October 26th - How To Do Closed Loop Quality -- How to incorporate real data into your analysis. Find mean shifts, root cause production issues, test changes.

Date: October 26th, 2017 (Now available on demand!)

Time: 11:00 am EST to 12:00 pm EST

Location: Gotowebinar

Running Monte Carlo Simulations give a statistical understanding of what is possible, but what do you do when issues arise during manufacturing?

Closed Loop methodology is the idea of feeding measurement data from production back into tolerance analysis software to root cause and resolve production issues. This helps find the true source of the issue and then validate changes to resolve the problem.

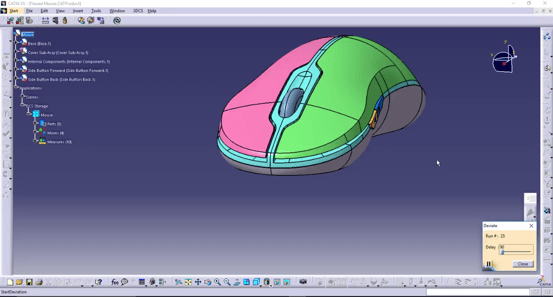

Using measurement data from a CMM can give real insight into your production line, and help you discover mean shifts and product variation that may not have been represented in your simulation. The ability to create a measurement plan, including CMM coordinate measurement points, and then quickly incorporate the measured data back into the model, gives users the ability to provide the points that they need measured, connect the measured points to the points in the model, and then run new analyses based on the measured data.

Agenda --

Agenda --

Follow Gary Bell, DCS ASME Certified GD&T expert and Senior Variation Analyst, as he shows how to bring production data into 3DCS and see how mean shifts in manufacturing can be analyzed, how problems can be sourced and solutions validated.

These Stories on CATIA

No Comments Yet

Let us know what you think