I recently had the pleasure of sitting down with two of DCS’ senior analysts to talk about Gear manufacturing and simulation using the Digital Twin.

Want to Listen to the Interview Instead? Click Here

I was joined by Tom Oetjens, and Sylvia Rissell, who provide modeling and analysis services to manufacturers across multiple industries and have been working to provide insight into new technology to improve the Digital Twin to better represent gear systems and assemblies.

Sylvia is an engineer at DCS using 3DCS software since 2010. Sylvia has just begun to expand her expertise with the inclusion of Gear Modeling.

Tom Oetjens, CAE Integrations Inc, has been working with DCS to incorporate his expertise in gear modeling into 3DCS Variation Analyst software. A user since the 1990s, Tom has a long history of simulation modeling with the Digital Twin.

Talking about the Digital Twin, how does 3DCS software support Gears with Digital Twin simulation?

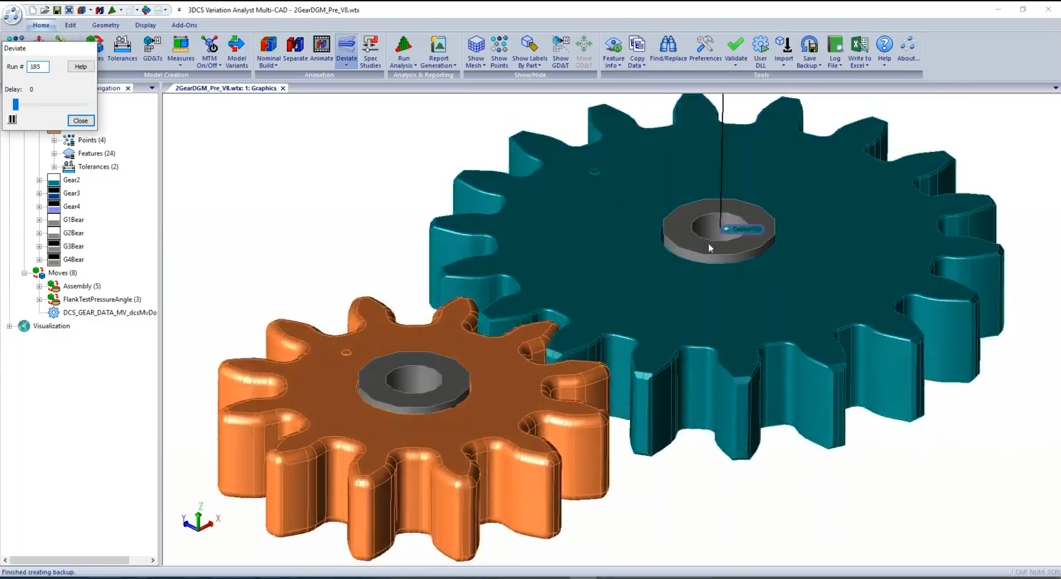

Talking about the Digital Twin, how does 3DCS software support Gears with Digital Twin simulation?Tom: When using the Digital Twin as a master, you have to have the tolerance aspect of the Digital Twin. You can’t just run it at nominal. So what 3DCS allows you to do with the Digital Twin is allow you to take the product with all its deviation and trace the effect into the gears to see how it affects the operation.

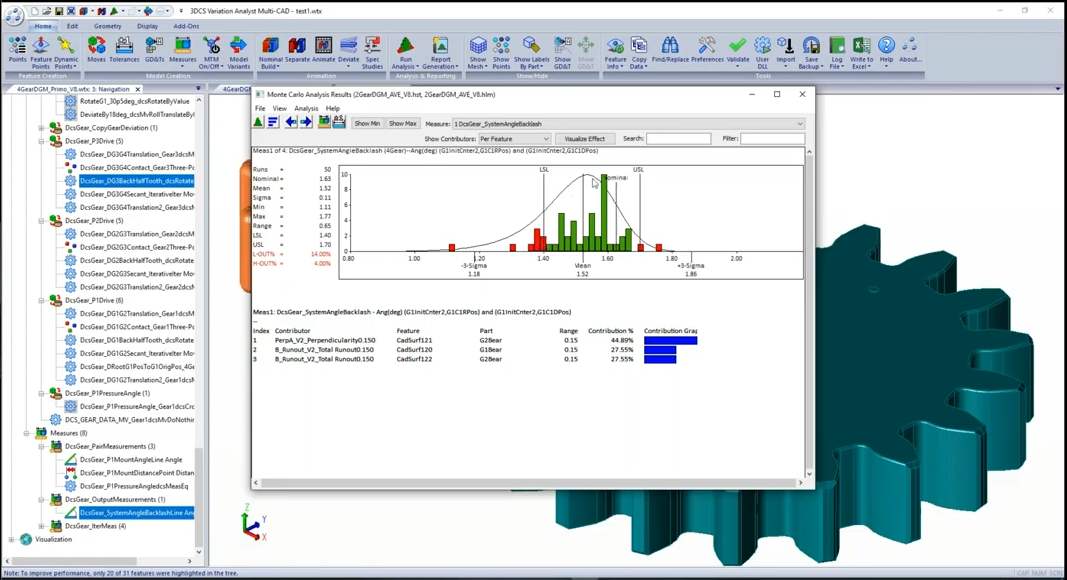

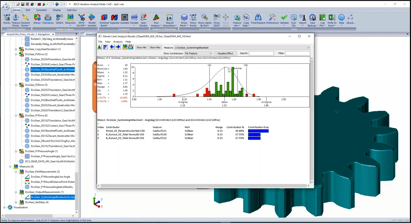

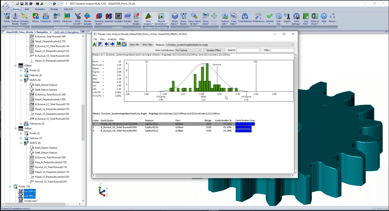

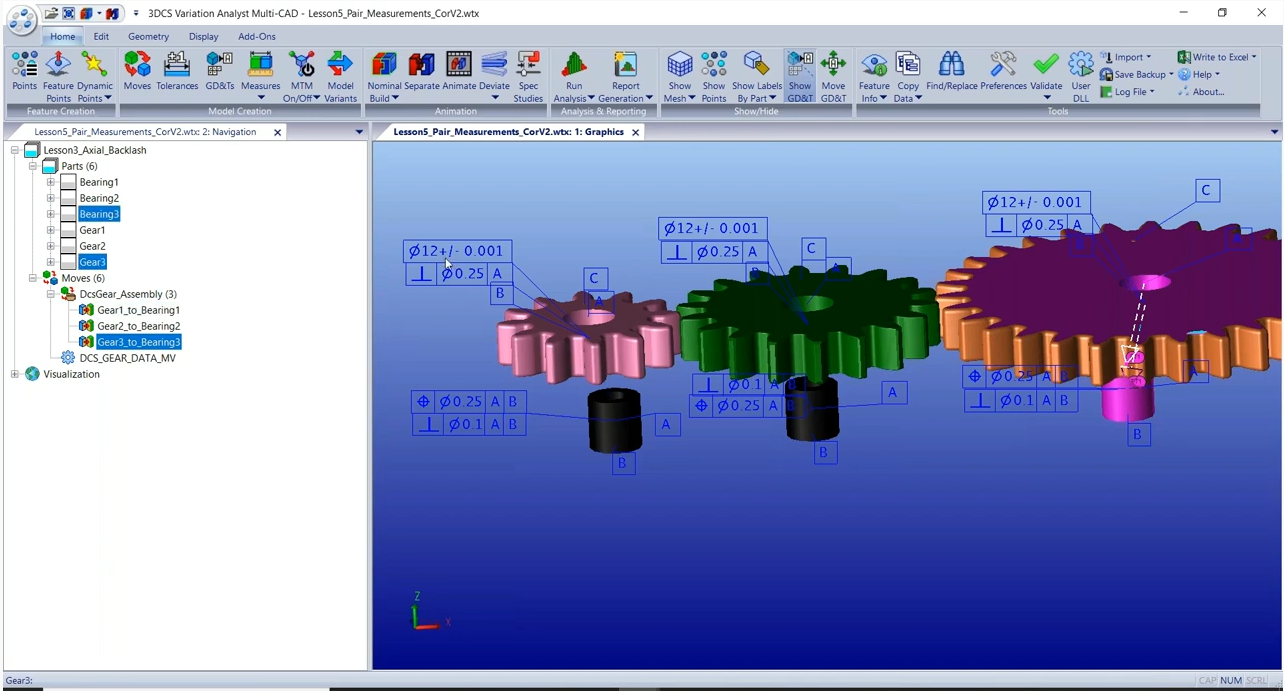

The Gear Module is a contact module. It rotates the gears to contact and then traces the contact. So you can take this contact and use it for multiple purposes. For example, there is an automatic measurement, such as backlash for angle and axial measurements, a flank pattern test, a pressure angle that traces how much the system pressurizes in terms of angle. This is the rotary angle, as the gears operating at maximum force apply pressure that pushes the gears apart. This pressurizes the whole system. So not only does the housing have an effect on the gears, but the gears have an effect on the housing. How much they push the housing apart, and how much it pushes the gears apart. It is a complete system, which 3DCS allows you to run as a complete analysis to get the statistics on the backlash, pressure angle, and look at the flank test pattern results.

Sylvia: I feel like I need to bring up Monte Carlo simulation as part of this. If we have the whole system with the GD&T and variation on all the parts, we now have the statistical variation on how you’re mounting the gears, and on the gear, which would allow us to understand what’s causing the most problems and where in order to address them.

Tom: Right, there are many things you can do with that. You can find the maximum and minimum and display the positions on the screen graphically. That’s something everyone who runs gears at high pressure wants to see, but can’t when they are inside a housing. So there is no way to see what is going on inside. The gears are of course rotating at an extremely high speed, which makes it even harder to see what is going on. With 3DCS simulation, you can x-ray it at exactly that point, at a maximum or minimum value; freeze it at that position and look at every other measurement designed in the system.

Sylvia: It is possible to do a simulated measurement on something that you can’t physically get into to measure.

Tom: So a company that is making a product with gears as an integral part of it would be a good candidate. They could take advantage of these capabilities to refine their product during the design phase. The real value can come when you’re approaching or in production and something goes wrong. If you have this modeling in 3DCS when there is a search for the cause, the exact cause, which requires a team of highly skilled experts to identify, and then the ability to try out different solutions in the digital twin to make sure they will solve the problem.

If you want excitement, that is the most exciting thing in manufacturing; when something goes wrong.

Tom: the traditional method of designing gears use a completely different system for design other than GD&T. So all the gear power companies that do the synthetic analysis and sophisticated engineering of the gears like CAE and measurements use that system to input the data, and they get outputs for machining in their own gear language which is very difficult to use by other groups. So now if you want to integrate that into your whole system it is better to convert that into GD&T, accurate CAD designs, and then use a dimensional system to diagnose and explain the issues that can now be communicated as standard information throughout the company; the manufacturing, design, and management groups.

This is because many other groups want to use the information to feed their own analyses. The gears need to be integrated into the noise and vibration unit, the dimensional engineering and drafting, the manufacturing inspections, there are a lot of communications that need to happen rapidly and completely in order to get the design correct. 3DCS can be the center and interface with everybody, as well as having its own capability in those areas.

Tom: Well, they’re not good. They can range from something that can be found and corrected in testing, which requires a lot of delay. The testing facilities, the labs are massive, and they put high pressures on the components and vehicles. These tests are expensive to operate and hard to schedule. So if you have a failure, it now affects every other part going through the lab as it delays them. You have to get everything ready, engineered, remade, and back in the lab to get tested again to work your way through what is wrong. You have equipment with microphones on it, analysis on it, spreadsheets, histories, meetings, reports, it is quite a process if something that goes wrong. Plus, there is a list of everything that is wrong, and the engineer's name is on the list and everything that’s going wrong. Then there are the top ten issues and how long you’ve been on the list.

Tom: Well the answer is what are you testing, how many gears are in it, and what do you want to find out.

So for example, you take a differential, and it is a spherical differential and it is a four gear system, which is a pretty simple system, it probably takes 3 to 4 weeks before you find everything you need to know about that digital system and correct all the errors. I haven’t seen one yet that goes through with no errors yet. There is always has something that is not quite right. It has to be corrected in the GD&T, in the parts, the clearances, in the things that would cause noise or vibration. If everything is perfect, you might be able to get it in a week and a half, but in order to fix everything, you’ll need another week and a half.

Tom: Depends on where you are looking for the value. If you are looking for value in optimization, creativity, and innovation, the earlier the better. This is because once things are set, they are almost set in stone and very difficult to change. So that is your opportunity for design.

If you are in the area of prototyping, then it is all the problems you don’t have to fix in the prototype and test shop. So that has a lot of value. If you are in production, and you’ve gone through design, the prototype, preproduction, you’ve got a lot of experience with the model, you’ve got a lot of experience with teams, so your ability to solve problems rapidly is extremely valuable because now your whole reputation of the company is on the line.

Tom: One of the best cases is, the company has a standard they are trying to meet with their gears and they have a checklist of things that have to be done. This is part of the checklist. So one thing you want to do is validate is that the conversion from the gear design module and the surfaces they produce and the conversion into GD&T and into the product are done correctly. This has to be done accurately before anything can even be started.

What you’re really doing here is finding all the errors. These could be locating errors, finding things that don’t work, finding what has to be changed. For instance, if the wrong bearing is used, 3DCS will pick it up and report it as too much angle play, your gears are tilting too much. Now you either have to fix the gears so they accept it, which can be very expensive, or change the bearings, or change the machining. That is the real value; what has to be changed and what is working properly. Knowing that off the bat or throughout the process is key.

Tom: Well, DCS has a very good service program where you can have a job in this area outlined and detailed and work with engineers to have an accurate quote developed of what it is going to take to do a specific task and get the output correct and get their engineers exposed to this. So part of it is educating the engineering and management force and getting them involved in a job or something they want to do by hiring DCS to do the service work. You can do a lot of service work to get everybody up to speed before you buy anything such as software or a gear module from DCS. Then eventually, to get the full benefits, you want to integrate the 3DCS software into the company using the service work as you are spear pointing towards the advanced work. So start simpler and work towards the full complement of capabilities, leveraging services as a tool to get inside the process.

These Stories on CATIA

No Comments Yet

Let us know what you think