Watch the Webinar On-Demand HERE:

https://mkt.3dcs.com/gear-tolerance-analysis-alignment-non-conformance-contact

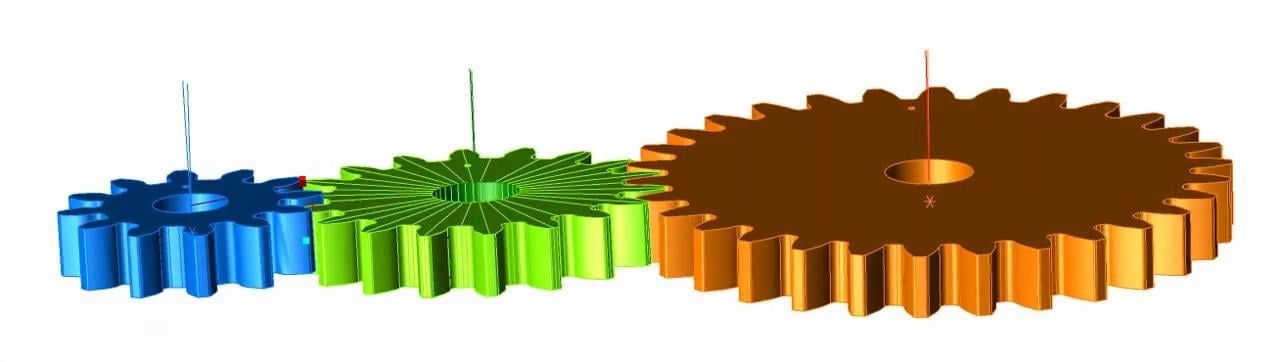

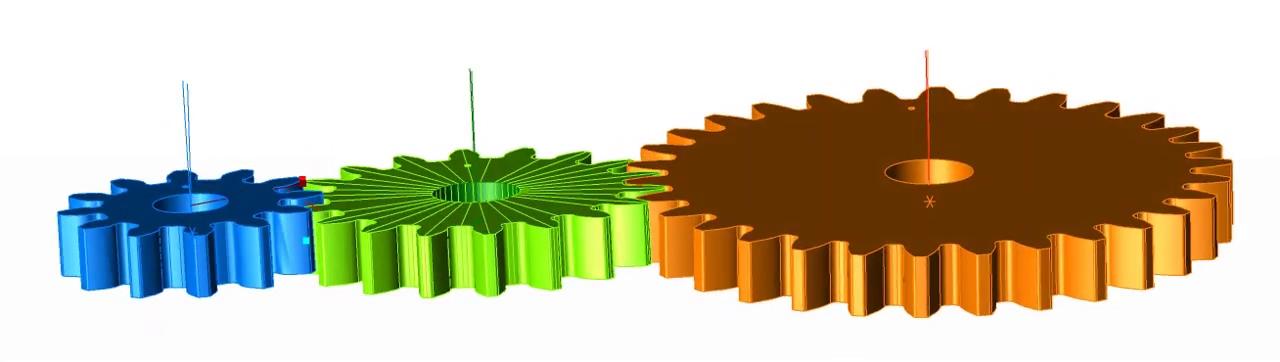

DCS hosted a webinar showcasing Gear Modeling in 3DCS software with guest Tom Oetjens, CAE Integrations Corporation. This webinar went through a standard set of gears, but the same kind of analysis can be done on a variety of gear types.

3DCS can assess gear backlash and mounting misalignments, perform angular backlash analysis, and create flank test displays and contact patterns. Here are some of the measurements it supports:

Plus, it supports both fine and coarse gear modeling, depending on the gear and business requirements.

Running a coarse study allows engineers to create models faster and validate the design intent for geometry, tolerances and measurements. This functionality can be used to eliminate infeasible models, and since the creation is fast, multiple virtual prototypes can be created and compared. The measurements at this level of functioning are only a rough estimate, but the fine study subsequently tweaks the models.

Fine study uses a full tooth contact method for highly accurate results. The additional development time and slower testing speed is required to provide the full suite of measurement and analysis tools. With a 3DCS Fine Gear Study, Engineering will be equipped to avoid misalignment and risk factors that directly impact gear performance and durability. Refining to a fine study does add to the development time and testing runs much slower, but it uses full tooth contact analysis for more accurate results.

A full suite of measurement and analysis tools is available to optimize tolerance and measurement accuracy.

Click the Image or CLICK HERE to watch the webinar

These Stories on CATIA

No Comments Yet

Let us know what you think