Did you miss the last two webinars on Digital GD&T? GD&T Applications (Linear Dimensioning, Hole Patterns, FAQ) and GD&T Supporting Manufacturing (Using Plant Data in Simulation, Closed Loop) both have great information for new and experiences users of 3DCS software

|

Digital GD&T Part 2 Understanding GD&T Applications in 3DCS |

Digital GD&T Part 3 Quality 4.0 - How CAD GD&T Drives Model Based Definition with 3DCS Tolerance Analysis Software |

1. Linear Dimensioning

2. Dimensioning Hole Combinations

3. Understanding Hole Tolerances

4. Mixing GD&T and other dimensioning techniques

5. Tips for using GD&T in 3DCS

Learn how 3DCS connects processes from GD&T to measurement planning to final problem solving in production.

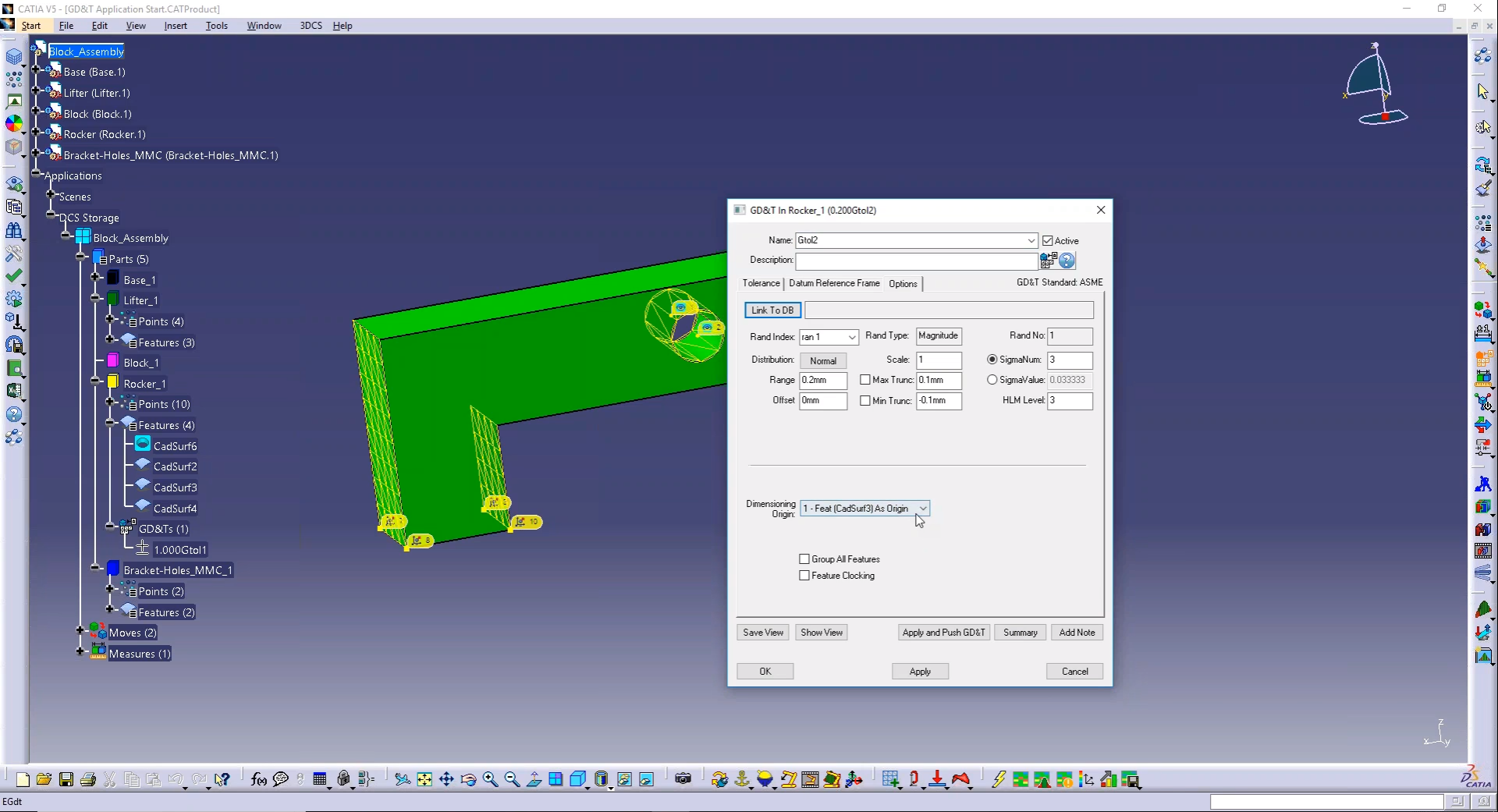

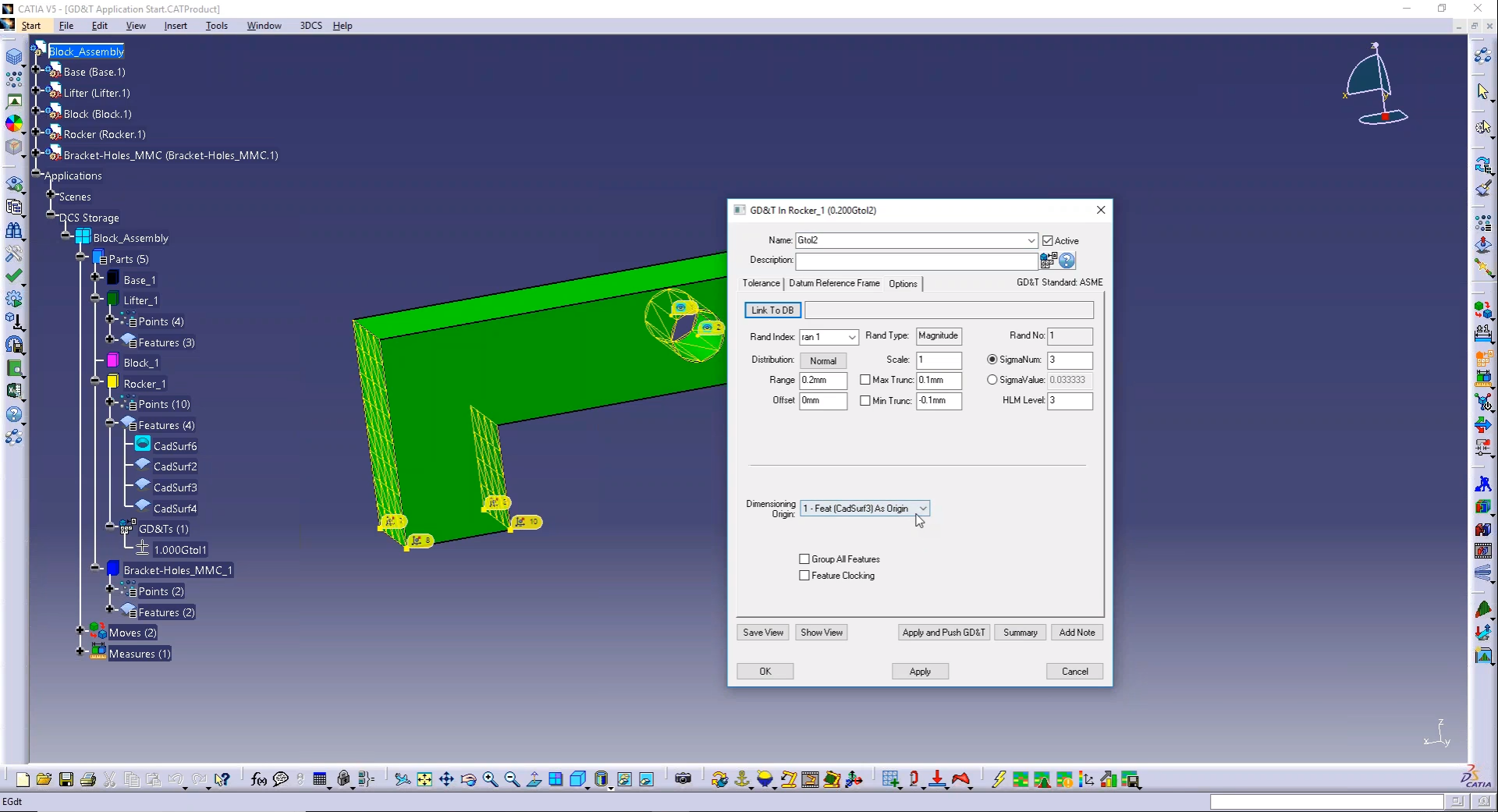

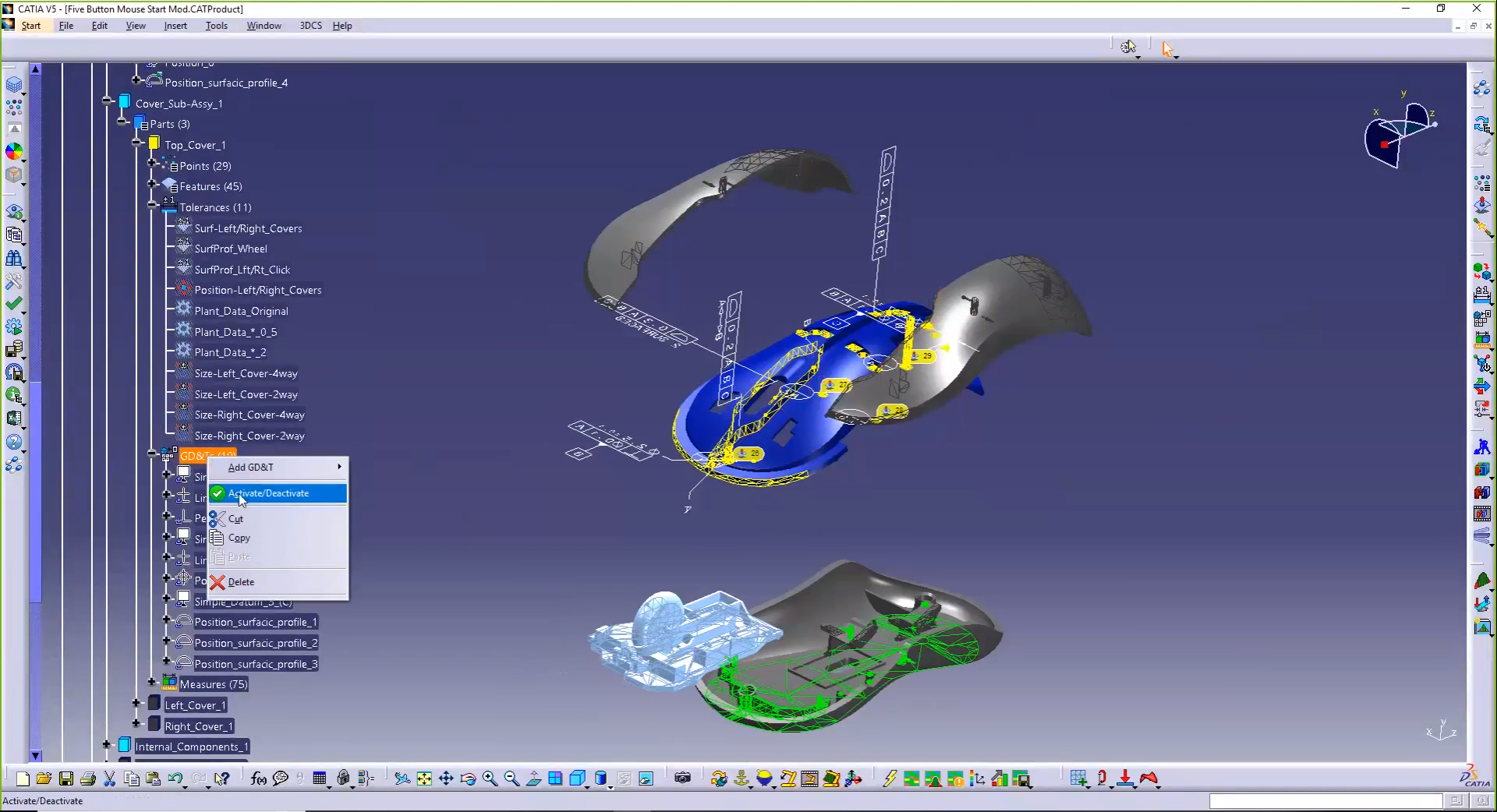

This webinar will demonstrate how to begin with GD&T and read it into 3DCS, feeding into a variation analysis model and simulation. From the simulation, measurement plans are created, with point coordination between measurement devices and the CAD model.

Once data is collected at the plant, that information can then be fed into the CAD model for determining Mean Shift, simulation to reality correlation, and root cause analysis and problem solving for manufacturing defects and assembly issues. This powerful process provides a method of interconnecting design, engineering and manufacturing through the CAD model utilizing model based definition MBD.

These Stories on CATIA

No Comments Yet

Let us know what you think