Having a system to standardize communication between suppliers and OEM's

A key component of superior quality management is the standardization of measurement processes from OEM to suppliers via Statistical Process Control (SPC) methods. Often, quality requirements and reporting outputs are defined by the supplier, which means data may come through in various formats.

It takes too much time to build reports from raw data outputs - why waste your engineers and quality teams time?

It takes too much time to build reports from raw data outputs - why waste your engineers and quality teams time?

The data then may need translation and must be manually entered into reports and then analyzed for decision making. This process can be incredibly time-consuming when having to accommodate the inconsistent data collection formats, while also leaving room for human error, finally resulting in undue scrap and rework costs. Does this sound familiar?

Without a system in place, you could be making defective products without knowing it

Without a system in place, you could be making defective products without knowing it

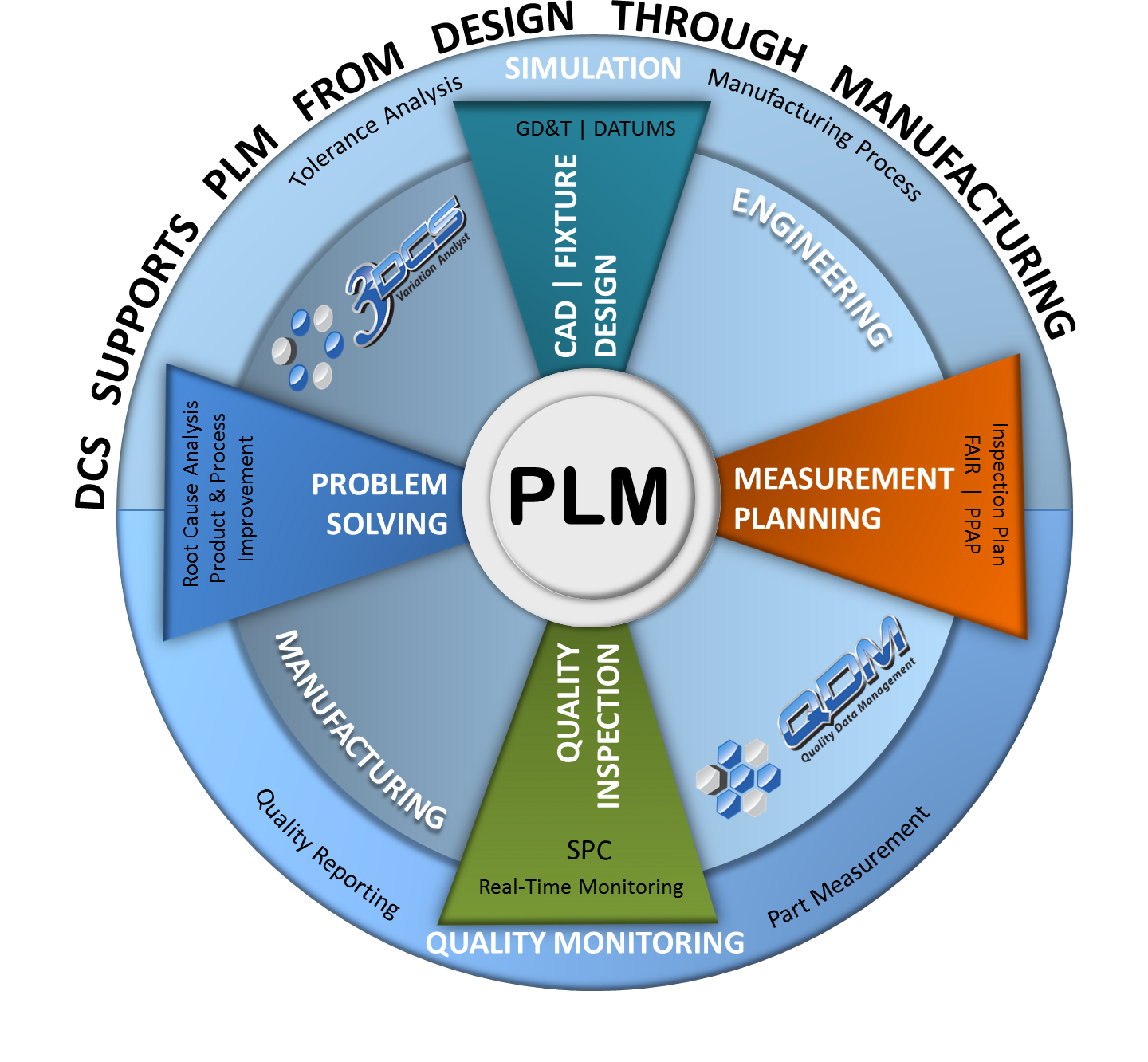

Quality metrics can be greatly improved through the implementation of a connected, collaborative system to share and collect quality information. The world leader in dimensional engineering and quality data management, Dimensional Control Systems (DCS), has introduced customizable quality solutions that utilize a closed-loop approach.

Closed Loop systems connect the digital thread, using the CAD model as a sole source of information and allowing for fast notification of issues and powerful root cause analysis

Closed Loop systems connect the digital thread, using the CAD model as a sole source of information and allowing for fast notification of issues and powerful root cause analysis

DCS Quality Solutions effectively improve efficiency and reduce costs across the enterprise by extending quality management far beyond the manufacturing environment as a complete system that encompasses Product Lifecycle Management (PLM) entirely.

QDM technology is a fully customizable, economical and scalable software suite that enables organizations to report, analyze and share all types of quality inspection data through a standardized format that is easy to interpret.

Some benefits to a system of this type include:

To learn more about how DCS Quality Solutions can benefit your organization, a comprehensive overview of the QDM SPC System can be found here. A video presentation titled Bridge the Supplier to OEM Gap is also available.

Don't miss the June Webinar showcasing a Case Study of Supplier Quality connection using QIF files

These Stories on CATIA

No Comments Yet

Let us know what you think