Join Uli Decker, CENIT Solutions Manager Europe, and Don Jasurda, DCS Director of Sales, to learn how to take the next steps from design and tolerance software to enterprise quality driver

3DCS Variation Analyst is a CAD-integrated simulation software used by leading manufacturers in the aerospace, automotive, medical device, electronics, and machinery industries to create Digital Twins to simulate assembly processes and tolerance stacks using 3D models.

3DCS Variation Analyst stands out as the premier tool for tolerance analysis, going beyond simple 3D stack-ups to delve into the intricate relationships between parts while meticulously considering various sources of variation. This comprehensive approach delivers precise results, empowering users to make critical decisions regarding their design and manufacturing strategies with confidence.

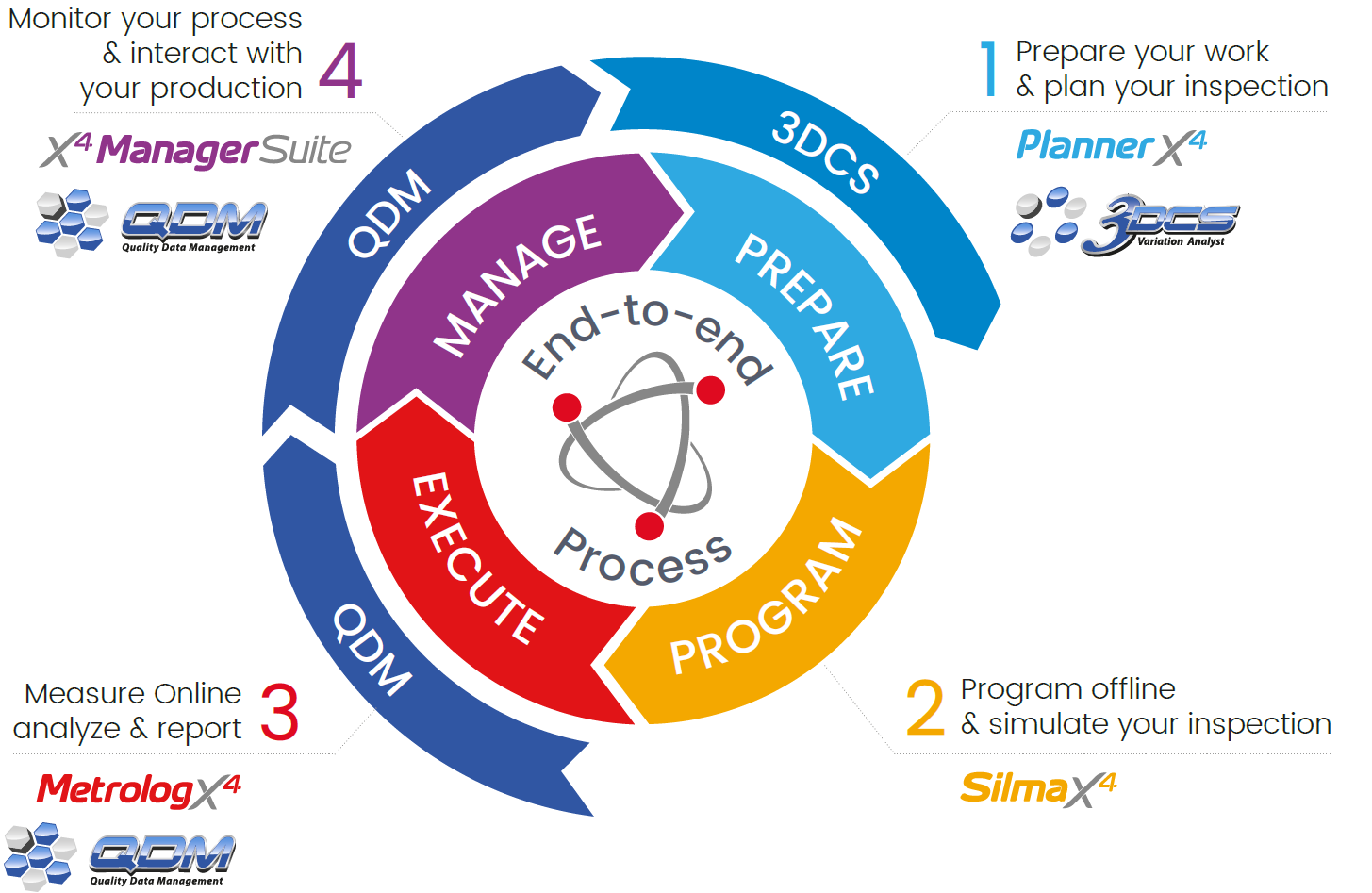

3DCS Variation Analyst becomes truly transformative when utilized to power downstream tools and processes. Connecting 3DCS with a Quality Management System, such as QDMWEB QI, from DCS, provides new tools to tackle your quality and reduce risk throughout your manufacturing and production processes.

Leveraging the data collected from the shop floor within 3DCS Variation Analyst through a Quality Management System, users gain insight into the origin of production challenges, identify mean shifts, and optimize their locating and datum strategies. Furthermore, platforms like QDMWEB QI offer invaluable assistance in quality control processes, facilitating the creation of Corrective and Preventative Actions (CAPA), setting up alerts to address trends and events to remove outliers, generating compliance reports (FAI and PPAP), and supporting standards such as APQP and other similar processes.

Learn More From the DCS 2024 Webinar Series -->

These Stories on CATIA

No Comments Yet

Let us know what you think