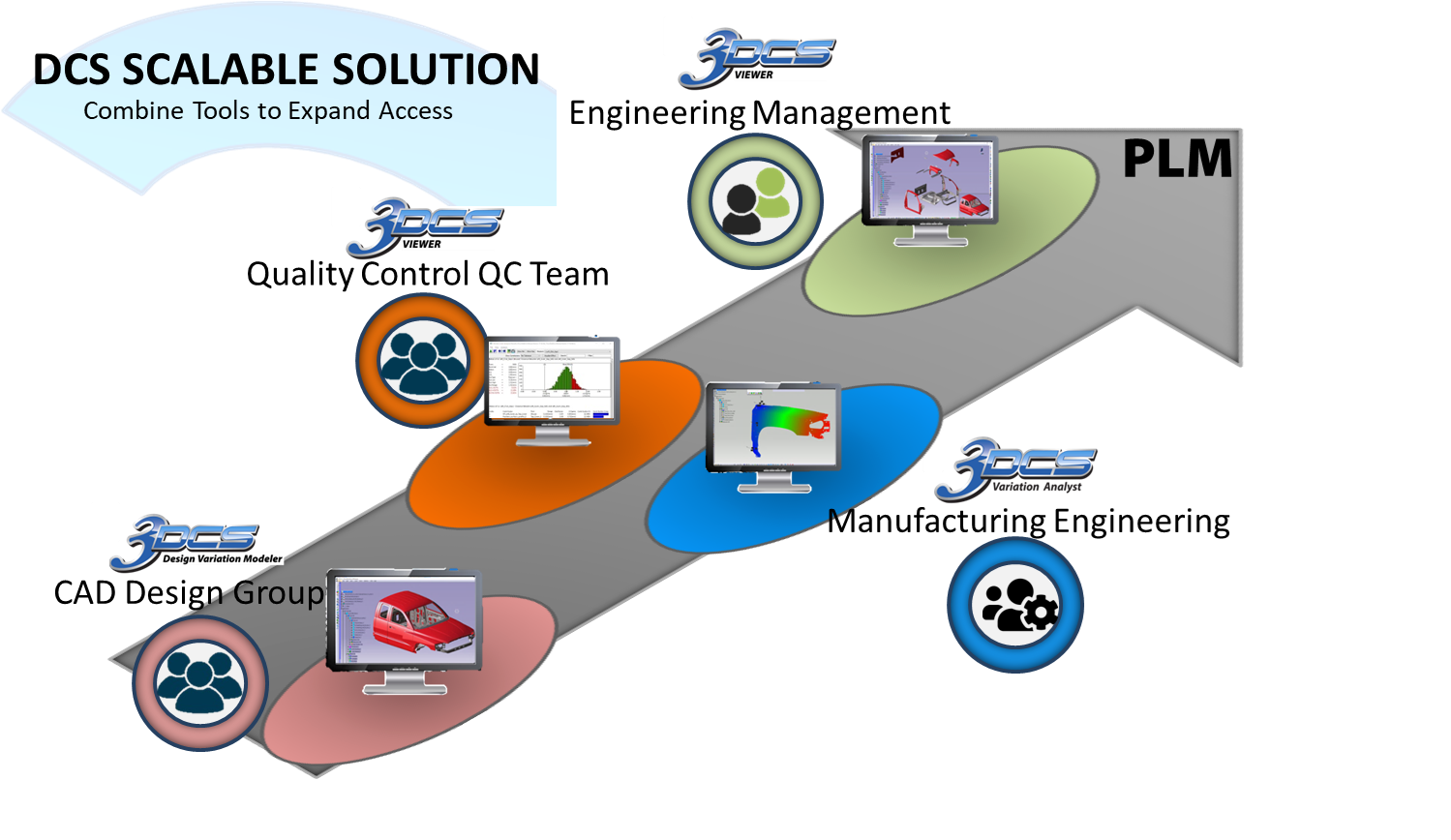

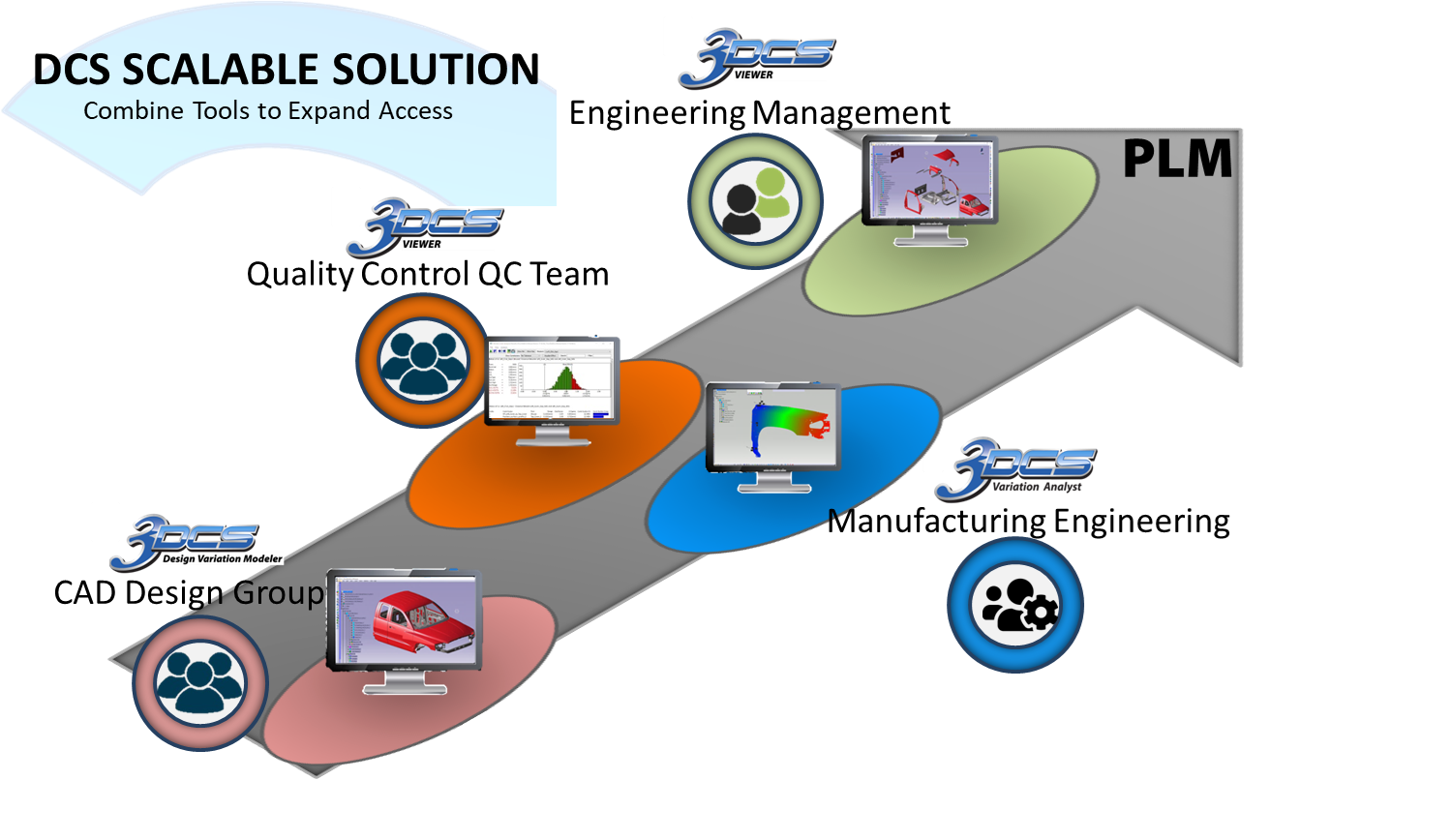

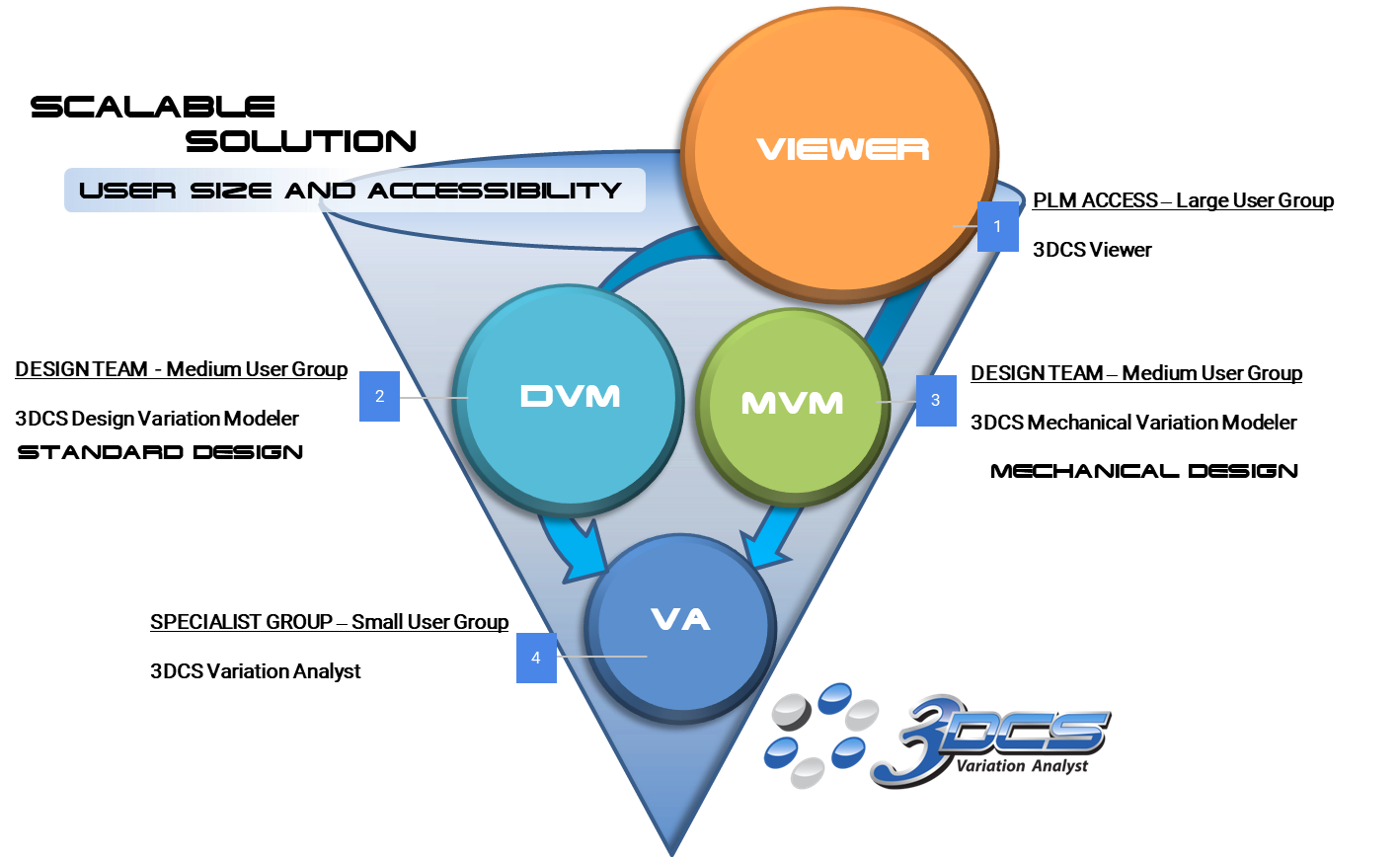

The DCS SCALABLE SOLUTION is a family of software products that provide simulation, analysis, and model visibility to your organization. By combining different tools, you can fully leverage your PLM Systems and Model-Based Engineering Processes to drive quality throughout your organization reducing scrap, rework, and non-conformance on the way.

The DCS SCALABLE SOLUTION provides 4 software tools for your team depending on the level of analysis and model access each user group needs. Utilize a combination of these tools at your organization to spread awareness, and begin modeling and analyzing farther upstream with easy-to-use analysis and modeling tools.

To begin analysis as early as possible in order to reduce the risk of non-conformance, 3DCS Design Variation Modeler DVM provides a fast, efficient, and true 3D analysis tool for your Design Group. This allows Designers to quickly learn and start running tolerance stack-ups as they design the parts and specifications. By providing a realistic look at your product in these early digital phases, your design will be more robust from the beginning, reducing the amount of simulation, problem-solving, and risks farther down the product lifecycle.

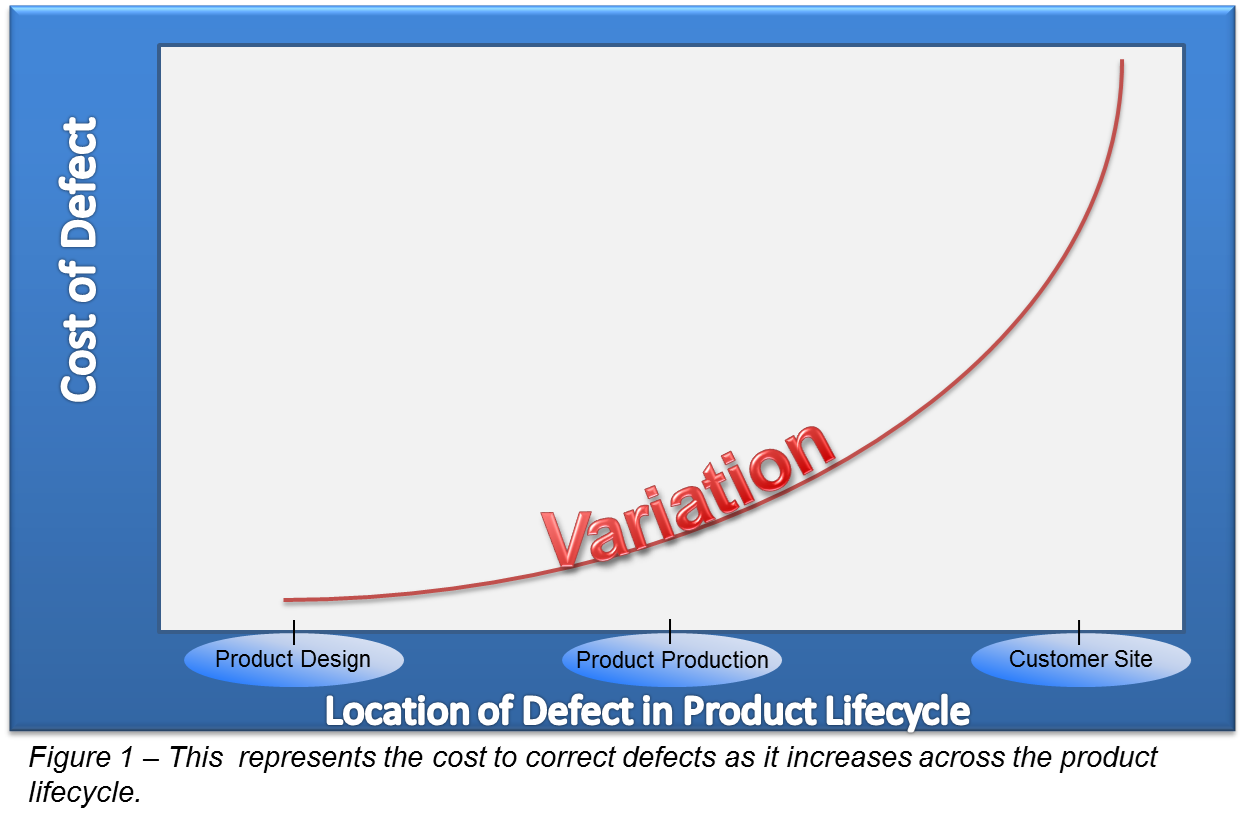

The earlier in the Product Lifecycle a potential problem can be found, the less expensive it is to fix, potentially saving millions of dollars in manufacturing costs.

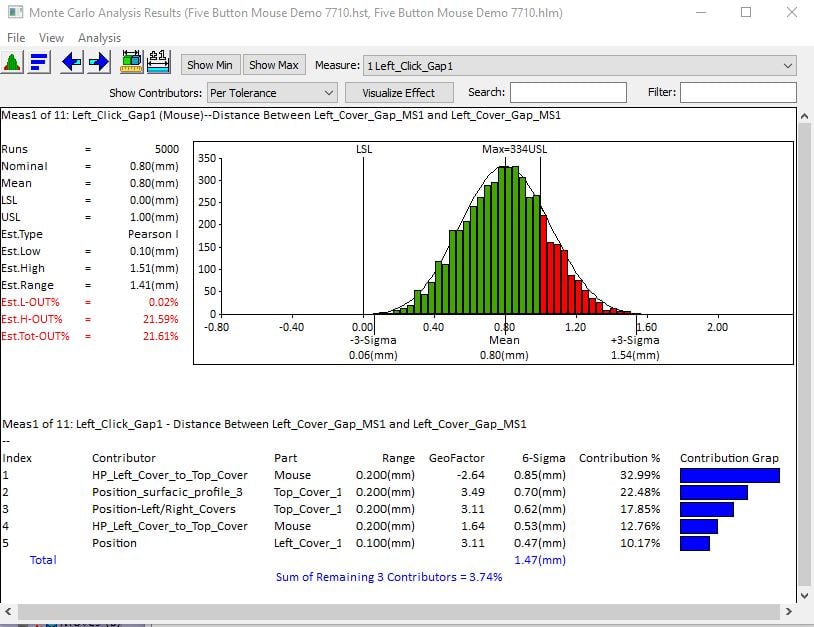

After the initial CAD designs are complete, the Manufacturing Engineering team can utilize 3DCS Variation Analyst, the full toolset, to complete advanced simulation models and create a true Digital Twin, a fully working digital prototype, to validate and test assembly methods, manufacturing processes, tolerance stacks, datums, and tooling. The outputs of these analyses provide the information to optimize the model, creating a robust design with reduced risk of non-conformance, build issues, and tolerance problems.

Simulation Results Provide Deep Insight Into Your Product to Empower Decision Making

Once the model has been completed, Engineering Management and Quality Control can use 3DCS VIEWER to interrogate the model, viewing assembly processes, model features, tolerances, GD&T, and review the analysis results. This allows for unprecedented access to product information to make important decisions about measurement plans, inspection, and tooling fixtures.

Once production begins, the model becomes a powerful root-cause analysis tool with 3DCS Variation Analyst. By feeding back inspection data from the plant into the original simulation model, problems found in production can be quickly root-caused, and the information on the issue, as well as possible solutions, shared in complete detail through the company's PLM System and accessed with 3DCS VIEWER.

Create user groups of tools based on complexity and accessibility. With 3DCS Viewer accessible to a larger group, you can bring real 3D Model-Based Definition into your organization to drive your Digital Transformation, leveraging information in the model instead of 2D outputs and reports.

View Dimensional Variation Analysis DVA models and see the results of analysis as well as inputs, configuration, and assembly method using the 3D model.

Easy-to-learn and use 3D analysis that provides a more accurate output than 1D stacks in Excel. Allow your Design team and engineers to get answers faster than calculating stack-ups, while preparing the models for more complicated analysis by the CAE team down the line.

Designed for mechanical and kinematic products, MVM provides more options than DVM including a larger set of PMI options, the ability to extract assembly constraints from CAD, and analysis of complex and kinematic assemblies. As one of the two intermediate tools, MVM provides a more focused team the tools they need to get answers in order to make important decisions on design and quality.

The flagship version of 3DCS, 3DCS Variation Analyst includes the entire suite of tools for advanced dimensional analysis. As an advanced CAE tool, 3DCS Variation Analyst performs best in the hands of a specialist team looking at complex problems and working to create robust designs that account for variation at both the part level and in the assembly and manufacturing process.

These Stories on CATIA

No Comments Yet

Let us know what you think