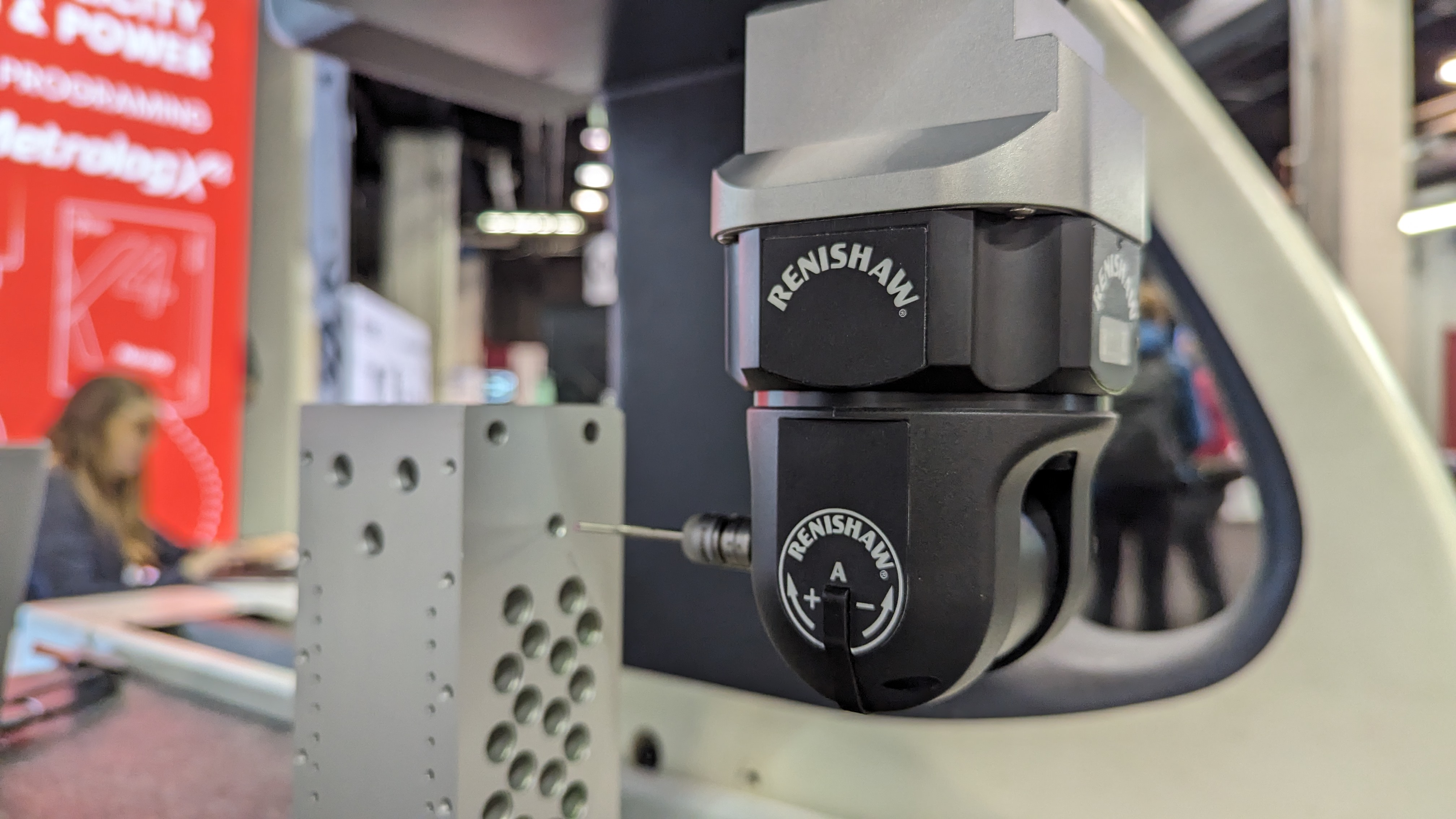

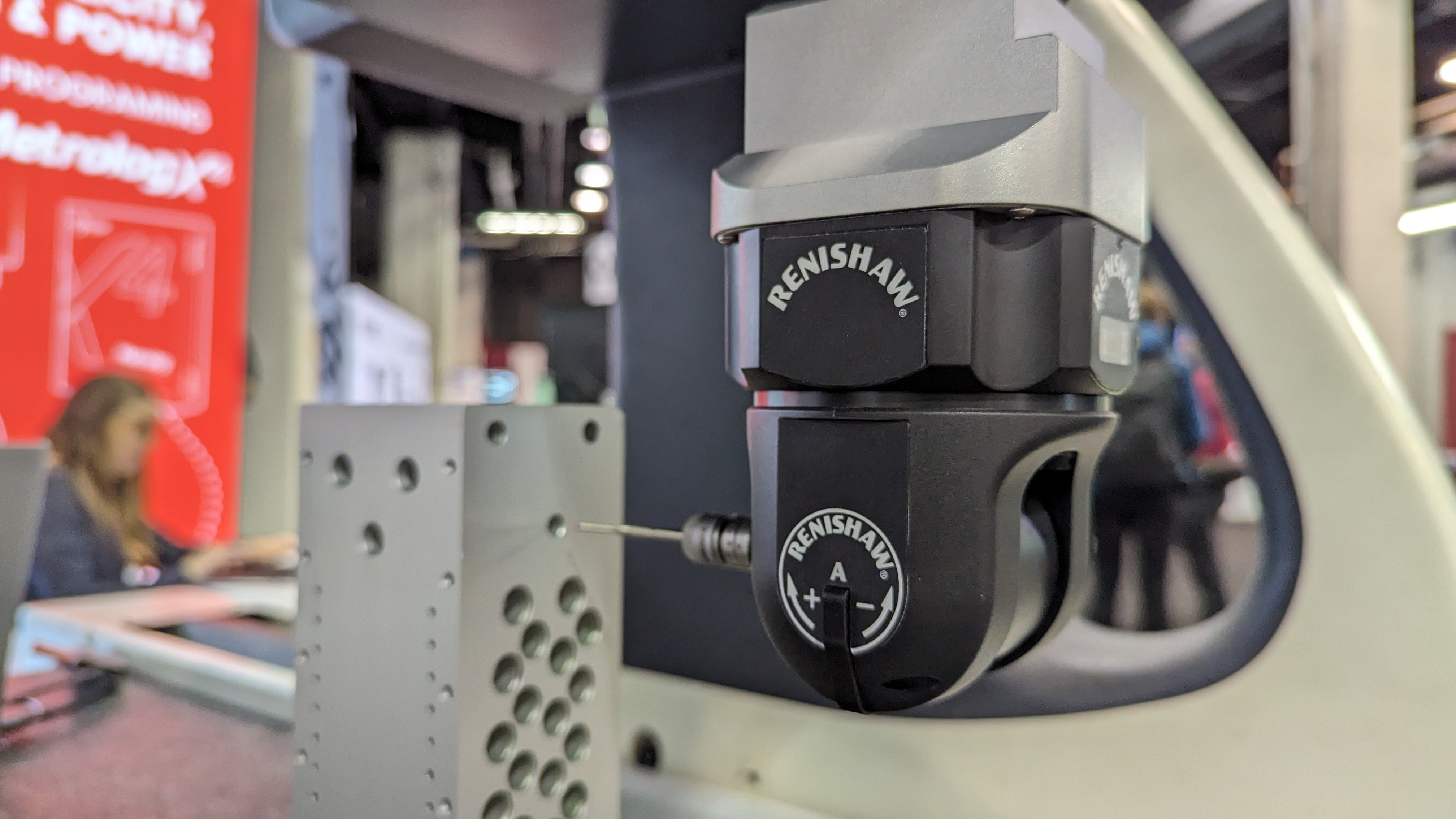

The Quality Show brought together professionals from various industries, all facing similar challenges and seeking solutions. One of the key takeaways from the event was the importance of metrology in measuring parts to determine if they meet specification standards.

However, metrology alone does not provide guidance on what to do with parts that are found to be out of specification. This raises important questions: Can these parts still be considered good? How do we determine where to measure? And what should be done with the collected data?

Recognizing these challenges, Sandvik has brought together a family of companies to address these issues comprehensively. DCS offers valuable insights on where to measure, while Metrologic specializes in simulating and programming machines to measure parts faster and more accurately, enabling a more precise assessment of quality. DWFritz, on the other hand, provides high-speed non-contact measurements to ensure uninterrupted production line operations. Lastly, DCS provides a backend system that efficiently collects and organizes all measured data, making it accessible and usable for your teams.

By combining the expertise and capabilities of these companies, Sandvik's metrology solutions offer a holistic approach to quality control and data management in manufacturing. This integrated approach not only improves efficiency and accuracy but also streamlines decision-making processes, allowing manufacturers to make informed choices about out-of-specification parts and optimize their production processes.

To learn more about Sandvik Metrology Solutions and discover more about the highlights from the conference showcase, visit https://www.manufacturingsolutions.sandvik/en/our-offering/metrology-solutions/

These Stories on SPC

No Comments Yet

Let us know what you think