Unlock the power of 3D CAD integrated with SPC charts to revolutionize dimensional quality analysis.

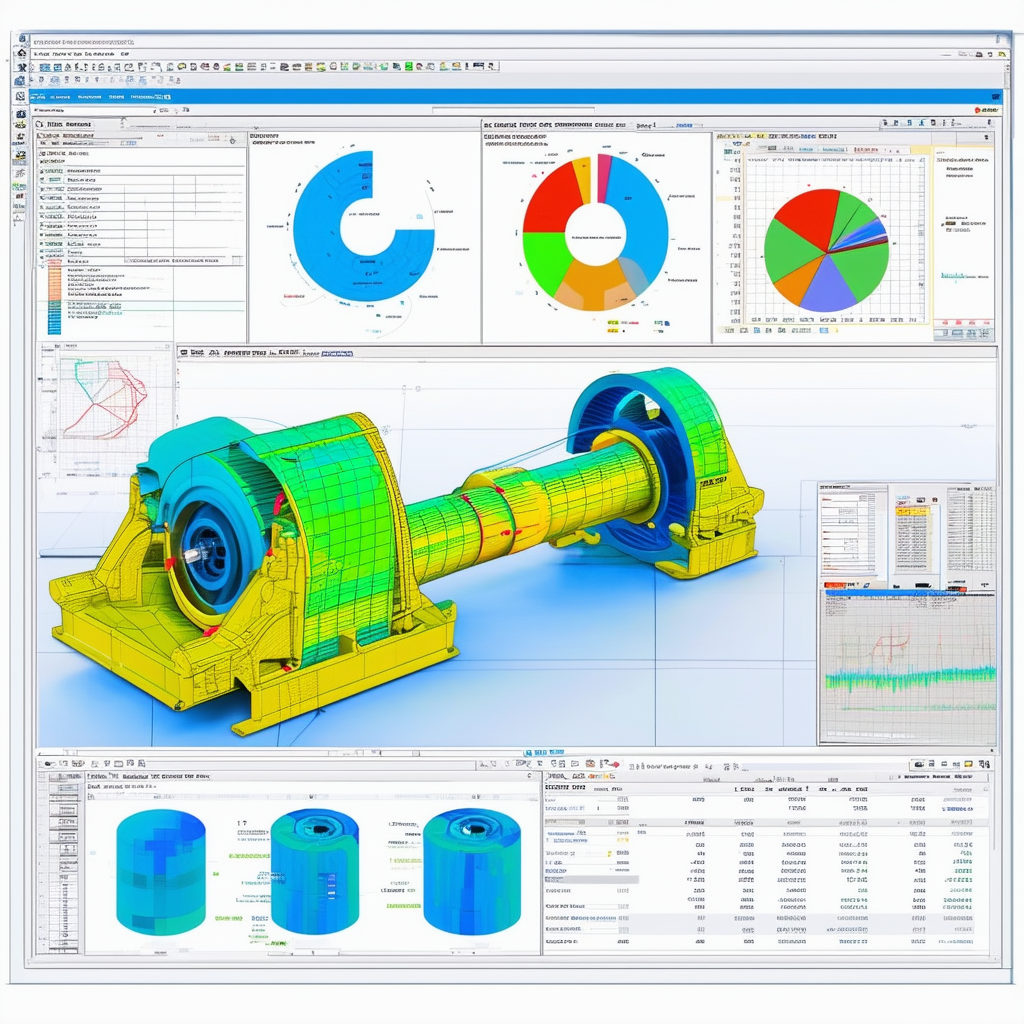

The integration of 3D CAD with Statistical Process Control (SPC) charts marks a significant transformation in the way companies handle quality control. By visualizing dimensional quality data directly on 3D CAD models, engineers can quickly identify deviations and trends that may impact product quality. This seamless integration allows for a more intuitive understanding of the data, making it easier to pinpoint potential issues before they become critical.

Furthermore, SPC charts provide real-time insights into process performance, enabling proactive adjustments. The combination of these technologies not only enhances the accuracy of quality assessments but also speeds up the decision-making process, ultimately leading to higher quality products and reduced production costs.

Web-based platforms like QDMWEB offer unparalleled advantages for quality data visualization. By hosting 3D CAD models and associated quality data on the web or intranet, companies can ensure that all stakeholders have access to the latest information, regardless of their location. This facilitates a more collaborative and efficient work environment, where updates and feedback can be shared in real-time.

Additionally, web-based solutions reduce the need for expensive on-premises hardware and maintenance, providing a cost-effective alternative. The scalability of web services also means that companies can easily expand their capabilities as their needs grow, without significant upfront investments.

One of the key benefits of 3D CAD and quality data visualization is the ability to collaborate in real-time. Quality engineers, designers, and other stakeholders can work together on the same set of data, making it easier to identify and resolve issues quickly. This collaborative approach ensures that everyone is on the same page, reducing the likelihood of miscommunication and errors.

Real-time collaboration also accelerates the problem-solving process. By leveraging browser-based tools, teams can conduct virtual meetings, share their screens, and annotate 3D models to highlight specific areas of concern. This level of interaction fosters a more dynamic and responsive quality control environment.

Localized root cause reports are essential for effective problem-solving in quality management. By using 3D CAD models, quality engineers can create detailed reports that visually represent the exact location of defects or deviations. This visual approach makes it easier for all stakeholders to understand the issue and its potential impact on the final product.

Incorporating 3D CAD into root cause analysis allows for more precise and comprehensive investigations. Engineers can simulate different scenarios, test hypotheses, and visualize potential solutions. This thorough analysis helps to ensure that the root cause is accurately identified and addressed, leading to more effective corrective actions and continuous improvement.

These Stories on SPC

No Comments Yet

Let us know what you think