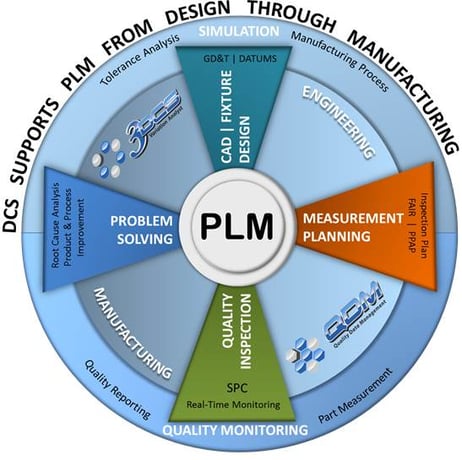

The Industrial Internet of Things connects design and manufacturing to give true production visibility

The Industrial Internet of Things (IIot) is the connection of devices within manufacturing to communicate without the need for manual input or involvement. In a manufacturing environment, this usually takes the form of inspection and measurement devices connected to a central database to collect, organize and standardize data to provide information for decision making.

No Such Thing as Perfect Parts

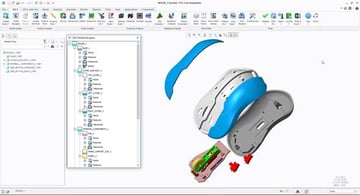

As any engineer or manufacturer will tell you, when parts are made, they are never nominal. When designed in CAD, parts are made to perfect specifications, and are often made to general tolerance specifications not taking actual production processes into account. As a result, when these parts are actually made, they can come out too big, too small, or create compound variation stacks that can cause unforeseen issues in assembly.

As any engineer or manufacturer will tell you, when parts are made, they are never nominal. When designed in CAD, parts are made to perfect specifications, and are often made to general tolerance specifications not taking actual production processes into account. As a result, when these parts are actually made, they can come out too big, too small, or create compound variation stacks that can cause unforeseen issues in assembly.

Tolerance Analysis in Design – Continuous Improvement

In order to compensate for this inherent variation in manufacturing, companies use tolerance analysis and simulation to improve the design to account for variation. 3DCS does this through Monte Carlo Analysis, using a random number generator and a normalized distribution curve to evaluate designs and manufacturing processes to find issues from variation. By finding contributors to variation, and running simulations, engineers continually improve designs to tighten key tolerances and loosen less important tolerances that might be 'over-engineered'.

In order to compensate for this inherent variation in manufacturing, companies use tolerance analysis and simulation to improve the design to account for variation. 3DCS does this through Monte Carlo Analysis, using a random number generator and a normalized distribution curve to evaluate designs and manufacturing processes to find issues from variation. By finding contributors to variation, and running simulations, engineers continually improve designs to tighten key tolerances and loosen less important tolerances that might be 'over-engineered'.

Manufacturing Quality Systems – Using QMS to Monitor Production

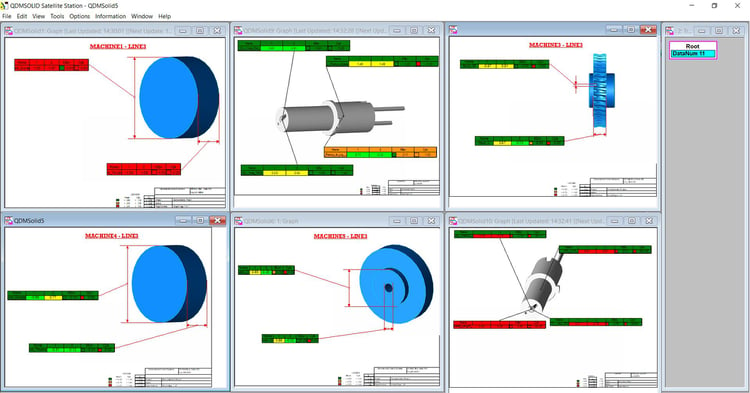

When the design is completed and sent to manufacturing to be produced, it is important to give plants and facilities the tools to monitor production for out of spec parts. A QMS -quality management system - is a central software system placed on a server - either locally or in the cloud - that collects inspection and measurement data and delivers quality reports, dashboards and real time monitoring information.

QMS software systems have traditionally been very expensive and taken a lot of time to set up. This stems from the complexity of setting up a server based system internally at large manufacturers that encompasses a large number of plants, inspection devices and users. As QMS systems become more advanced, they also become cheaper and easier to implement. By incorporating the Cloud, QMS systems can be managed by their development team, reducing IT burdens, and allowing for nearly instant setup.

QMS software systems have traditionally been very expensive and taken a lot of time to set up. This stems from the complexity of setting up a server based system internally at large manufacturers that encompasses a large number of plants, inspection devices and users. As QMS systems become more advanced, they also become cheaper and easier to implement. By incorporating the Cloud, QMS systems can be managed by their development team, reducing IT burdens, and allowing for nearly instant setup.

QDM Web is a quality SPC system that can be quickly put in place by using QDM Cloud to start monitoring production in real time, and using dashboards to quickly understand changed in production quality. With small monthly costs instead of large package deals, QMS software like QDM Cloud can give smaller manufacturers access to QMS technology that would have previously been too expensive to obtain.

Automated Quality Systems Promote Quality Improvement and Production Visibility

A standing QMS software system automates the collection and standardization of measurement data. Whether using hand gages, CMM's or visual scanners, this data can be put into a database to be mined for information to understand production quality and changes in manufacturing processes. Through constant monitoring, production issues can be identified before out of spec parts are made, reducing scrap and downtime.

Most large manufacturers understand the need for a QMS software solution. Without such a solution, quality information is often difficult to process and understand quickly, leading to more reactive quality control. Correcting quality issues when out of spec parts are already being made can lead to plant shut downs and high volumes of scrapped parts that can be a difficult burden for manufacturers, both small and large.

With the move to the Cloud, large and medium manufacturers can also bring their supply chain into the system, sharing the benefits with the supply chain. By leasing a monthly license from the Cloud, instead of having to install large expensive software packages, suppliers can upload their data to the system, giving visibility into their parts before they are shipped to the customer. Quality issues can be found, root caused and resolved before any parts arrive for assembly, and suppliers themselves gain the ability to check their own parts from their customer's perspective to ensure they are meeting quality requirements before turning any information over to their customer.

This improves quality across the entire product life cycle, and helps both small and large manufacturers reduce expensive waste. It also reduces headaches for manufacturers. Having a reduction in stress is never a bad thing. Afterall, going from red lights and emergency issues from bad parts arriving from a supplier or coming off the line, to an email alert, quick report to identify the problem, and creating a simple work order to resolve it, is a drastic improvement.

Using IIoT to Feed a QMS Software System

How does IIot it into this equation? As devices become more interconnected, it becomes easier to automate processes that were previously manual. CMM data can be instantly uploaded to the network and used by a QMS, hand measurements can be entered into a tablet (instead of written on a clipboard) and within seconds added to the QMS database, visual scanners to save outputs directly to the QMS database. This means that without any manual effort, all of your production information is always available with a few button clicks. This makes it easier to keep an eye on production, and with real time monitors and automated alerts, keeps all stake holders up to date on current manufacturing trends.

Feeding Back to Simulation - CAD Based Problem Solving

With a QMS software system in place, information can be fed back to early stages to continually improve designs and to root cause and resolve problems. By bringing measurement data back into CAD, and using tools like 3DCS Variation Analyst to simulate as-built products, engineers can find the true source of variation problems and test solutions before implementing them in production. This can take the trial-and-error approach of fixing plant issues out of the equation, and taking that cost off the books, while also improving designs for future projects. What's more, with a QMS software system, this can be done easily, without special training or extra translators. (Find out how at DCS's October Webinar!)

Closing the Loop on Quality

Connecting devices and systems using the IIoT creates an interconnected system of automated processes that includes feedback loops of data to validate and quality check along the product life cycle. This promotes a continuous improvement process that can reduce expensive quality issues found in traditional manufacturing processes that end up creating scrap and defects. Manufacturers are using these methods to improve their bottom line and increase profits without having to sell additional product.

Want to try QDM Cloud yourself? Try it free, and then start using it for as little as $158 a month!

These Stories on 3DCS

No Comments Yet

Let us know what you think