DCS presents e-PowerTrain Electric Motor Gear Analysis at the NAFEMS event in Troy, MI on December 7th, 2022.

NAFEMS Americas and invited speakers will cover these topics, and more, at “Simulation in the Automotive Industry: Driving Convergence to Electrification, Autonomous, and Connectivity" located at the MEC in Troy, MI. Attendees from the major automotive manufacturers and suppliers will gather at this annual event, in a pre-competitive manner, to exchange ideas, identify best practices, and drive the near-future direction of technology.

This event aims to deliver information and insights on critical topic areas in a manner that maximizes the “take-away” value for attendees. An event agenda and concept championed by several leading figures in the automotive industry will provide the opportunity to learn about the latest technologies and practices, which attendees can later share and apply within their own organizations.

Presented by Sylvia Rissell, DCS Senior Variation Analyst

The performance of an Electric Vehicle Power Unit is directly connected to critical tolerances. Tolerances drive opportunities for performance enhancement and cost reduction. The use of Dimensional Variation Analysis determines the critical tolerances, and showcases areas that can be adjusted without risk to the assembly.

Dimensional Variation Analysis simulates both part and process variation. This enables engineers to analyze their manufacturing process and determine how it affects both the assembly and final product functionality. The part tolerances, assembly process, and product measures are functionally transformed into the ability to predict and fix quality issues before the builds of concept, prototype, pre-production, and production. This provides an opportunity for a balanced issue resolution, innovation, and cost savings.

The upfront method illustrated in this presentation uses digital technology to create a Digital Twin as a parametric family of designs with statistical tolerances as the parameters. This Digital Twin then performs as the real-world product, allowing for testing and checks to be performed.

The traditional method of designing gears, as opposed to the Digital Twin concept, uses a different system for design other than GD&T. Gear power companies that do the synthetic analysis and sophisticated engineering of the gears such as CAE and measurements use that system to input the data, and they get outputs for machining in a gear language which is difficult to use by other groups.

In order to integrate gears into your whole system, the use of GD&T, accurate CAD designs, and then the use of a dimensional system combine to create a Digital Twin that allows multiple teams to diagnose and explain issues that can be communicated as standard information throughout the company; the manufacturing, design, and management groups. This is because many other groups want to use the information to feed their own analyses.

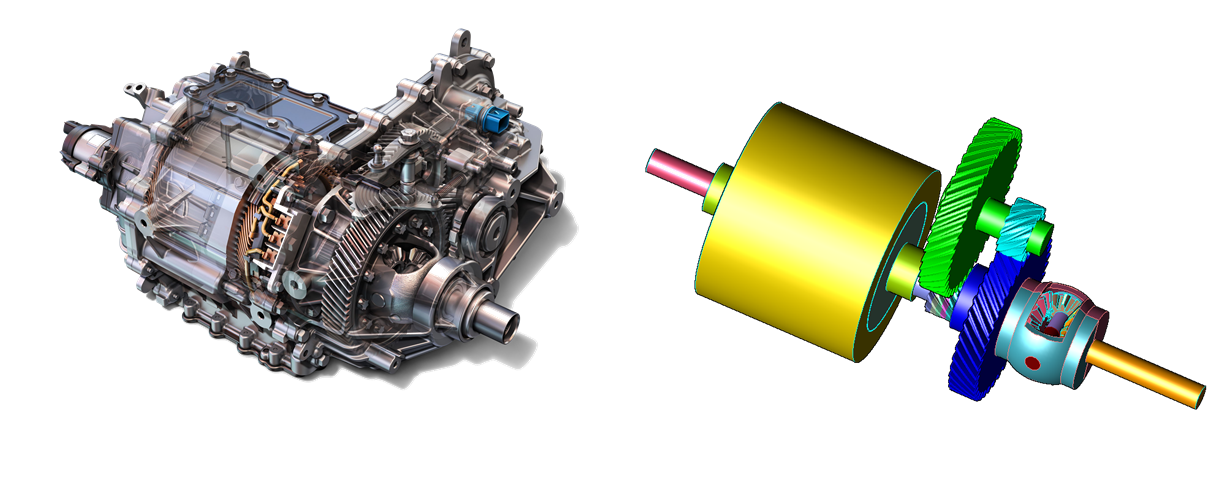

The gears need to be integrated into the noise and vibration unit, the dimensional engineering and drafting, the manufacturing inspections, there are a lot of communications that need to happen rapidly and completely in order to get the design correct. The Digital Twin can be the centre of this process, interfacing with every group, as well as having its own capabilities in those areas. Once an adjustable statistical tolerance has been established, the tolerances can be split into the individual components.

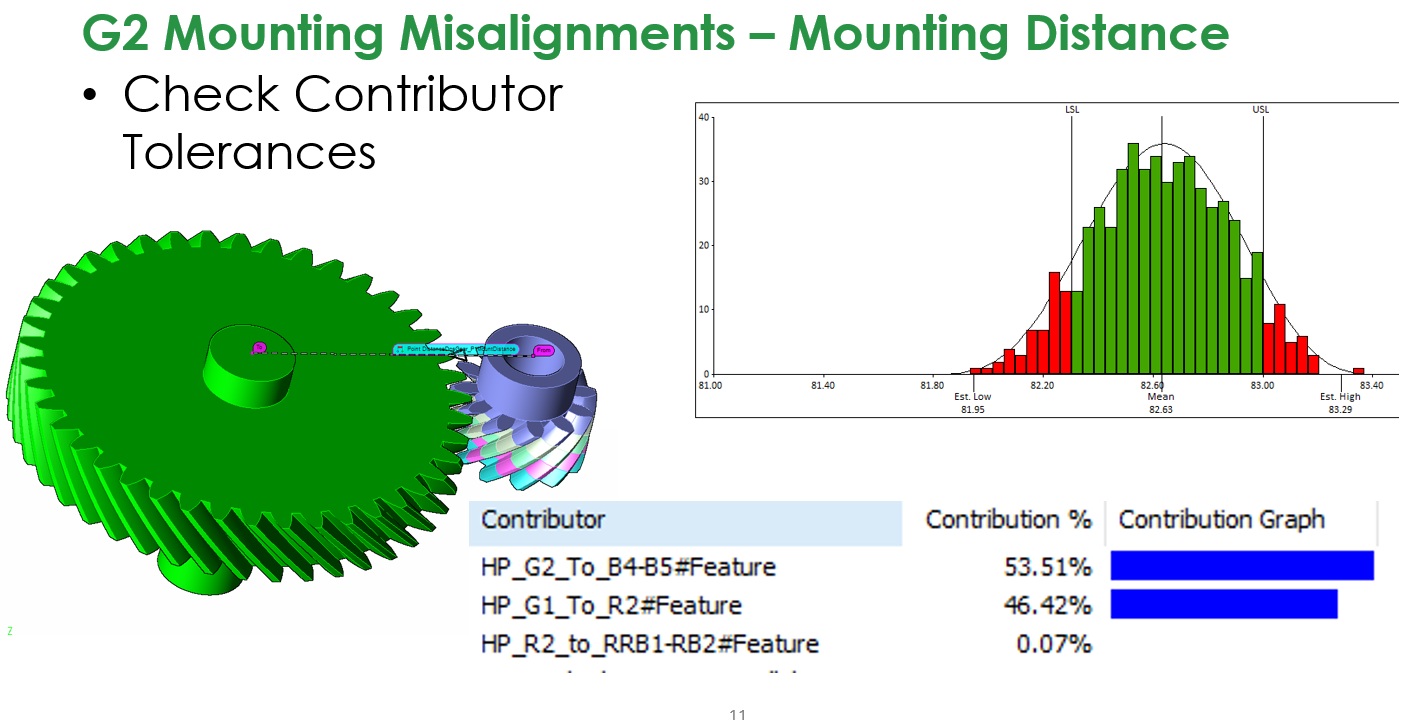

For example, in the design phase, the bearing represents the combination of the gear grade, bearing specifications, and the housing specifications. Dividing the tolerance up using statistical cost analysis can balance the design tolerances with the lowest cost. Gear micro geometry in the form of gear crowning, gear backlash, or tooth clearance is another example of the method. Adjusting the tolerance as a parameter provides the geometric information to ensure the gear system backlash and flank patterns meet the required specifications. This is done using the Contributors, the root causes of variation for a measurement. In the Contributors list, the measurements input dimensions and percentage of contribution are provided. Using this form of statistical morphing, this digital model can simulate the measurements of the final manufactured drive system as well as each component for an innovative, robust concept design or physical “mule” drivable concept vehicle.

The urgent push for a decarbonized society is certainly driving a dramatic transformation of the automotive industry, with companies totally disrupting this field and already introducing various levels of innovative technology solutions with respect to electrification, autonomy, and connectivity. Although many levels of these technologies are now on the market, their evolution is still in its infancy, with significant technical challenges ahead. Some of the major challenges include developing efficient e-motors and batteries that match the conventional ICE vehicle’s range and charging time to finally be displaced off the market. Autonomous technologies levels 1 and 2 are well established, with level 3 being introduced. However, achieving full autonomy with levels 4 and 5 still presents major challenges in terms of sensor technologies for safer and efficient road guidance as well as control systems with advanced AI integrated logics, just to mention a few!

Compounding the technology challenges, competition among established OEMs and new players in the market has become extremely intense, forcing a drastic reduction in development times to keep up with new product introductions. Furthermore, a brand-new field of innovative software features that can be sent to customers over-the-air (OTA) is being created with subscription-based options to generate additional sources of revenue. For this reason, numerical simulation now plays a major role and is being adopted as one of the main catalysts for bringing speed and efficiency to the delivery of these new technologies.

Topics presented and discussed at this conference will address various questions, such as:

These Stories on CATIA

No Comments Yet

Let us know what you think