3DCS Sequence Optimizer quickly and efficiently finds the preferred sequence for clamping & joining parts to minimize assembly variation and process time.

Join DCS for our upcoming webinar to see how dimensional analysis and simulation can provide the results you need to determine optimal manufacturing processes.

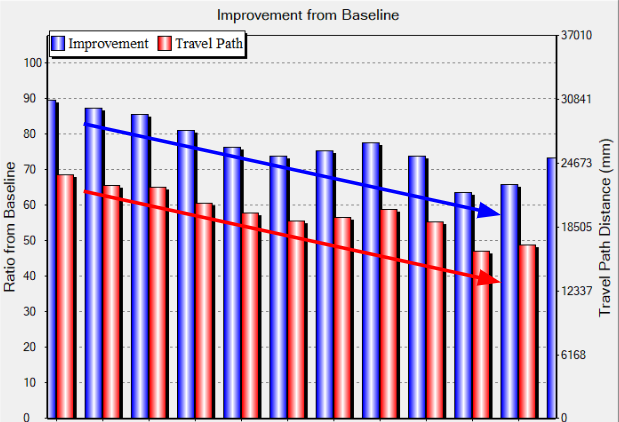

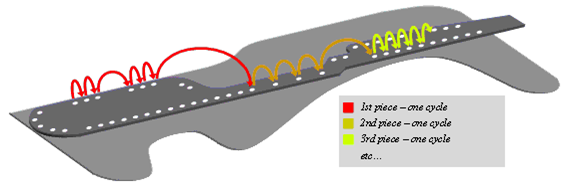

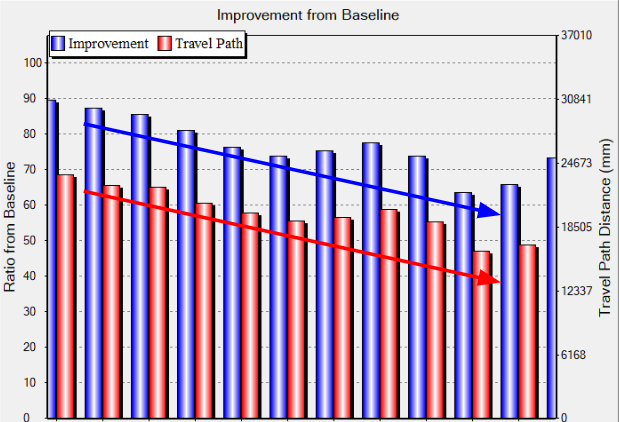

Using sequence optimization improves the overall process by optimizing the travel path as part of the sequence set. This helps eliminate the problem of optimized sequences that ignore travel path and increase the cycle time to unacceptable levels. The sequence optimization goes through iterations of optimization, improving the overall performance after each analysis. Below you can see the results from an initial study on optimizing the spot weld sequence from the image above:

The resulting process sequence provides a method for producing manufactured assemblies as close to nominal as possible given the variation from design gaps, part tolerances, and the impact of join & clamp sequences.

These Stories on CATIA

No Comments Yet

Let us know what you think