Automotive and aerospace manufacturers are leading the way with the application of digital GD&T technology. Applying digital GD&T to frame rails, aircraft skins, fuselages and body in white assemblies, these manufacturers are able accurately simulate part and process variation and then take steps to control and reduce its impact on the final build.

Analyzing variation is faster and easier with access to CAD embedded GD&T

This is the general application of GD&T in a digital environment, but what are the reasons to promote using digital GD&T in the first place?

Here are three big ones:

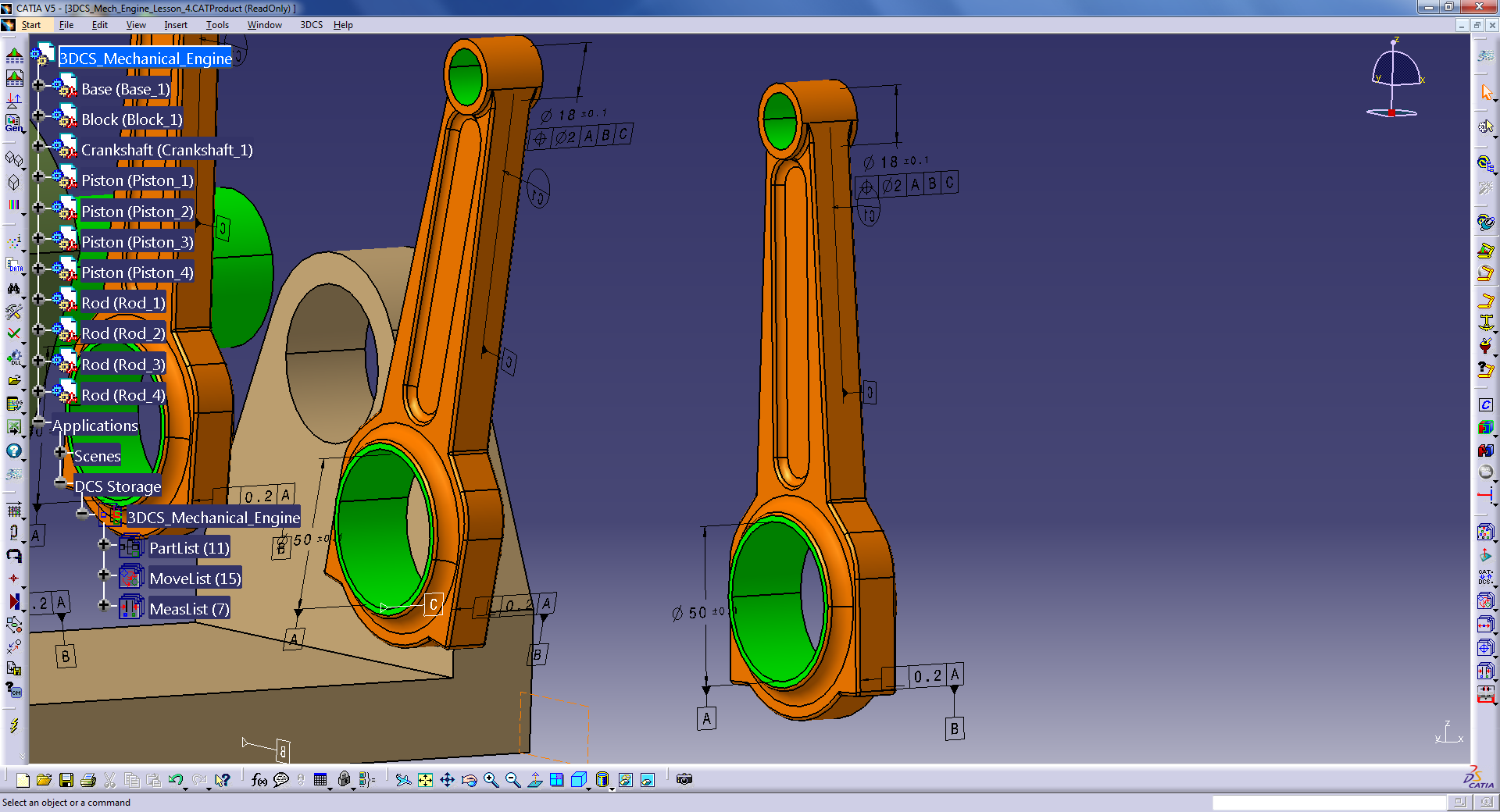

Digital GD&T streamlines the manufacturing of parts. It eliminates the need to reauthor information when performing a tolerance analysis model, eliminating errors from the design release process by giving users better control of data, and coordinates design with quality checks. Recreating each tolerance and callout in a variation model opens the door to a lot of user error. Being able to simply read in the GD&T as PMI or FTA and apply it to the model not only simplifies the process, but reduces the chance of a typo or incorrect value.

This a topic all its own, but there have been a number of innovative ideas used in industry. Hella created a program to generate tolerances and GD&T based off of ISO standards, and then used EXCEL Import/Export to update the model with the push of a button, requiring little to no authoring of data. Some companies utilize other industry standards, or pull from historical data and archived models to begin their analysis before the first draft of GD&T has been released. Once they receive the GD&T, they simply update the model and begin the process of validating and optimizing.

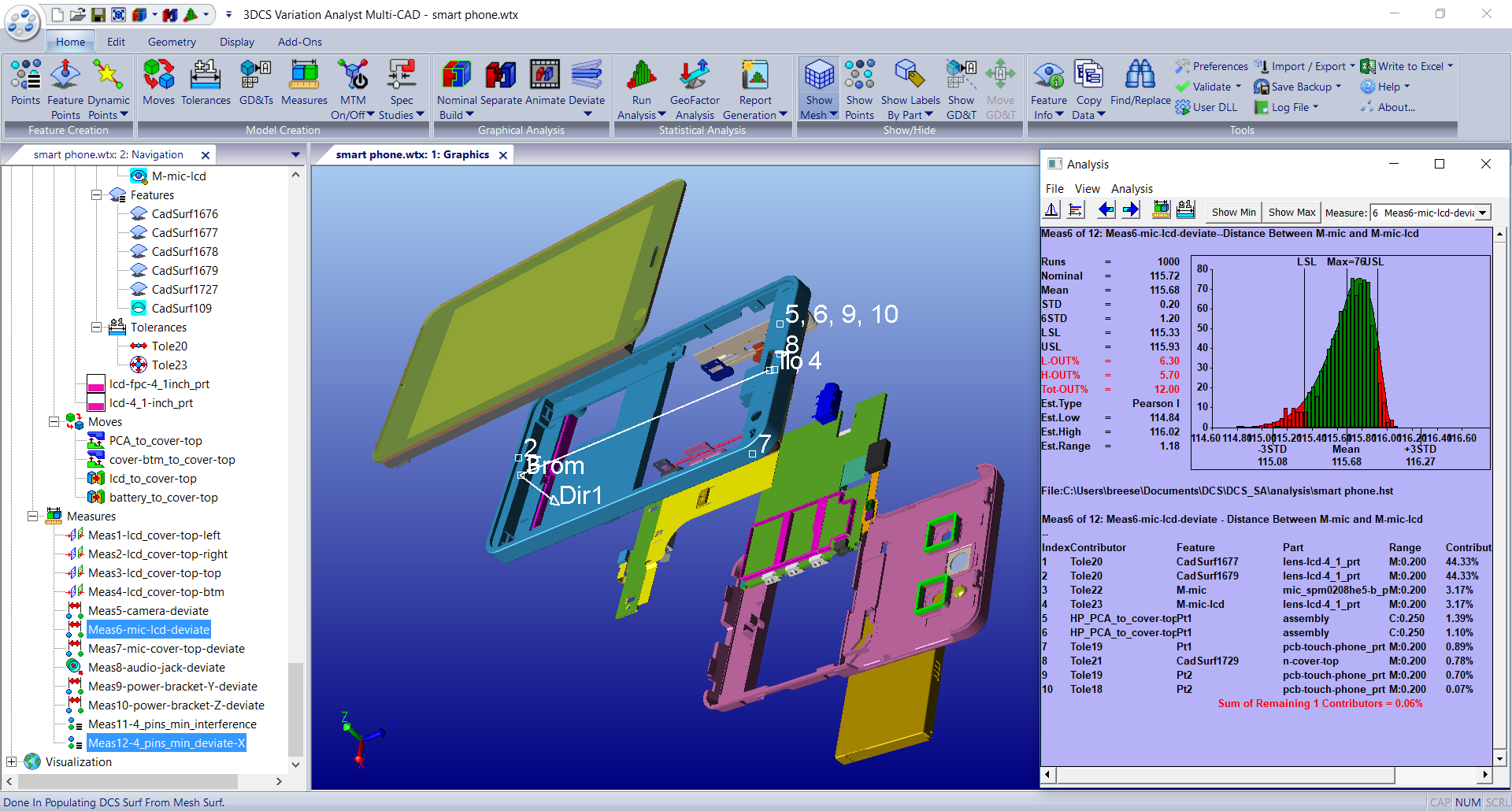

Let's be honest, you don't want to do the same thing over and over again when you can just do it once. 3DCS reads in PMI and FTA data from the CAD, as the integrated tolerance analysis software exists in the CAD platform and can use the all of the information built into the CAD model. This sets up your organization to author GD&T in the CAD model, and then apply it to a tolerance analysis model with the push of a button, saving the time it would take to reauthor that data in the tolerance analysis model, as well as, mentioned above, reducing the chance for error.

Read in PMI and FTA to instantly add it to your tolerance analysis model

That information in the tolerance analysis model can then be used to predict and verify that the part’s tolerances can meet the assembly requirements, effectively validating your GD&T and giving iterative control to optimize it for the highest quality at lowest cost. This is achieved by loosening up (increasing) non-critical tolerances to produce the product for less while still maintaining your quality goals. Because you are building the product electronically, you can catch design flaws in advance, which reduces the amount of corrections that have to be made when you go into production, saving money.

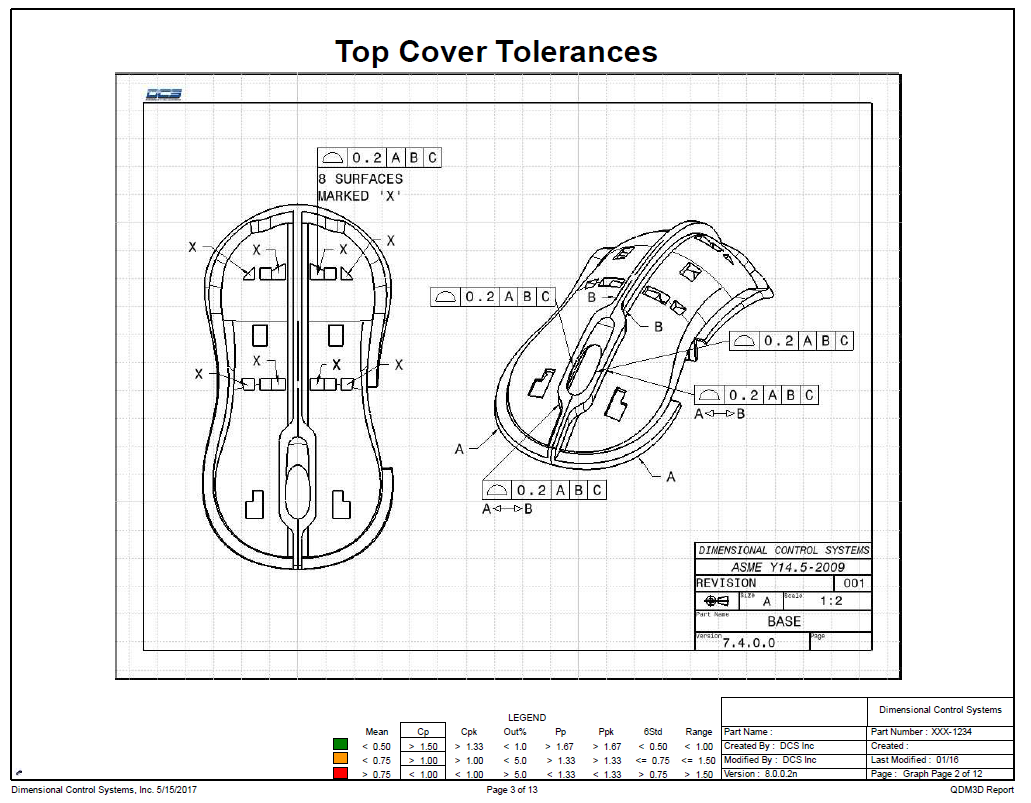

Digital GD&T can be exported from the CAD as drawings or provided as part of the model (Model Based Definition anyone?) to communicate assembly and part requirements, as well as datum and locator features, clearly communicating to both production and suppliers the specifications and the method that parts should be measured. All of this information can be done using GD&T, as being a standardized language controlled by ASME, it should leave no room for ambiguity and discretion.

GD&T drives an efficient and effective Product Lifecycle

Have you ever had parts sent from a supplier that don't match the prints? Or measurements sent from the production line measured differently than intended? Both of these scenarios can cause major headaches, and usually stem from misunderstood directions. GD&T gives clear directions on how to make the parts and how to measure them, keeping your process uniform, and your suppliers in specification. Using Digital GD&T makes it easy to communicate this information, either through a centralized and connected SPC system or via digital sharing methods (FTP or other systems...not email, right?).

GD&T gives instructions to production and suppliers on how to make and measure parts. The utilization of digital GD&T makes this information easy to communicate, analyze and optimize to improve product quality and reduce costs. Manufacturers at the forefront of this digital use of GD&T are leading the way in product quality and manufacturing efficiency.

Learn more on how to utilize your Digital GD&T at DCS' next webinar, Modeling Methods, that shows how to extract your embedded GD&T into your tolerance analysis model, and how to build up the model for iterative design

These Stories on CATIA

Comments (1)