Why do Single Part Analysis?

If a single part is fabricated by going through multiple steps:

What can you get from Single Part Analysis?

(Can you meet final part GD&T?)

Think about a 3DCS Variation Analyst model. It contains some math data, with GD&T for important part features, some moves (instructions to put the parts together), and some measures to get the functional and quality output we need to predict how our assembly will work in the actual manufacturing process.

…but what about the other way?? Suppose we need to model a machining process.

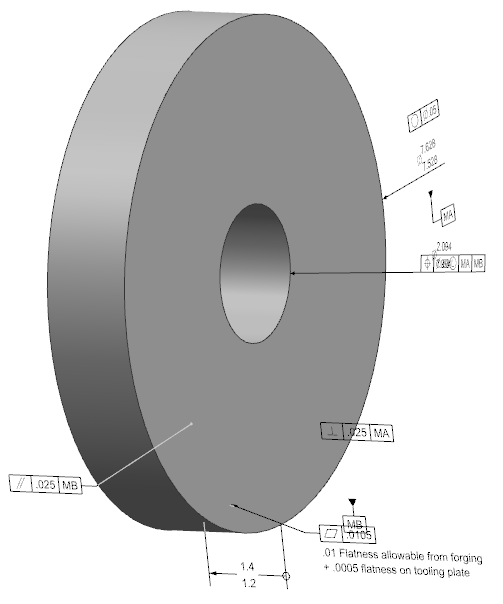

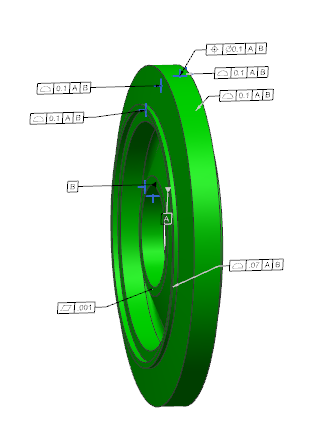

Our process begins with a blank part…

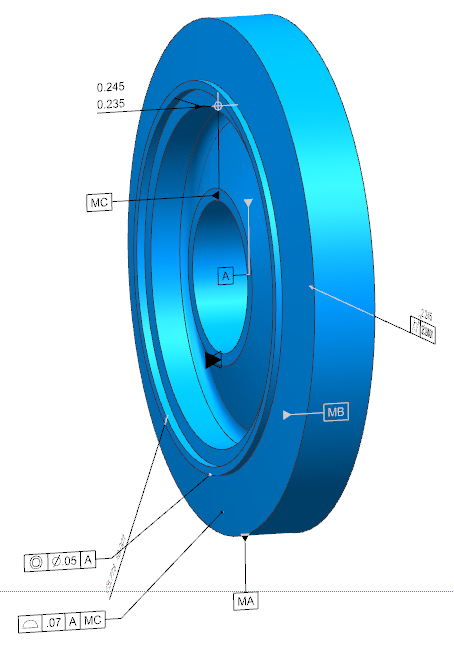

… it gets placed in a fixture or tool, and some new features get created – holes, slots, machined surfaces, etc.

The in-process part ends up on another fixture, more features get created, and we move the part to the next step in the process. This series of process may even remove ALL of the surfaces from that original, blank part.

How does 3DCS VA analyze this sort of process?

3DCS Variation Analyst can be used to model your multi-step manufacturing process!

Moves are used to specify how the part is located in your tooling during processing or measurement.

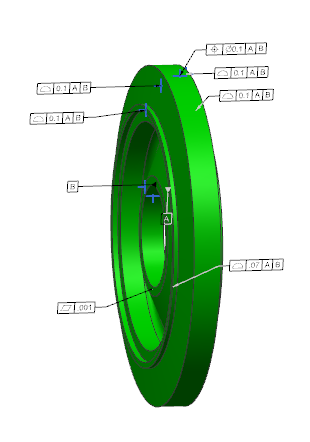

Tolerances or GD&T applied to surfaces and features will reflect the capability of your manufacturing process.

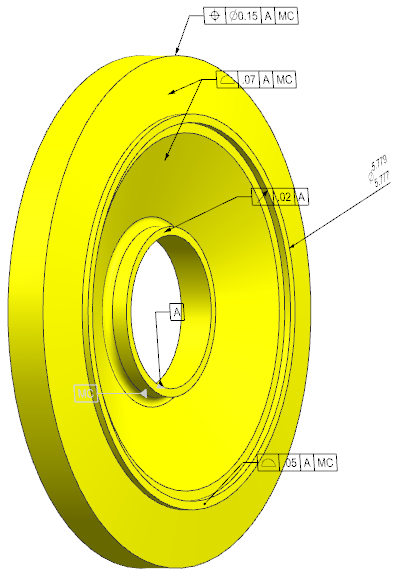

Apply measures to evaluate your completed part. Does it meet the requirements on your drawing? Do you have enough material for cleanup? Use the Monte Carlo analysis results to determine which steps are affecting which outputs.

At the end of your modeling effort, you have a simulation tool you can use to improve your process, or find ways to reduce your manufacturing costs.

Give our video a watch, and see Gary Bell quickly use extracted PMI to analyze the process that takes a part from a blank to a finished piston.

Want to see more?

Click to get access to the DCS Global Technology Conference On-Demand

These Stories on CATIA

No Comments Yet

Let us know what you think