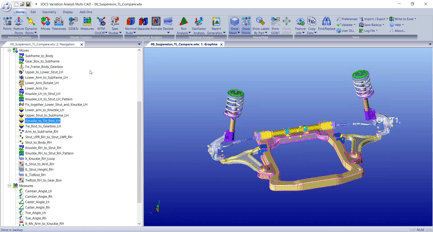

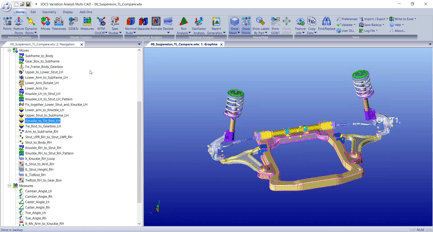

3DCS Mechanical Variation Modeler is built on the 3DCS platform incorporating 3DCS Mechanical Modeler into its base functionality to model complicated linkages and mechanical assemblies with easy-to-apply Constraints, Joints, and a DCS Feature Move.

By modeling the assembly process, and determining the risk and source of part failures, manufacturers can optimize their design to account for both process and part variation, reducing non-conformance, scrap, rework, and warranty costs.

3DCS Mechanical is a standalone or CAD integrated application, designed as a less complex tool compared to 3DCS Variation Analyst, and focused on mechanical joints and constraints to make modeling more intuitive for mechanical assemblies.

3DCS Mechanical Variation Modeler, just like 3DCS Variation Analyst, gives outputs based on part and process variation. These can be input in a variety of ways, from CAD-based PMI, extracting Joints and Constraints from CAD, to selecting feature and point-based options in the software. The final results are shown as statistical (Monte Carlo) and mathematics (Sensitivity) based outputs with toggle-able metrics including Cpk, Ppk, ranges, percent out of specification, and a variety more.

3DCS Mechanical Variation Modeler Value:

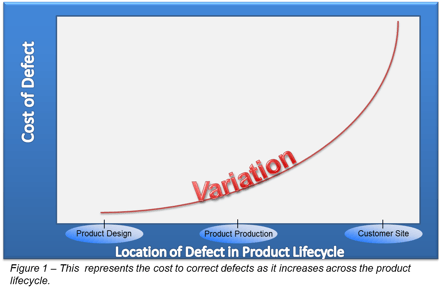

It is well known that the earlier in the Product Lifecycle an issue is found, the cheaper it is to fix. When a product is still in the digital design phase, an engineering change can be as simple as a click of a mouse. However, as soon as the product gets into the customers' hands though, a simple engineering change may mean recalls and warranty claims. This costs exorbitantly more than updating a CAD model.

Creating digital twins for tolerance analysis has become an important part of many OEM's product development processes. CAD simulation and analysis gives engineers the opportunity to validate their assembly process and tolerances early in the Product Lifecycle, and to make relevant, inexpensive changes before tools are cut. Simulation, optimization, and validation in the digital environment has been proven to save millions of dollars in production costs, and this number only grows as both the tools and the users become more advanced.

These Stories on CATIA

No Comments Yet

Let us know what you think