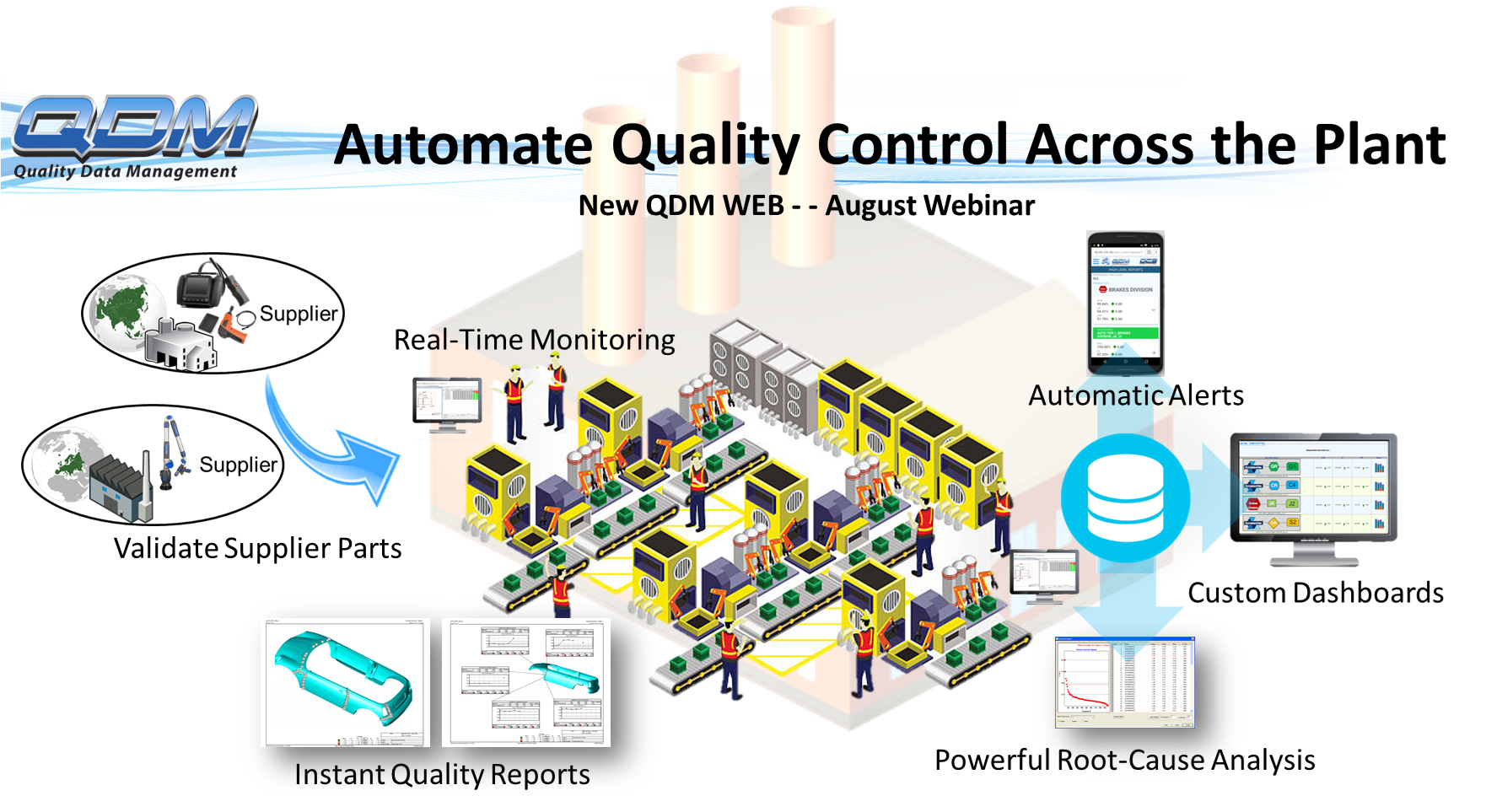

Don't miss out on this month's QDM WEB SPC System Webinar

Every engineer has a horror story of receiving parts, and then seeing those parts fail to fit, work, or meet specifications. This forces a flurry of activity that includes angry phone calls, finger pointing, and most often expensive, fast shipping of parts back and forth (hopefully not by plane!).

These kinds of complications do more than upset people on both sides, supplier and OEM, they also cause delays in production, and expensive rework, and shipping costs.

The answer, of course, is to get measurements from suppliers before parts are shipped so that the parts can be verified that they meet specifications before being sent. This leaves a number of problems that need to be addressed:

1. Data Sharing - how are suppliers communicating their measurement data efficiently?

2. Measurement Correlation - are the suppliers measuring correctly?

3. Root Cause Analysis - how do you keep the problem from reoccurring on following production batches?

Most systems fail to answer all of these issues.

They might provide a means to communicate data, but then your engineers need to crunch all the data and determine if the parts meet specifications.

They might provide a measurement correlation, but do so manually, simply providing drawings that leave a lot of room for interpretation, and therefore, error.

Some systems may provide data analysis, but won't provide a means of determining the true source of the problem, only the parts or machines causing the problem. The CAD or Manufacturing Engineering group are then left to try and use their CAD analysis to find a lasting solution to keep from having to rework every batch of parts.

Let's look at what a system that addresses these issues would look like.

You get a lot of email. That's a given. Using email to provide big spreadsheets for important part shipments is not secure, not efficient, and let's be honest, not functional.

QDM WEB as a Web based system (see what we did there?) offers two easy methods to communicate with your suppliers:

Provide your supplier with a login to your QDM WEB SPC System. With layered permissions, you can allow the supplier to see only their parts and systems, and interact with the features you want. This allows a supplier to upload raw measurement data from their measurement devices (CMM, FARO measurement arms, scanners, excel sheets) into the system and view that data after the system has processed it into quality information (which takes seconds).

Concerned about data security? Small suppliers or single project suppliers? A Supplier Portal is a webpage for your suppliers to visit where they can upload into the system and download information without accessing the QDM WEB system itself. This keeps your data up to date, and gives your suppliers an easy way to share and get the information both OEM and supplier need.

When uploading data, the system provides an easy process for viewing, and then either denying or approving the measurements from a batch of parts:

Almost all design is done in CAD platforms, so wouldn't it make sense that the measurement plans be created using the same design data?

Measurement Plans can be created using QDM ANALYST, part of a QDM WEB system and pulling directly from the CAD model to offer a clear view of where parts need to be measured, and helpful coordinates to use directly with CMM programming.

With these Plans available as easy to read pdf's and excel sheets of coordinates, Suppliers can then access them in one of two ways --

QDM WEB provides Measurement Plans to suppliers through two methods:

With a login into the system, suppliers can view their parts and directly download related information - measurement plans, drawings, quality documents, and other documents.

A Supplier Portal offers a single site to upload measurement data, and download measurement plans. Suppliers can easily share data securely, without it getting lost in your inbox, or filtered by your firewall.

QDM WEB really shines in providing problem solving tools to your organization. It does through a variety of methods - real-time monitoring, automated alerts, detailed reports, correlated data, and powerful root-cause analysis tools.

Using Plant Data Analyzer (PDA) Module for QDM WEB, quality professionals can dive deep into the data, mining for answers amongst the measurements.

QDM WEB provides a connection to CAD through correlated point data, but can also be used to provide measurement data to then analyze in your CAD system. We'll be talking about this more in coming articles, so make sure to subscribe to the Engineering Talk Blog.

Click Here to Register for the August 27th, 11 am EST

These Stories on CATIA

No Comments Yet

Let us know what you think