3DCS DVM (Design Variation Modeler) is an entry-level equation-based 3D assembly GD&T prediction tool integrated in the major CAD Platforms.

As an easy-to-use tool, 3DCS DVM is built around using a single multi-purpose 'move' to assemble products, and analyze in 3 dimensions. Utilizing CAD PMI to quickly build models by extracting GD&T, Moves, and Measures straight from the CAD, DVM makes modeling quick and efficient, helping you get answers you need.

Excel tolerance stacks can be helpful to get answers quickly. However, as soon as the stack includes more than a few parts, includes 3 dimensional variation, or even 2 dimensional variation, the task becomes long and time consuming. Then, when changes are made, the tolerance stack needs to be redone from the beginning.

DVM solves these problems by making initial stacks quick to build, including 2D and 3D variation, and most importantly, allowing for instant updates from design changes to see the new results.

Getting started with DVM is easy. With an intuitive interface and the ability to use CAD PMI to speed up modeling, DVM becomes a simple choice to replace Excel stack ups.

With fully integrated options, users open 3DCS DVM as another workbench within a comfortable CAD environment. This improves adoption, speeds up training, and makes using DVM simple to incorporate into existing processes.

3DCS DVM is also available as a Stand-Alone software for any CAD Platform

How easy is it to build a model in DVM? See an example created entirely from CAD PMI -->

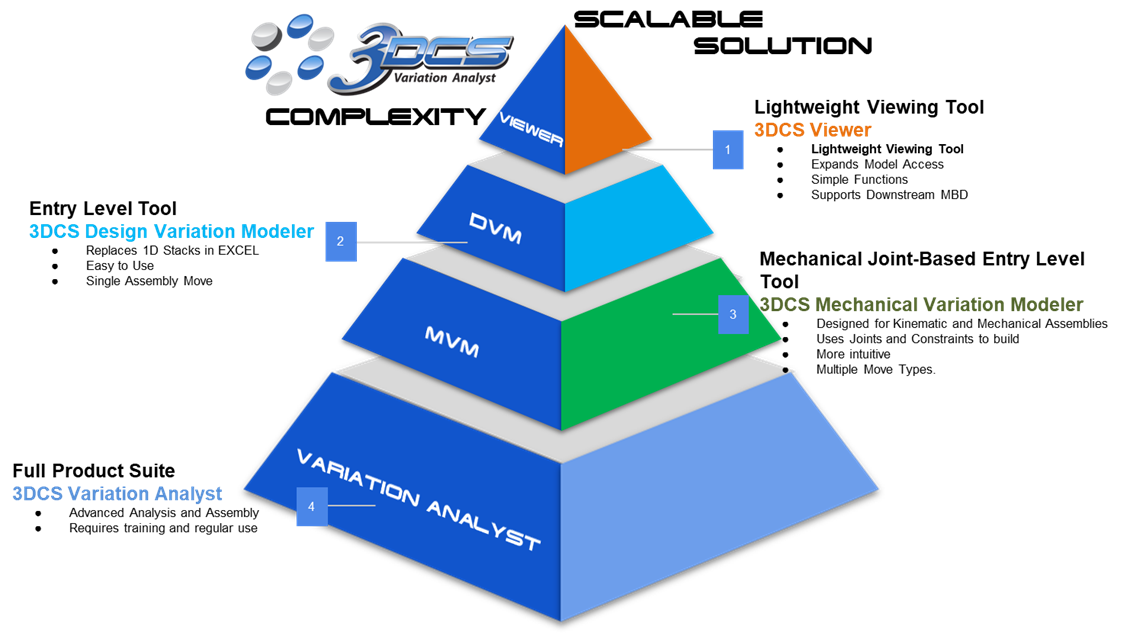

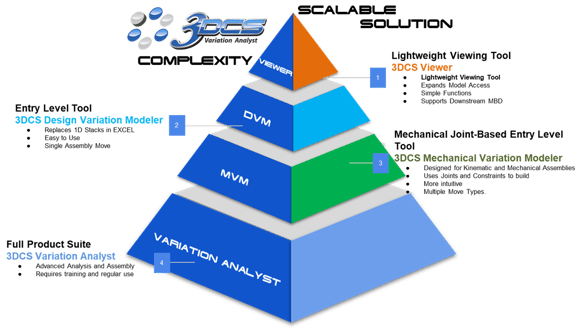

3DCS DVM is part of the DCS Scalable Solution.

This tool provides broad access to tolerance analysis for your organization, allowing for fast stacks to be calculated and tolerance models to be made quickly, with little training.

If complex processes or difficult conditions exist in your product, you can flag your models and pass them to a Specialist to use 3DCS Variation Analyst, the advanced analysis version for high complexity analysis.

These Stories on 3DCS

Comments (1)