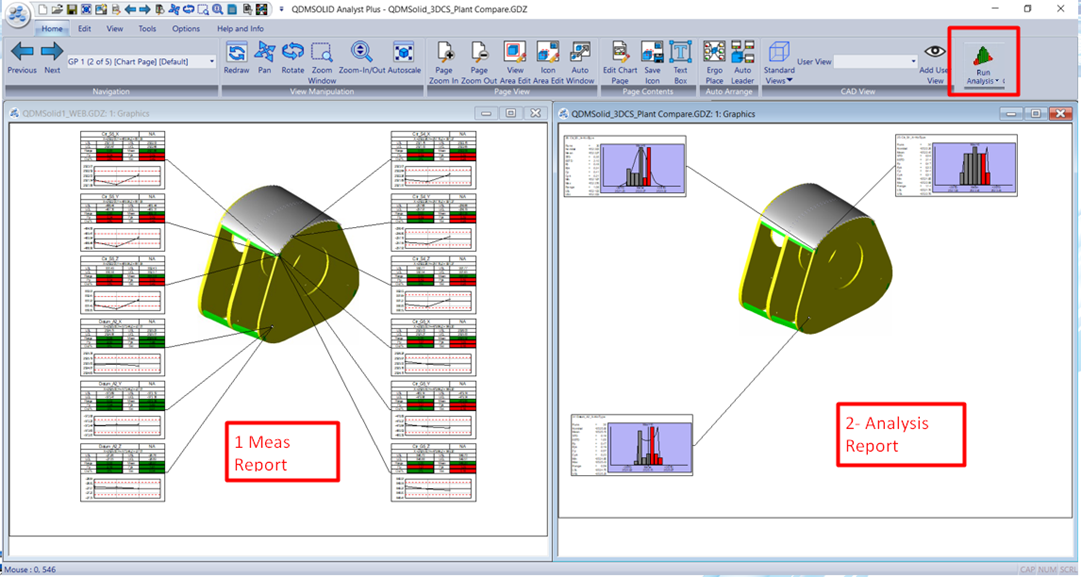

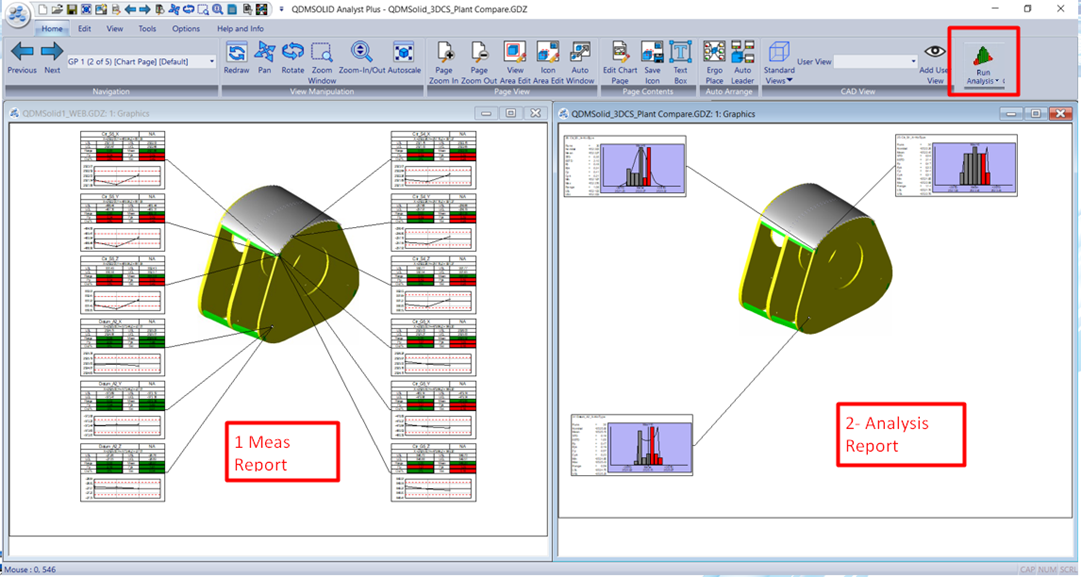

A Virtual Build is a CAD model that represents the physical product using measurement data. This Virtual Build allows simulation, design optimization, and root cause analysis of production as a replacement for the nominal and predicted designs.

A Virtual Build is just that; building a product virtually. It does not contain all the connections and information of a Digital Twin, but can be a powerful driver of Digital Twins and Digital Transformation. The Virtual Build focuses on the CAD model and its representation of dimensions related to the actual manufactured product. This incorporates all of the measurement data as well as Product Manufacturing Information and GD&T (if available), allowing simulation to use the dimensions of actual products instead of nominal design.

The Virtual Build allows the use of GD&T to drive design and measurement planning, which in turn connects and correlates as-built data in manufacturing. The feedback loop of inspection back into CAD unlocks all of your simulation, Finite Element Analysis, and digital testing tools to use in continuous quality improvement and production problem-solving.

Quality 4.0's greatest value is the automation of systems. Connecting different systems manually often entails exporting files and importing them into different programs, which can lead to errors, corrupted files, import issues, and the need to repair the files after import. Automating these connections with Quality 4.0 creates a streamlined approach that improves efficiency and reduces errors.

In this webinar, learn how to automate the use of measurement data in 3DCS Variation Analyst to run tests, simulations, analyses, and root-cause analyses on your manufacturing quality. Utilize your CAD points with your CMM to easily correlate the data and unlock the power of 3DCS software for your as-built products.

These Stories on CATIA

No Comments Yet

Let us know what you think