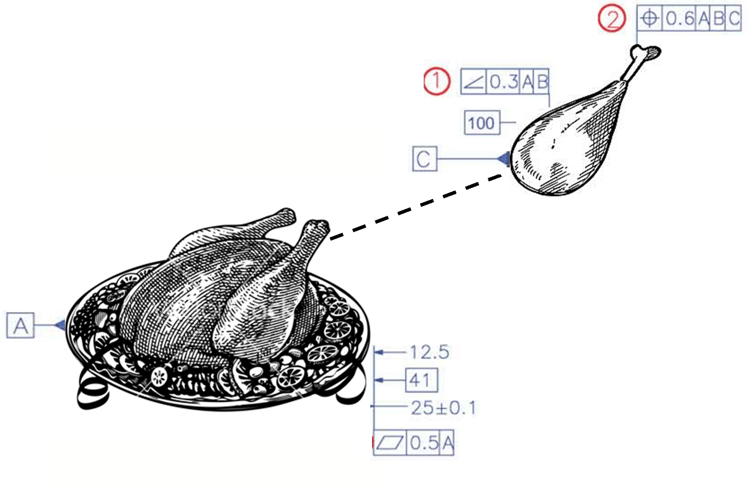

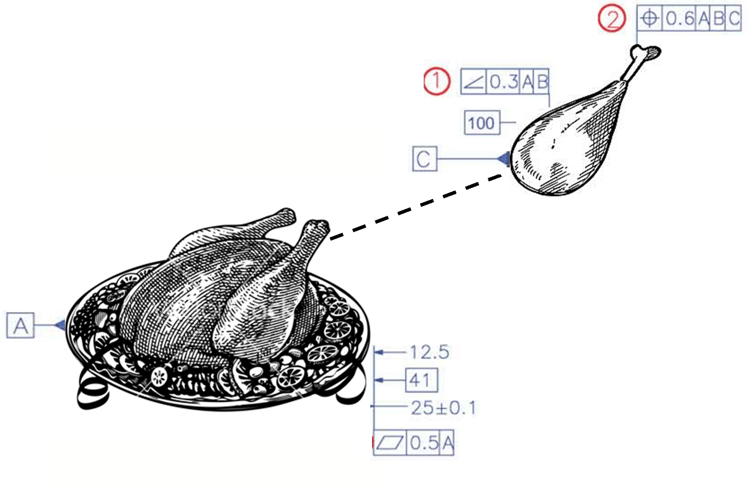

We all know that quality departments make sure that every part made at any manufacturing plant is perfect. We know this because the CAD model shows us how the parts fit, and their exact dimensions, and of course, when made, those parts always conform to those exact specifications as long as you measure them and file the measurements away in a closet, or drawer, or whatever. The point is, having a quality department ensures that your parts are perfect every time, and we can use this same mindset along with buzzwords to ensure that all other aspects of our lives are also perfect, especially the holidays.

How do we go about doing that you ask?

Let me show you!

Everyone knows that with Digital Transformation, if you put everything into the computer, it means everything will come out perfect. By digitizing your processes, you ensure that they are not only perfect, but that everyone is immediately following them and doing them perfectly, and your quality team naturally will ensure this through the use of magical quality process standards or something. Nobody actually knows how the quality teams ensure quality, so there is no point in mentioning it here. The point is, you need everything on the computer because that is digital, and Digital Transformation makes everything perfect.

Source: https://lprdrocketry.wordpress.com/2015/11/23/update-11222015-gobble-gobble-happy-thanksgiving-learning-cad-and-testing-valves/

For your holiday, begin with Digital. Digital is important because it provides synergy*, and we all know that synergy* is the backbone of how businesses function and succeed.

*synergy is important and comes in many flavors. We recommend lime favored synergy, and gin-flavored synergy for those hard days. Always consume synergy responsibly. Don't give synergy to minors.

Do this by finding someone else's Thanksgiving dinner on the computer, printing it out, and putting it in the kitchen. Once you do this, it will be impossible for your dinner to look any different or fail in any way. After all, you have the perfect design RIGHT THERE in front of you, so how could actually making it create any other outcome, right?

https://www.harmonsgrocery.com/product/traditional-turkey-dinner-medium/

Once you've completed your digital design and distributed it to the manufacturing plant (kitchen), it is time to collect your raw materials.

Naturally, it doesn't matter where you get them, as your end product will be the same no matter who the supplier is. Here are a couple of supplier recommendations, depending on your budget or money or location or whatever. Just go the cheap route, it won't completely mess up everything ever.

nice.

nice. yikes. (pick this one)

yikes. (pick this one)

nice.

Don't forget the other things, like potatoes, and cranberries or cranberry sauce or berry sauce, or some sauce, and beans, and rolls. You know, the stuff in the picture. Just remember to keep saying synergy* and to use (drink) your synergy* throughout the process.

Same thing right? C'mon, they're both BEANS.

Now get some process guides (recipes). Making your own process is like, totally last season, so feel free to steal someone else's. After they have done the design, tested it, perfected it, paid for all the failed attempts, and spent all that time working on it, it is probably fine for you to just borrow it. After your product is complete and perfect, you'll give it back or something. You can also just hire some of their people for a little while until you have it, then send them on their way. Nobody would mind that.

You're just borrowing the designs for a hot minute

Okay, now here you stand. You have a perfect design specification on your wall. You have a tried and true process guide, and you have the perfect materials from experienced and trustworthy suppliers (or whoever had them cheapest, it's the same thing).

IT IS TIME TO COOK.

Don't worry if your manufacturing space is different than the one used for the process guide. As long as you have the basics, you'll be fine. All manufacturing facilities are essentially the same, regardless of equipment type, age, quality, operator, and all that nonsense that consultants blather about. If it makes stuff, that's good enough, isn't it?

Their kitchen vs your kitchen. I'm sure it is fine. Source

Now that you have everything cooking, it is time to measure. Quality needs measurements to ensure compliance to specifications. This means you need to measure stuff. I don't know what that means either, so just like weigh stuff, and check the temperature, and like get a tape measure. It probably doesn't matter HOW you measure the dimensions, just make sure you have something on a spreadsheet.

Nobody knows what that means.

Speaking of spreadsheets, we almost forgot the most important part of quality.

Make sure to put all of your data in easily readable spreadsheets, as long as they are formatted differently.

Lots of spreadsheets. Oodles of spreadsheets. So many spreadsheets that your computer mouse can barely move and your PC gets so hot you can keep your thanksgiving dinner warm by setting it nearby. After all, spreadsheets are important and helpful, so more is probably better than less.

Then print all those spreadsheets out, put them in a box, and put that box in another box. Then, mail that box to yourself, and when it arrives - SMASH IT WITH A HAMMER!

Honestly, that's as good a use for them as any other.

Okay, so we have done all the things. Let's recap:

Excellent! You're on your way to the perfect Thanksgiving!

What could possibly go wrong?

Let's quickly cover some of the things to look out for, and how to fix them.

Ugh, who invited that guy? Okay, so it might not look EXACTLY like the picture, or it might not be juuuuuust right, but close enough is fine, isn't it? I mean, if it falls apart, catches fire, or fails to work, that's not your fault, right? You followed the directions, and so everything should be fine.

Photo : rothsara/Twitter

If it isn't, just blame the suppliers. After all, who are those people anyway? What do they know? They don't have the process guides, so they probably did something wrong. You can even call them and yell at them in front of whoever is complaining to prove that it isn't your fault. That always works.

The potatoes are charred masses of inedible rocks only good for holding down the massive stacks of spreadsheets you printed?

Okay, well throw them out and buy more!

Budgets probably don't matter anyway. They're just like, scribbles on paper and stuff, and money isn't even real anyway. The internet told me that. So just buy more stuff and do the EXACT. SAME. THING. AGAIN. If you burn enough of them, then eventually you will end up with unburnt perfect potatoes. Yes, that makes sense, do that. Just toss money at it, and it'll fix itself. Eureka!

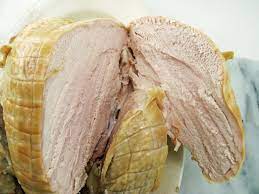

The turkey is undercooked and everyone is at the table, and there is no time, and your crazy Aunt is talking about what she read on Facebook, and...is someone crying?! Why is someone crying??!

Okay, time to rework this bird.

Go out to the garage and get that blowtorch you got for Christmas that everyone said you'd never use. Light that puppy up and get to work on that bird! It'll be 400 degrees internal temperature in no time! That's the specification, right? Someone read it for me. I can't see it with this metal mask on.

This looks safe. (PLEASE don't do this at home)

The quality team wants to see the measurements and other stuff you wrote down while making everything to see if they can understand why it went wrong.

You know what time it is. I know what time it is. Let's do this. It's time to FUDGE SOME NUMBERS!

After all, if it comes out that you did something wrong, you'll lose your job, or worse, get yelled at, or even worse, have to ADMIT you did something wrong! Unacceptable. Let us instead adjust the measures and numbers we have until they match the process guides, then it won't be clear at all where everything went wrong, and we'll just throw everything out, and start over fresh. Perfect. Then, put someone else in charge directly beneath you who has done it before and take credit when it goes right. No one will ever know, and you'll get a promotion!

Perfection.

After much testing, we have determined that 60% of the time, this guide works every time. Take our word for it. You can trust it, promise.

These Stories on T&T

No Comments Yet

Let us know what you think