SPC - Statistical Process Control - is not new. It has been used for decades to analyze parts and processes in manufacturing and make adjustments to reduce waste and defects. What is new are two things: the range of automation and software that supports SPC, and the ability to use it farther and farther down the supply chain. The tools are no longer massive systems that need hundreds of thousands of dollars and large teams to maintain, but Cloud based systems that can be set up quickly and used effectively, and affordably, by just a few users.

This access to SPC promises cost savings at every level of the supply chain, and at many levels that have traditionally simply dealt with quality problems as a matter of doing business.

With access to SPC available, why would you want to adopt an SPC system?

Here are five reasons why adopting an SPC system is a good idea:

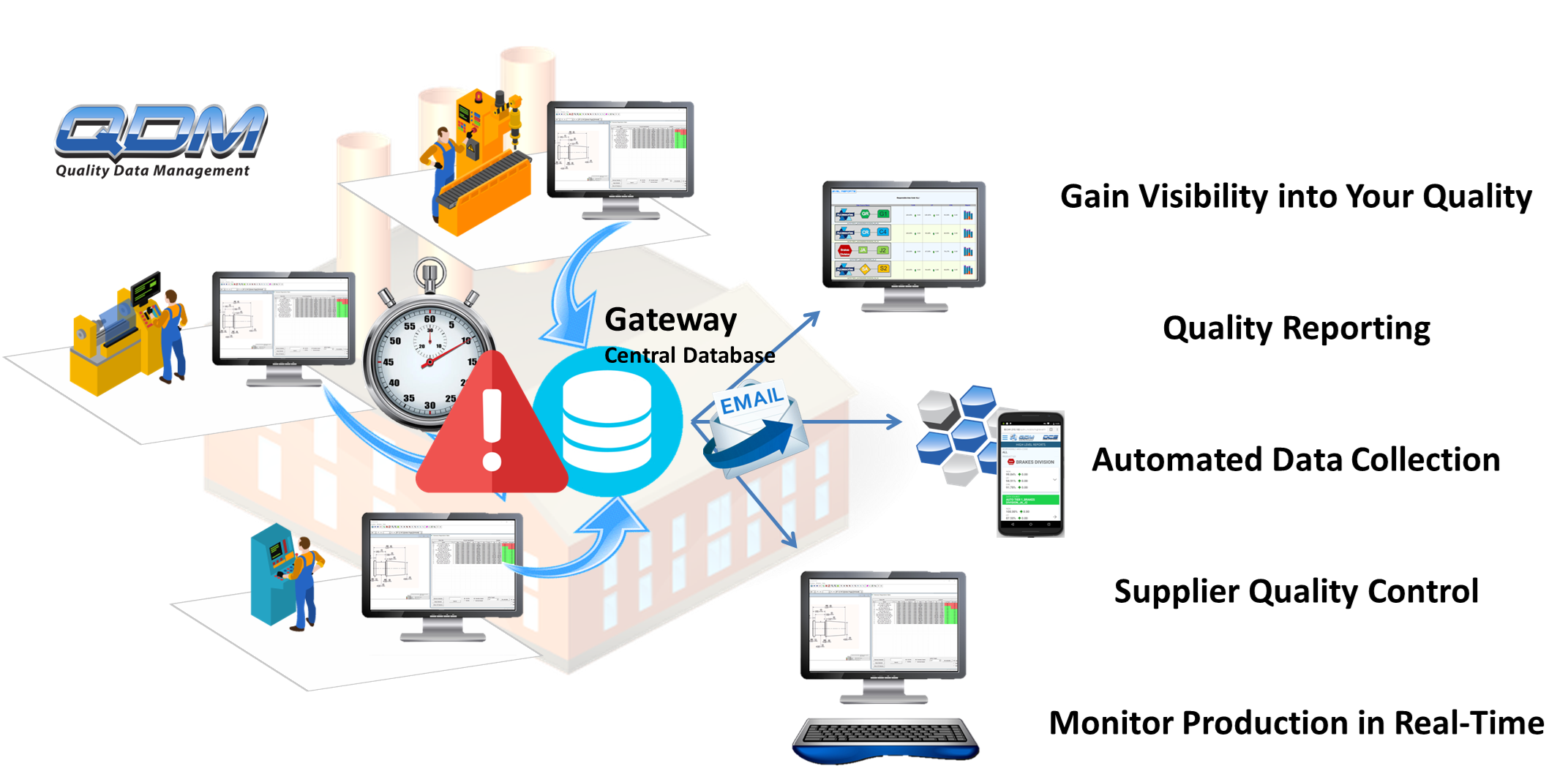

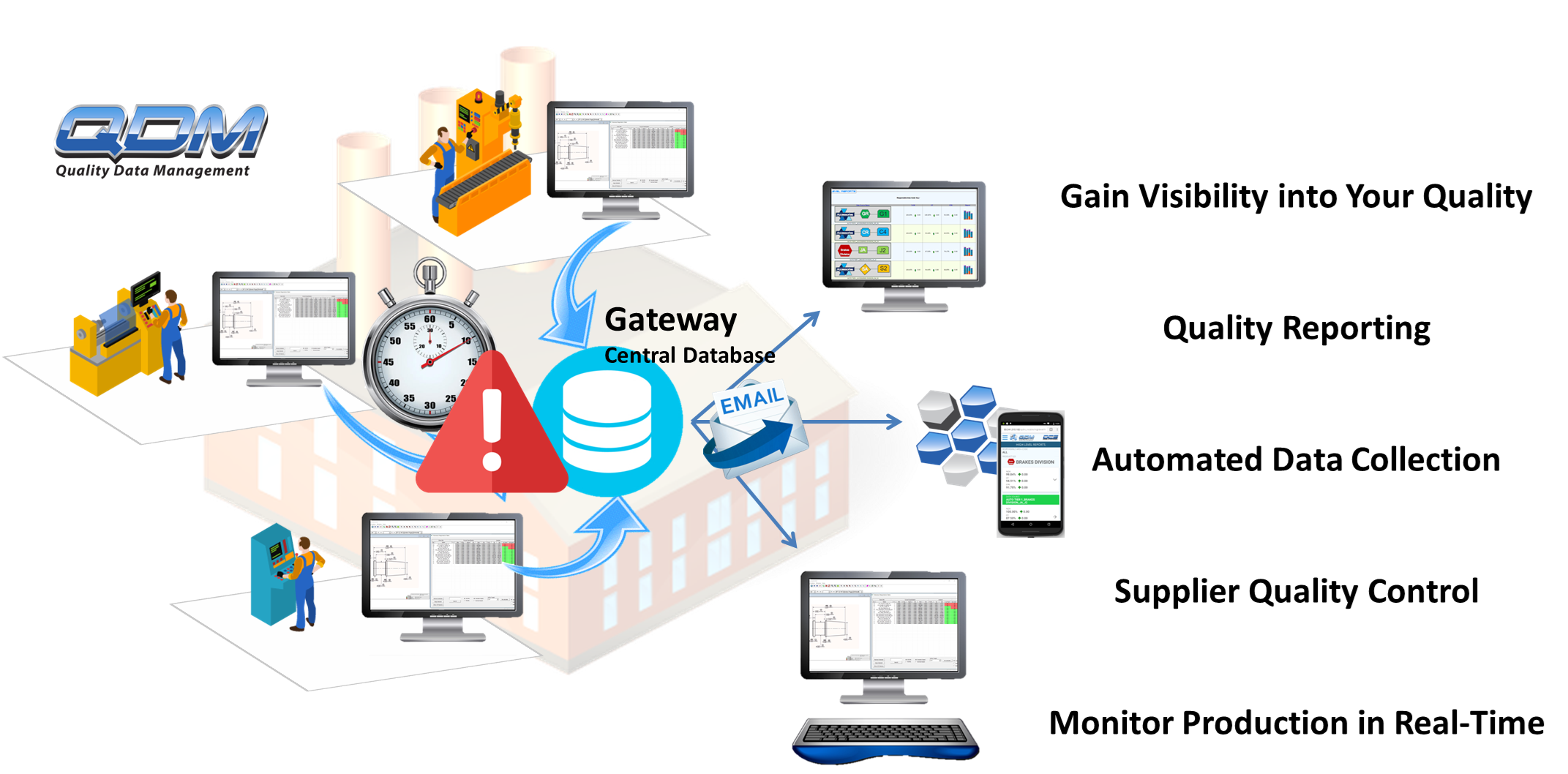

Get up to the minute information about your production: SPC metrics (Cp, Pp), measurement data, dashboards, trend charts, and other statistics as soon as parts are measured.

This keeps your operators on the plant floor up-to-date on their production quality, so that they can quickly remedy any issues as they begin to arise, as well as alerting managers and the quality team (or person in many cases) when parts begin to trend unfavorably or fail to pass inspection.

With all quality issues, the sooner you are aware of them, the cheaper they are to fix.

Get detailed quality reports in seconds instead of days or weeks so you have the information NOW when you need it, not later when problems have had time to escalate.

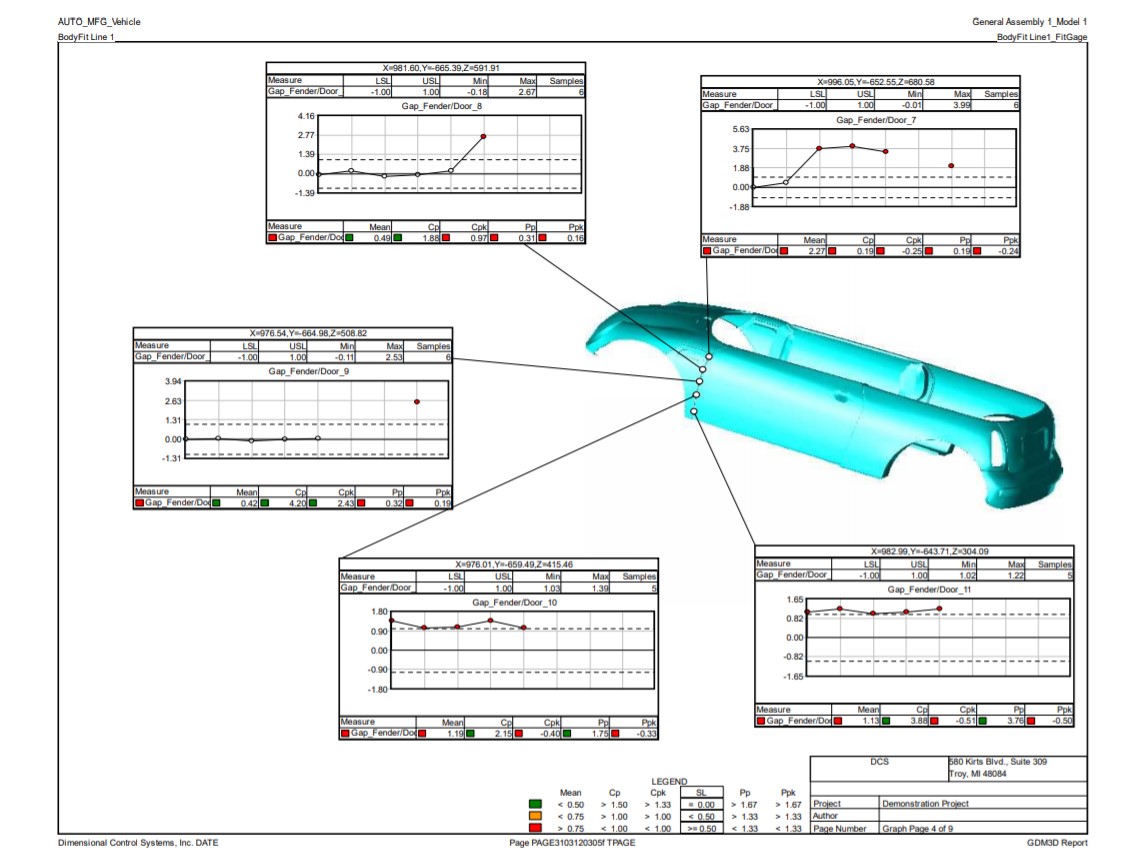

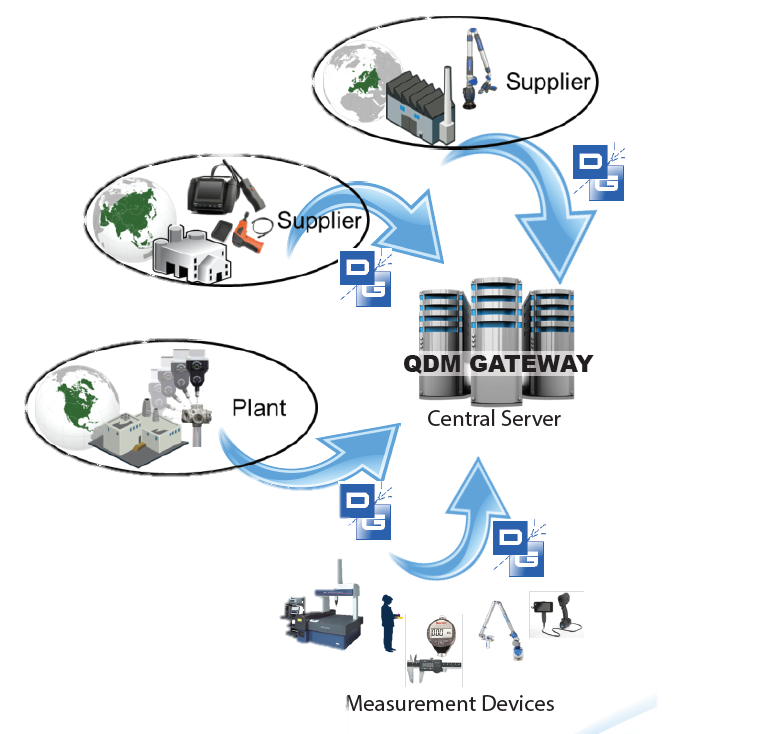

With over 400 built in translators, and a dedicated team to quickly build new ones, you can connect any measurement device from any manufacturer to your system without having to worry about special connectors, additional software, or compatibility issues.

QDM is designed to work with any measurement device, or with Excel sheets. Still using clipboards and manual hand gages? Set up a Data Entry Portal and manually input the data as its measured. The point here is simple, if you have data, there is a method available to get it into QDM SPC.

Use QDM to provide measurement plans and collect measurement data from suppliers, standardizing your supplier quality through measurement plan authoring and easy data collection. Never receive bad parts again!

Your suppliers can be connected to your system, or have a portal made available for them to upload their data. The best cases are when the suppliers have access to a reporting tool for the system, allowing them to see their measurement data in the same way their customer would, and find any issues before shipping parts or sending information out. This empowers your suppliers to find and resolve their own production issues, while also helping guarantee that you won't receive bad parts, or have to re-measure every part that comes in.

Start small, and grow the system to fit your processes and needs. Turn on and off modules, or add users as needed to have the SPC system fit you, and not force you to fit the SPC system. DCS's agile team can respond quickly to updates and changes you need to help QDM fit your unique needs.

QDM is designed for small and large manufacturers, letting the organization select the modules they need, and add new ones later on. This allows for large, multi-plant deployments, as well small, single location set ups for only a few manufacturing machines.

These Stories on SPC

No Comments Yet

Let us know what you think