We encounter many situations where there is a form tolerance on a primary surface and then the other side of the part has a thickness allowance. Often implicitly it is assumed to have the same form or a very local refinement. (i.e. stamped sheet metal, composite lay-ups)There are many situations in both aerospace and automotive I would think where sheet of material is stamped and parts are indexed to both sides and sheet metal is accepted using a spec tolerance.

One method used in the past has been to use ghost parts but it seems like there should be an easier way. What am i missing?

DCS has enhanced 3DCS software to handle many special case scenarios. To handle material thickness, for example, two methods would include using a Dynamic Point or Copy a Coordinate Point to reference thickness and then deviate the points with tolerances. Here is a guide to setting up analysis of material thickness in 3DCS software.

3 Different Methods:

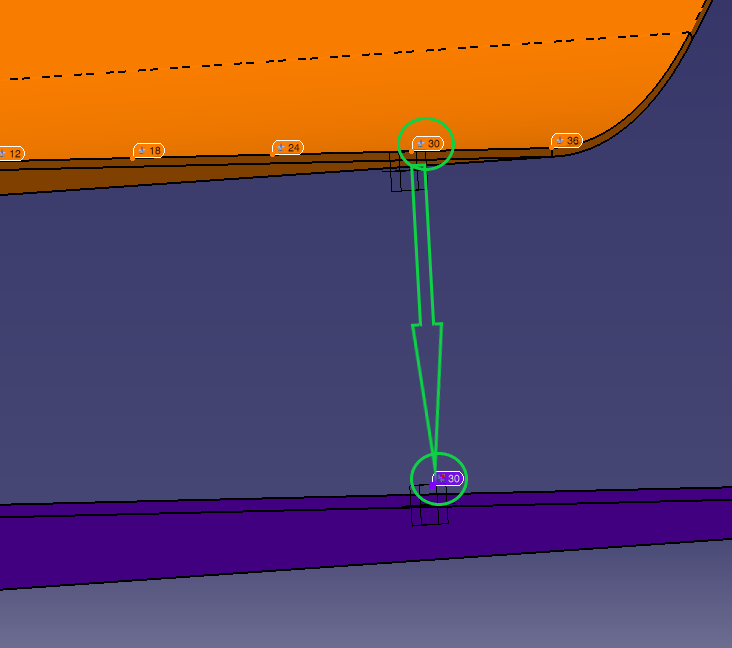

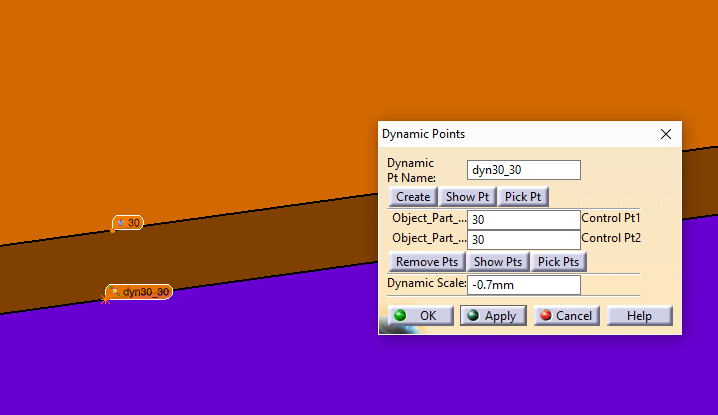

The Dynamic Point can be used as an offset point. Tolerances will need to be applied to the Feature Point or the Coordinate (DCS) Point.

Using the Dynamic Point as the Target point can be useful, as it will apply the tolerance variation to both the surface point and the Dynamic Point in the part, simulating the thickness.

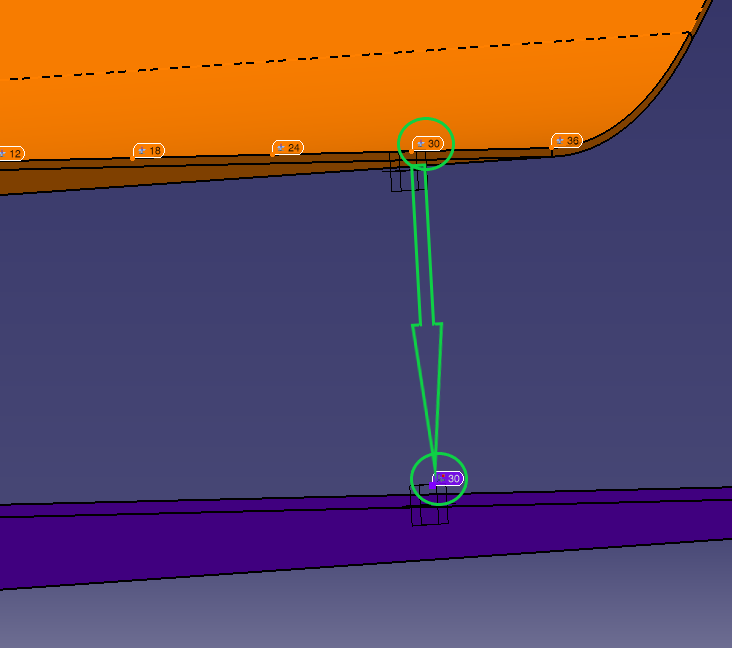

You can use this method to use the Dynamic Point as the Target Point in a move. You can still add tolerances to the surface or the Feature Point (Pt30), which will also cause the Dynamic Point to deviate with the surface tolerances.

With this process, you’re basically taking the top surface point and copying that to the object part and using it as one of the locators in the move.

You can use this method with your moves, to make the offset point (Object) to align to the target point. Then you can add tolerances to the Target point.

This routine deviates the object features based on the deviation of the target features. The deviation includes both position and size with options. This routine is a move-deviating routine, which is deviating both positions and sizes associated with object features instead of moving the components (Move Parts.)

Inputs:

Object Features: At least one object feature is required.

Target Features: At least one target feature is required.

Values:

Outputs:

Most DLLs have additional Options (Values/Constants) available. For the Copy Point Deviation DLL, it is suggested to set up the options as follows:

In summary, to simulate part thickness, there are a few ways to simulate this in a 3DCS model. Users can decide to use a DLL that will copy variation of points to another specific set of points or create and copy points to another part (not to a ghost part).

These Stories on CATIA

No Comments Yet

Let us know what you think