It is all too common in the industry: a part design is created and sent out for production only to hit repeated snags as questions arise about symbols or values. Even simple misunderstandings, such as where the Geometric Dimensioning and Tolerancing (GD&T) lines terminate, have resulted in serious delays (in some cases, of more than a month) and non-conformance issues, which resulted in wasted products.[1]

Companies that still utilize 2D drawings in their product life cycle are doing more than simply ignoring the increased productivity that comes from the streamlining of their models. They are also failing to provide their customers the best, most cost-efficient products and services that can only come from implementing a single comprehensive digital model that all stakeholders can effectively utilize. Moving away from 2D renderings (or even a hybrid approach with a 2D original and 3D model) to a completely digital design solution offers a wide range of benefits. Companies that incorporate digital GD&T with model-based definition (MBD) 3D models can create more accurate representations that speed up the design and production processes, reduce waste and improve communication and collaboration across all teams involved in the design and manufacturing process.

Originally birthed in the aerospace industry because of the critical need for tight tolerances, increasing numbers of manufacturers are turning to MBD for their design requirements. MBD, also sometimes referred to as the "digital product definition," allows for the migration from 2D paper-based drawings to comprehensive 3D CAD models. The models created via MBD include all of the necessary information required to generate the part so no other files or drawings are needed. This reduces the need for an extensive collection of additional paper files or backups.

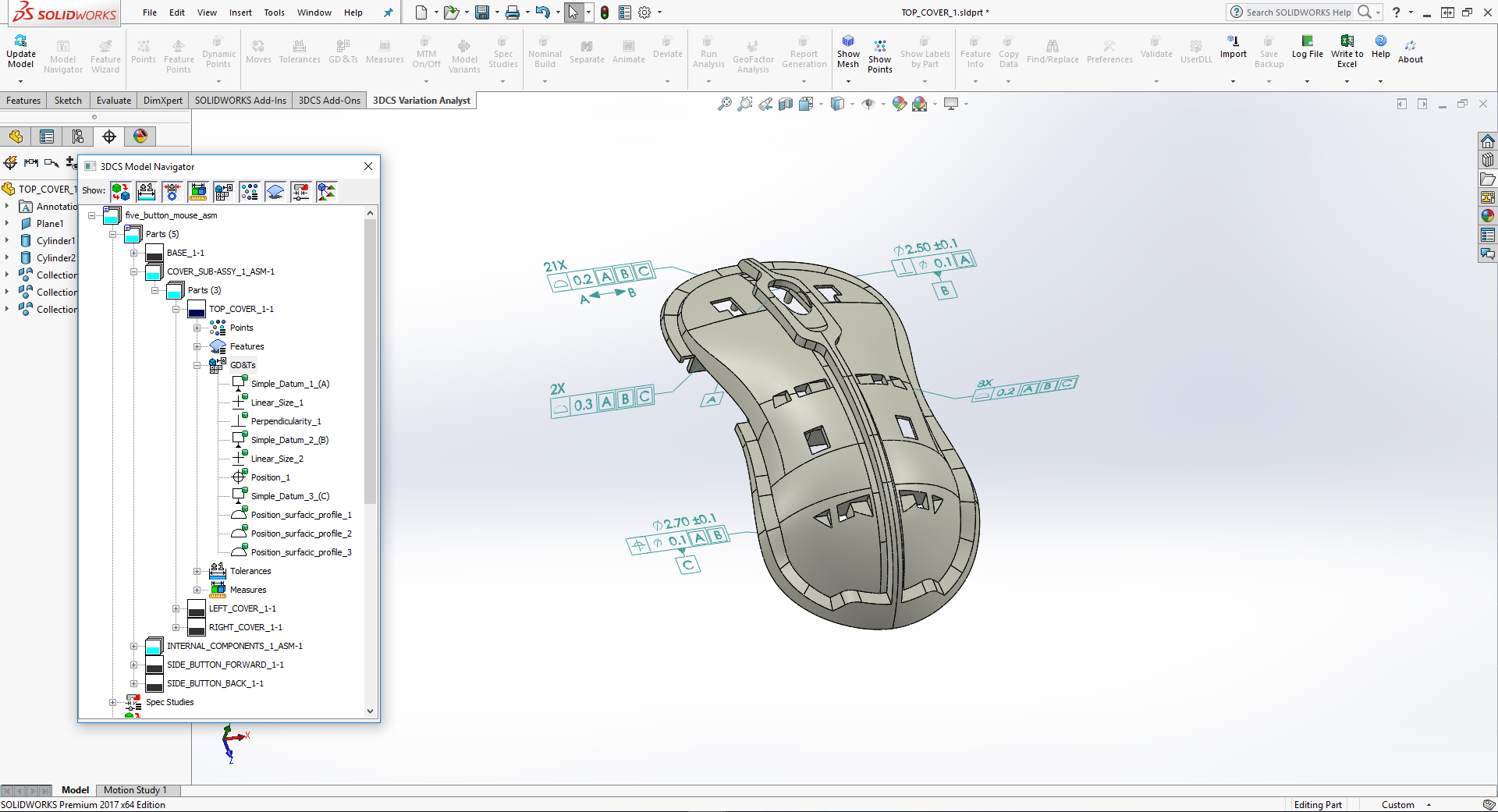

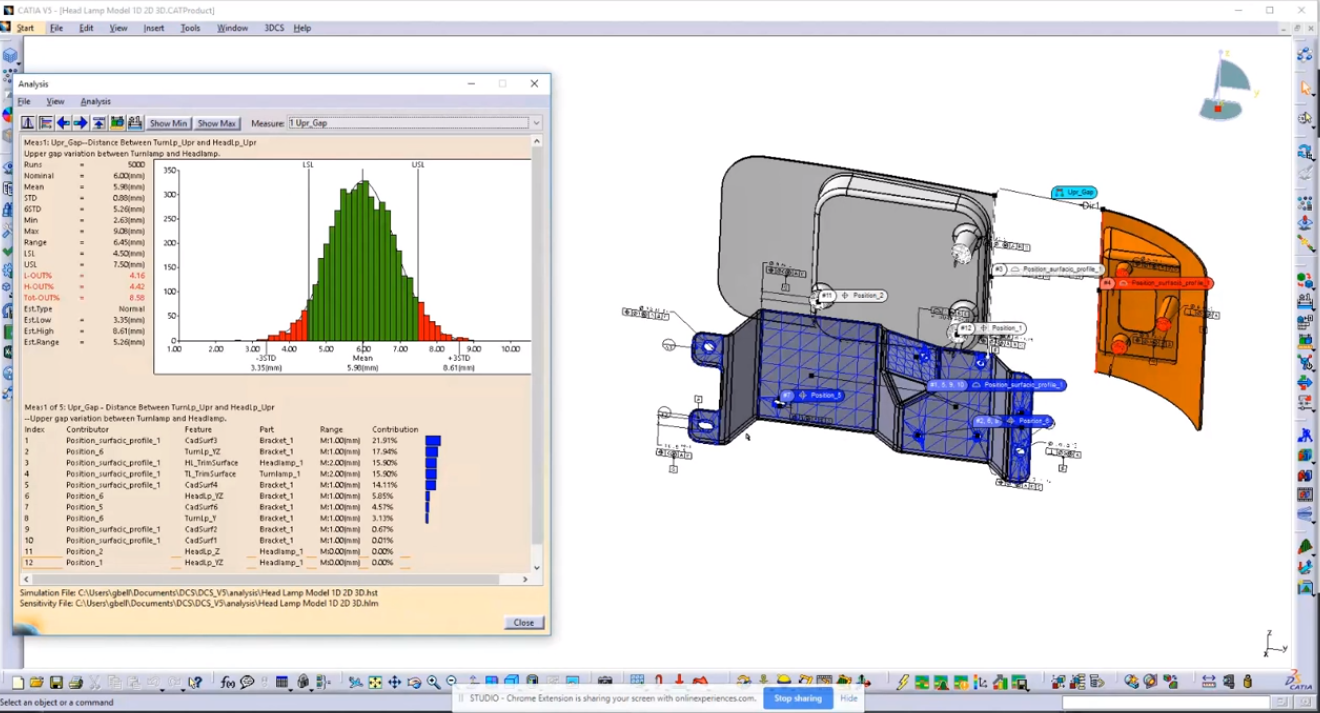

MBD is about streamlining the design and manufacturing process. It also results in parts that integrate into their target systems in a more seamless fashion, resulting in better outcomes and less waste. Importantly, MBD, which is based on the 2003 ASME Standard Y14.41-2003 Digital Product Definition Data Practices, allows designers to directly include GD&T data in the 3D CAD model.[2,3] MBD offers a broad range of benefits. It reduces the amount of manually reproduced data (as well as the errors inherent in that process) and diminishes the number of errors in a design. MBD also improves communication between designers and other stakeholders and boosts response times.[4]

Although GD&T and MBD have sometimes been confused, GD&T actually sits under the umbrella of MBD. GD&T, based on ASME Y14.5M-1994[5] and ISO 16792 3D,[6] is a concise language system that defines and identifies the features and attributes of a part. It forces designers to think about the functionality of a part in light of its final product.[7] Digital GD&T is the incorporation of that system in a virtual environment, such as CAD. It is an essential part of MBD and promotes its use by making the artifact more user-friendly to stakeholders who have limited understanding of the system. For example, tolerances are more clearly defined in a 3D model than on paper.[8]

Using only one 3D model with all the data necessary means that the model is the master. Since stakeholders all have access to the same model, better collaboration is possible. The MBD model eliminates redundancies throughout the design and manufacturing process and allows for the reuse of model definition data in downstream applications. MBD also improves a company's ability to inspect and report part quality across the supply chain. It helps to improve the quality of both designs and finished products, reduce the time to market and boost the communication between the various stakeholders involved in the manufacturing process, such as the designers and suppliers.

A number of large companies already utilize MBD to support corporate, design and manufacturing objectives, such as Boeing (one of MBD's early adopters), Raytheon Missile Systems Company, General Motors, and Caterpillar.[9] MBD promotes quality throughout the design and manufacturing process via standardization and limited human-driven modification. Since MBD is scalable, it can be used for everything, from model-based engineering and manufacturing to the complete product lifecycle management.[10] At its heart, digital GD&T best serves MBD by making the tolerances of the figure more understandable and universally understood.

Article Sources:

1)https://www.nist.gov/sites/default/files/documents/2017/04/18/05_cost_benefits_in_mbe_v2.pdf

2) https://www.asme.org/engineering-topics/articles/design/digital-tolerance

3) http://www.etinews.com/pdf.files/Y1441presentation.pdf

4) MBD Whitepaper

5) https://www.asme.org/products/codes-standards/y1451m-1994-mathematical-definition-dimensioning

6) https://www.iso.org/obp/ui/#iso:std:iso:16792:ed-2:v1:en

7) http://www.etinews.com/gdt_glossary.html

8) http://blogs.solidworks.com/solidworksblog/2017/11/model-based-definition-beyond-3d-drawings.html

9)http://digital.bnpmedia.com/publication/?i=127178&article_id=1182926&view=articleBrowser&ver=html5#{%22issue_10) https://www.qualitymag.com/articles/94579-model-based-definition-puts-gdt-data-to-work

11) 2016 Conference Whitepaper

12) https://internetofthingsagenda.techtarget.com/definition/Industrial-Internet-of-Things-IIoT

13) http://www.industryweek.com/systems-integration/demystifying-digital-thread-and-digital-twin-concepts

14) https://searcherp.techtarget.com/definition/digital-thread

15) http://blog.3dcs.com/proactively-control-quality-with-the-digital-twin

16) http://www.industryweek.com/systems-integration/demystifying-digital-thread-and-digital-twin-concepts

17) http://computingengineering.asmedigitalcollection.asme.org/article.aspx?articleid=2492076

These Stories on CATIA

No Comments Yet

Let us know what you think