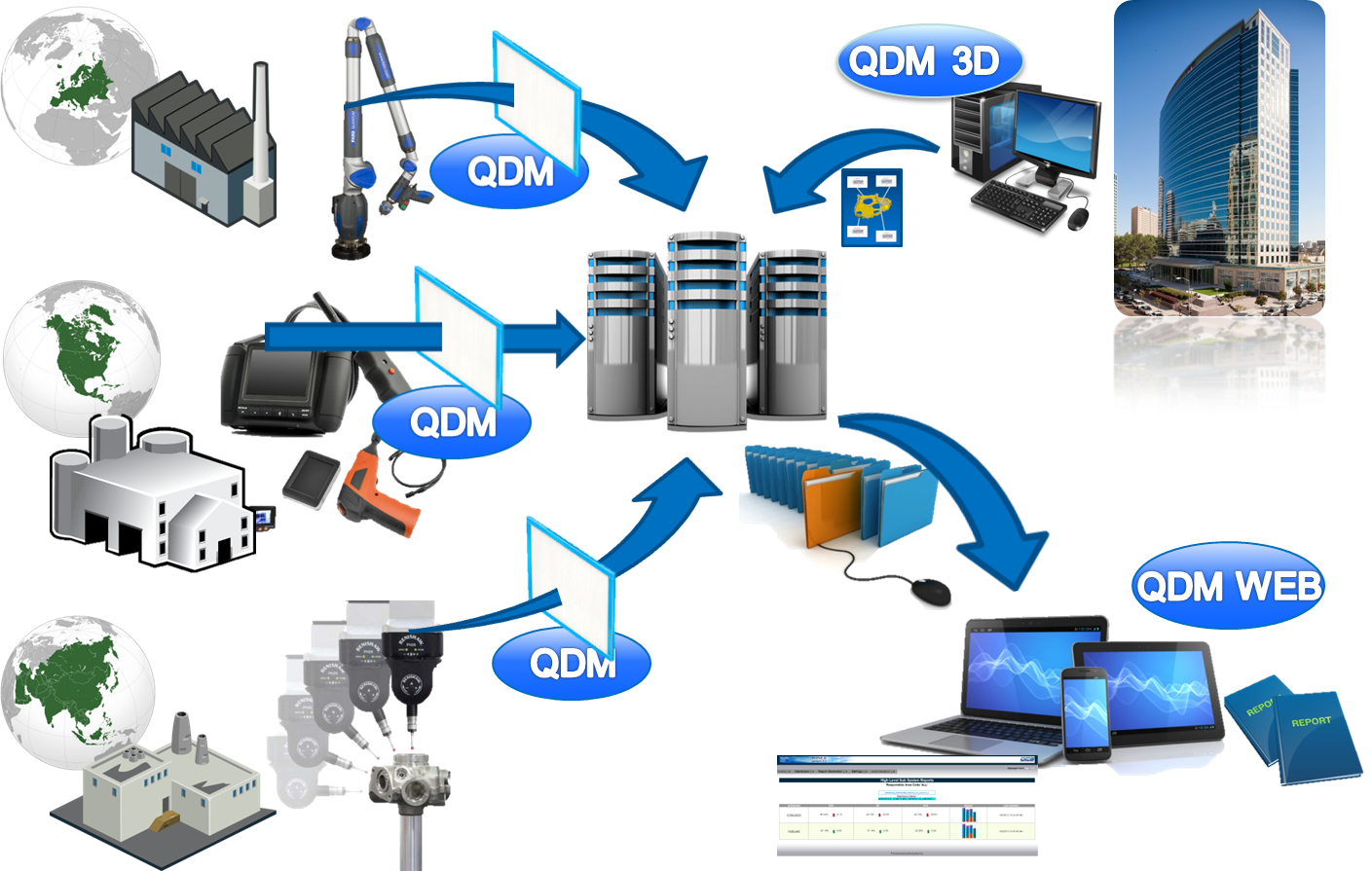

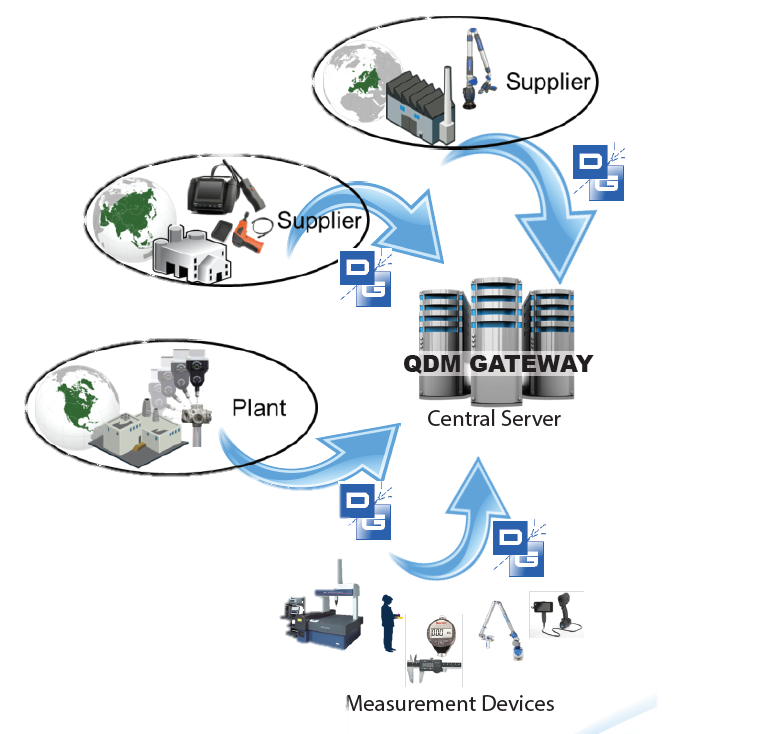

With a connected, collaborative system you can bridge the supplier to OEM gap by collecting measurement plans and quality information from all suppliers and producing a cohesive, actionable report.

With a quality data management system, your suppliers can upload their data to a centralized and standardized template. This template allows you to quickly identify parts that pass or fail, and clearly communicate quality requirements back to all suppliers.

Data can be instantly validated by embedded pass/fail criteria, and the reports produced provide all the information you need to make immediate, actionable decisions.

Supply chain standardization allows you to recapture lost time, benefit from real-time production quality monitoring, customize reports, collate data from multiple suppliers and automate quality processes.

With a quality data management system, you get the standardization you need to reduce costs, streamline manufacturing and ultimately improve product quality. Set it and forget it with a quality data management system that puts you in ultimate control of your supply chain.

Original equipment operators deal with many different suppliers and products, and not everyone follows the same measurements and procedures. When the supply chain isn't standardized, it leads to waste and other issues that quickly weigh down a business.

It's only through standardized processes and measurements that you can fully control the supply chain and reap the benefits.

When you're dealing with one supplier who uses a specific tool for measurement and another that uses a different tool and yet another that uses a completely different measurement, things can get confused quickly.

You don't want to lose money because the wrong size went to the wrong client, so let a QDM system help. It's a connected, collaborative system that allows for standardization and easy communication between the OEM and the Supplier.

You can collect and share information without worrying about missed signals in an easily understandable format.

Imagine being able to take measurements and inspection data and send it to a centralized system to identify critical quality features and create easy to read reports. It also goes into a dashboard with quality metrics, email alerts and support.

It supports everything from the engineering level to production. You can define strategy, identify non-conformances process variation and resolve them through root cause analysis.

When you're able to consolidate inspection data, you create a standardized database and can generate reports on demand. You'll watch efficiencies increase. You'll be able to query dataset using specific criteria and drill to the root cause of issues graphically.

It's a solution that will save you money and is scale-able. No more suppliers sending varying formats or unclear quality requirements. It's clear and simple communication. There's no more time-consuming analysis because the pass/fail criteria are embedded into the template.

These Stories on CATIA

No Comments Yet

Let us know what you think