The Digital Twin is a powerful tool that combines simulation, analysis, optimization, streamlined communication, and clear instructions to improve product quality while reducing manufacturing costs. That sounds amazing to managers, but anyone in engineering can tell you that actually gaining the benefits of implementing a digital transformation to use the Digital Twin is much more difficult than you’d think. A number of barriers are present at any given company, and just knowing what to do with the Digital Twin can be daunting. Let’s talk briefly about the troubles in implementing the Digital Twin, and how to get real value out of it.

The Digital Twin is a powerful tool that combines simulation, analysis, optimization, streamlined communication, and clear instructions to improve product quality while reducing manufacturing costs. That sounds amazing to managers, but anyone in engineering can tell you that actually gaining the benefits of implementing a digital transformation to use the Digital Twin is much more difficult than you’d think. A number of barriers are present at any given company, and just knowing what to do with the Digital Twin can be daunting. Let’s talk briefly about the troubles in implementing the Digital Twin, and how to get real value out of it.

When first adopting the Digital Twin, manufacturers standardize on connected CAD, PLM, and quality management systems to create the software path for the model and its contents — often encased in a QIF package — to travel through the company and be used by each group along the way. This change usually meets immediate cultural resistance as employees find themselves being forced to use all-new tools and, to make matters even worse, apply those tools in brand-new processes that feel alien to them. Once the hurdle of getting employees to use the new tools and processes is finally overcome, often at great time and expense, the people within an organization often don’t know how to apply the Digital Twin to make improvements and realize the benefits at the ground level.

So how do you get the Digital Twin up and running? First, understand that your people don’t want to change everything. Finding software tools that integrate into your existing environment and can be customized to match or mirror your current processes make the adoption task far easier. Your company has worked hard to develop internal talent on your tools, and developed processes through years of work, so don’t throw them away. Bring in tools that help you by automating your processes and streamlining your work. Secondly, bring your people into the discussion. They need to be a part of the process and understand why something new is being tried. Having everyone onboard early and feeling like they have a say in the matter will vastly improve adoption.

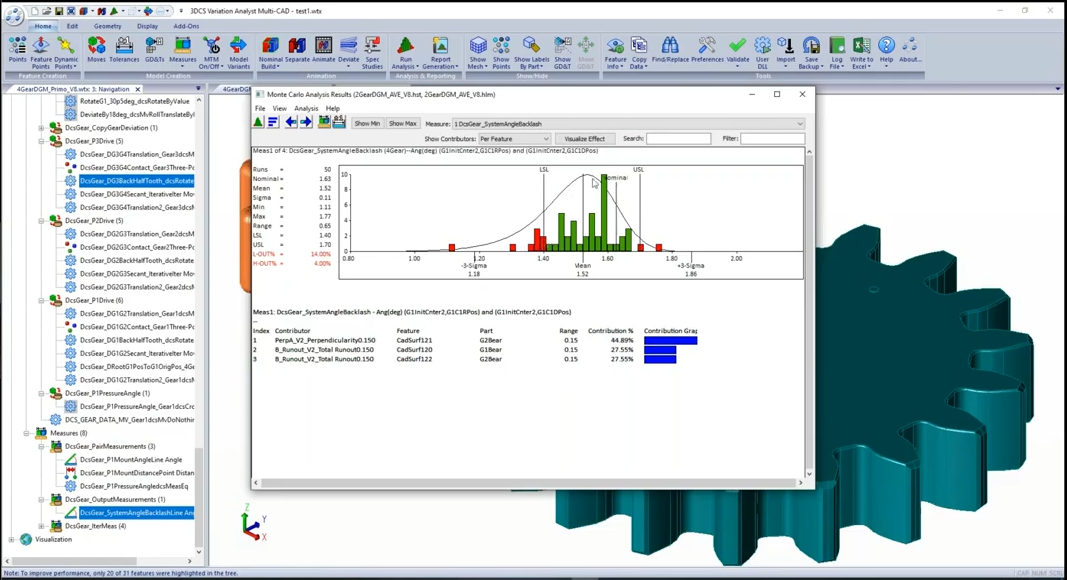

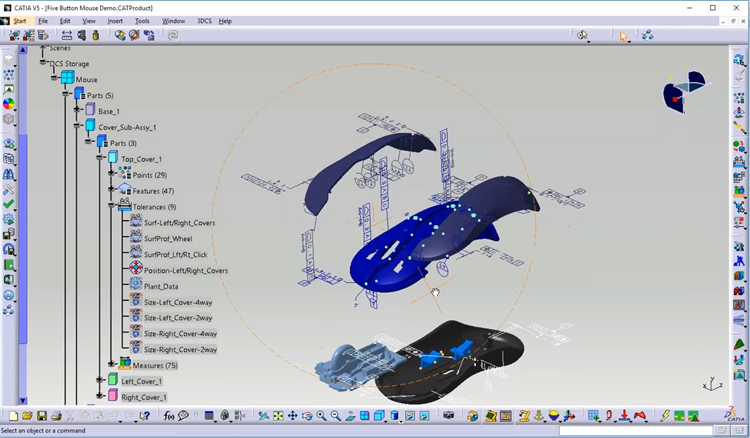

Once past adoption, how does the Digital Twin actually help reduce costs and improve quality? At the early stages of product design, while the product is still only a digital model, the Digital Twin incorporates multiple simulation tools and analyses to optimize for risk, nonconformance, manufacture, and assembly. By identifying Critical to Quality Features and modifying the design to reduce the quality in areas that aren’t functionally necessary, while tightening the design in critical areas, the risk of manufacturing defects and assembly failures can be reduced dramatically. Additionally, this informs your team on where they need to monitor and inspect in production to watch for outliers.

This is just the beginning. To learn more, visit DCS and Metrologic at IMTS Quality Pavilion Booth #135716 or online at www.3dcs.com/imts2022 to get a free quality review to learn how you can leverage the Digital Twin in your organization.

These Stories on CATIA

No Comments Yet

Let us know what you think