Upcoming Webinars - Learn Advanced Skills to Improve Your Tolerance Analysis

EDIT: Links to register have been fixed

DCS's upcoming October webinars show how to use two advanced skills to improve their tolerance analysis

DCS is hosting two webinars in October to help users learn advanced skills to improve their tolerance analyses.

October 12th - Black Box Methodology -- How to use Black Boxing in your model to simplify your models and make large models load faster and run smoother. Excellent for team based modeling.

October 26th - How To Do Closed Loop Quality -- How to incorporate real data into your analysis. Find mean shifts, root cause production issues, test changes.

Working With Large Models - Black Box Methodology

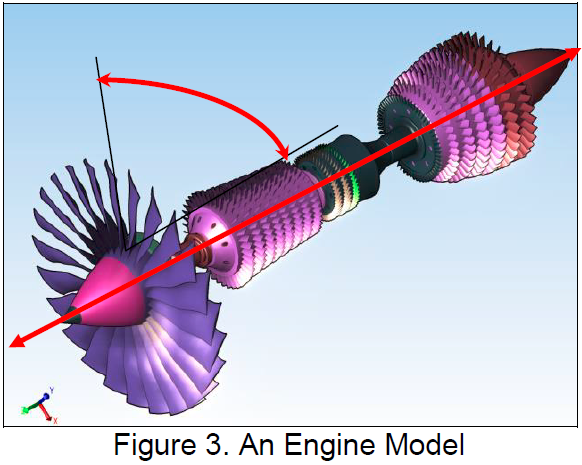

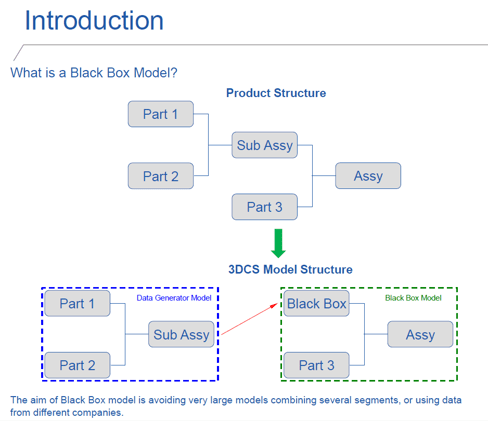

Black Box Methodology aims to turn sub-assemblies into single components when working in a model. By analyzing the sub-assembly first, the variation from that assembly can be applied to the overall assembly as a component in a larger structure, such as an aircraft.

This also helps when using data from suppliers, and in the case of 3DCS users, when using parts that may contain Compliant Components. Once the sub-assembly is black boxed, it contains the variation from its own analysis, but does not bog down your overall tolerance analysis simulation. This also removes the need to continually use Add-on module licenses when opening the model.

Advantages of Black Box:

- A big model with a lot of MTMs and a big stackup can be replaced by some points and tolerances;

- Only final results can be shared with other companies. Modeling strategy and process tolerances are hidden;

- Several Black Box Scenarios can be done based on only one model Data Generator Model run;

- Heavy FEA Compliant models can be replaced by a few points (also optimizing FEA licenses).

Disadvantages of Black Box:

- Depending on the result some curve fit must be done and some errors are generated;

- Some local datums must be created to measure the specific relationship between features;

- The original model is split, it’s necessary to manage two models;

- Some tricky higher order interaction, if not detected, can be lost;

- On the black box model, the sensitivity doesn't show the contributors (they are all bundled).

Closed Loop - Using 3DCS to Root Cause Production Issues and Manage Mean Shift

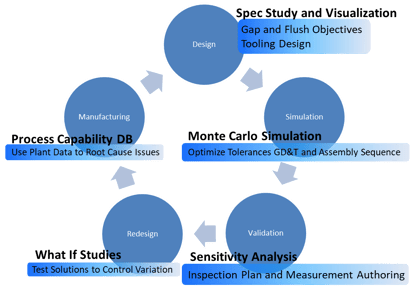

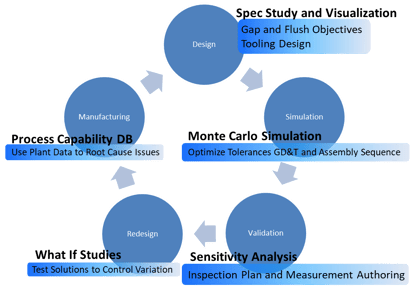

Running Monte Carlo Simulations gives a statistical understanding of what is possible, but what do you do when issues arise during manufacturing?

Closed Loop methodology is the idea of feeding measurement data from production back into tolerance analysis software to root cause and resolve production issues. This helps find the true source of the issue and then validate changes to resolve the problem.

Follow Gary Bell, DCS ASME Certified GD&T expert and Senior Variation Analyst, as he shows how to bring production data into 3DCS and see how mean shifts in manufacturing can be analyzed, how problems can be sourced and solutions validated.

Join DCS on October 12th at 11 am EST and October 26th at 11 am EST for these free webinar events.

October 12th - Black Box Methodology -- How to use Black Boxing in your model to simplify your models and make large models load faster and run smoother. Excellent for team based modeling.

October 26th - How To Do Closed Loop Quality -- How to incorporate real data into your analysis. Find mean shifts, root cause production issues, test changes.

No Comments Yet

Let us know what you think