Click Here to Watch the Webinar On-Demand

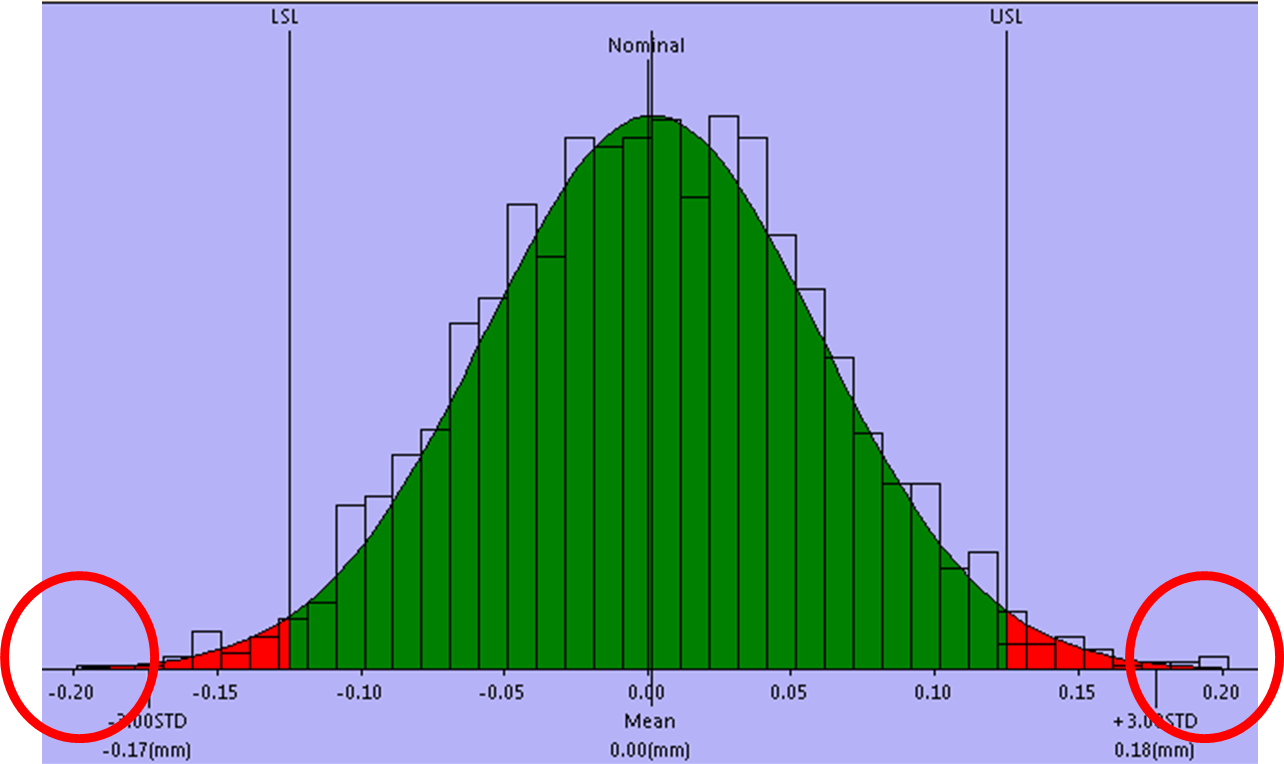

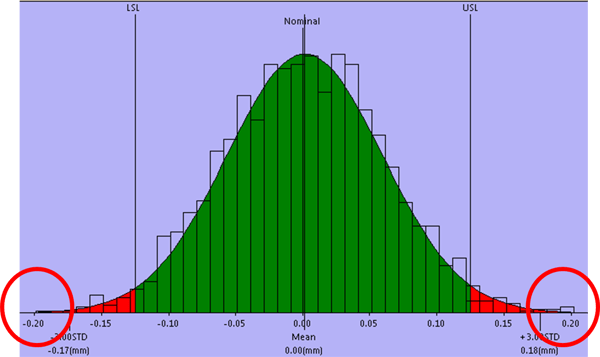

Worst Case tolerance analysis is where each individual tolerance is set to a point in its range (typically a tolerance limit) where it will result in either the maximum or minimum output at a specific measured location.

A Worst Case analysis is the only way to guarantee that an assembly of good detail parts will not be out of specification. However, in most cases, a statistical analysis gives the results needed to make decisions and reduce manufacturing costs.

Learn how 3DCS calculates, analyzes and answers Worst Case tolerance analysis.

Find out about:

These Stories on CATIA

No Comments Yet

Let us know what you think