Thursday, June 3rd Concludes the DCS Global Technology Conference Event by Adding Three New Presentations - Two from Leaders in Dimensional Quality at Stellantis, and a workshop from FEA Specialist Maria Harangus of DCS

Not Registered? Click to Message us and get registered

Day 4 is a series of 6 new presentations, over a 2-day extension of the DCS Global Technology Conference. This expands the event to 35 presentations, with even more on-demand only, providing a truly massive amount of value.

Each of the Day 4 Events consists of 3 back-to-back presentations held in the late morning EST using the same Gotowebinar link to join. This makes it easy to log on and attend the sessions you want. Each session will begin on the hour, so if you only want to watch a single session, you can log in at its start time to catch just what you're interested in seeing. After each day concludes, you'll be able to watch the presentations on-demand on the DCS GTC Event Site.

- Christopher Slon, Technical Fellow, Dimensional Quality - Stellantis

Christopher Slon has overseen the expansion of 3DCS and QDM at Stellantis, working them into the Stellantis quality process in order to support design, launch, and production needs. Learn how Stellantis implemented these tools as part of their process, how they are benefiting, and the very real impact it has on improving quality and reducing costs.

Abstract:

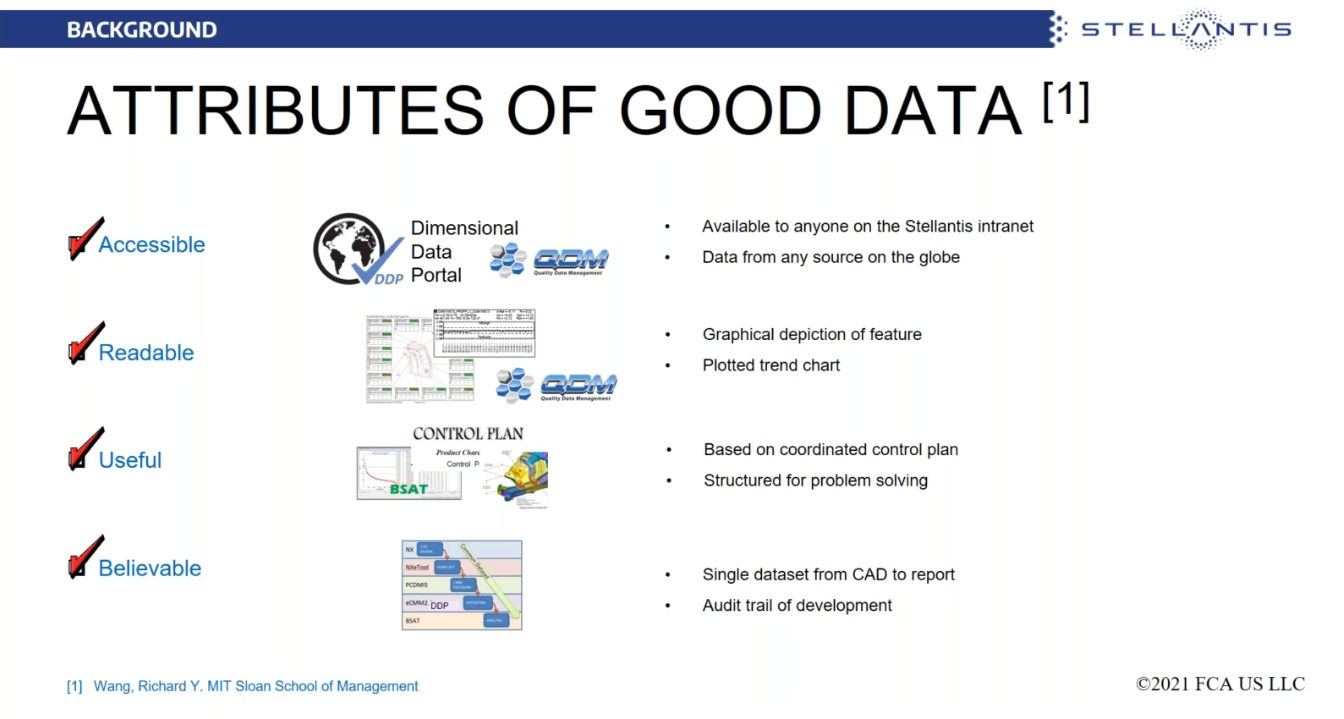

Maintaining dimensional quality throughout the life of an automotive product is dependent on proactive, reactive, and preventive problem-solving. Proactive problem-solving is the hard-to-measure process of avoiding causes of problems before the product design reaches the plant. Reactive problem-solving is the process of identifying the causes of dimensional problems once the product is in the plant and eliminating them as quickly as possible. Preventive problem-solving is the ability to prevent new problems from arising in the plant through predicting the causes of quality deficiencies. In all these cases, good data is the foundation of effective problem-solving. Good data is defined as data that is accessible, readable, useful, and believable.

Stellantis recently deployed DCS's QDM to provide good data for problem-solving. This presentation describes how QDM-Web has helped Stellantis deliver good data for problem-solving.

Not Registered? Click to Message us and get registered

- Amandeep Jhajj, Technical Specialist- Dimensional Quality at Stellantis (formerly FCA Fiat Chrysler Automobiles)

Amandeep Jhajj has been instrumental in applying 3DCS tools to identifying and resolving possible production issues by balancing risk, analysis, cost, and inspection in order to produce a product of the highest quality. Learn how Amandeep Jhajj applies 3DCS as part of the Stellantis process through the use of 3 example projects; one in design, one in launch, and one in production.

Abstract:

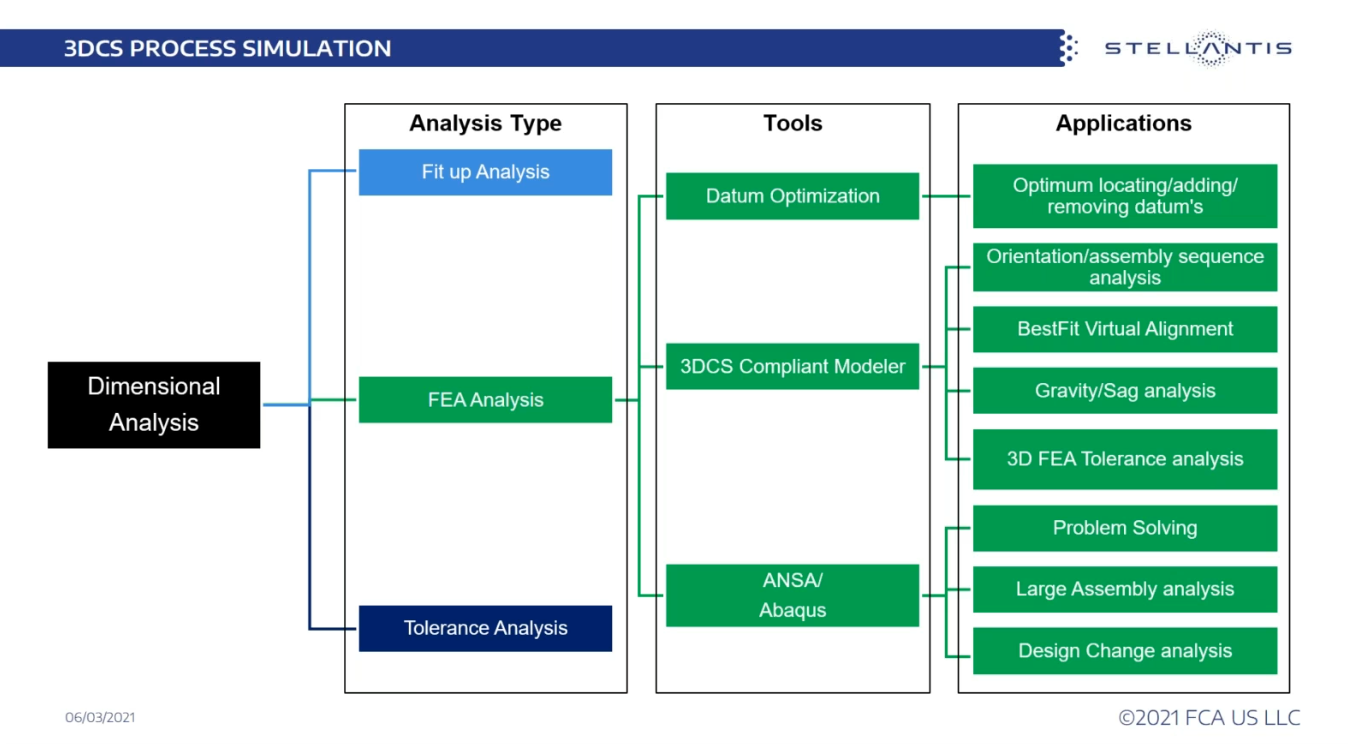

The concept of a digital twin was first developed by NASA as a cost-effective way to predict the performance of a spacecraft design with minimal testing. The concept is getting exposure in manufacturing as a way to reduce costs in the launch by avoiding problems through the design process, fixing problems faster in the launch phase, and preventing problems in ongoing production.

The kind of high-fidelity model or a manufacturing process that can truly be called a digital twin is still some ways off, but this presentation looks at how 3DCS has brought Stellantis a step or two closer to that vision.

Not Registered? Click to Message us and get registered

- Maria Harangus, Sr. DCS Dimensional Engineer

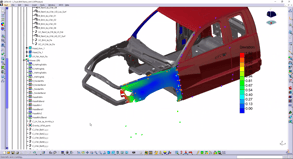

Expanding on the May 27th presentation, Maria Harangus shows 3 models and how Finite Element Analysis can be incorporated into them to improve analysis accuracy: Aircraft Skin to Stringer, Automotive Exhaust System, Automotive Fender. See how the material properties cause these products to warp, twist, stretch, and flex when they are attached, in use, and assembled.

Traditional variation analysis methods are considered to be "rigid-body" or "non-compliant" modeling; meaning, that every part

While this might be the case with a few machined components, most commodities and materials like sheet metal, plastics, aluminum, etc. can be heavily influenced

3DCS FEA Compliant Modeler, an add-on module to the 3DCS software solutions, utilizes FEA methods to accurately simulate the variation of compliant parts and assemblies within the 3D Variation Analysis model.

Not Registered? Click to Message us and get registered

These Stories on CATIA

No Comments Yet

Let us know what you think