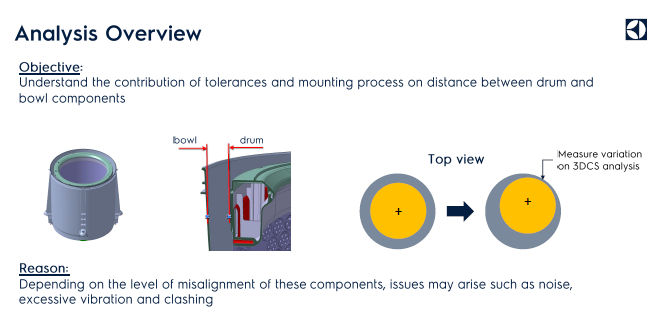

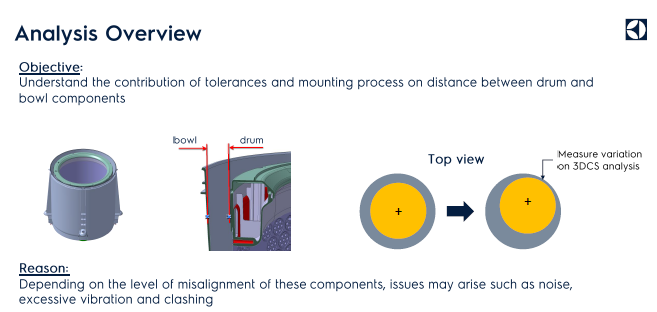

Guilherme Amitrano will be presenting his work on a drum gap analysis from Electrolux Brazil. This presentation demonstrates the modeling process of a dimensional model and shows how the results can help illustrate how the geometry of a product can magnify small amounts of variation to cause problems.

Guilherme Amitrano will be presenting his work on a drum gap analysis from Electrolux Brazil. This presentation demonstrates the modeling process of a dimensional model and shows how the results can help illustrate how the geometry of a product can magnify small amounts of variation to cause problems.

Guilherme Amitrano has been working at Electrolux since 2015, starting in Food Preparation analyzing stoves, overs, and cooking devices before moving to Fabric Care in 2018 where he has been instrumental in the analysis and optimization of products. As part of the team at Electrolux, Amitrano has always been working on research and development using 3D modeling, prototype validation, drawings, DFMEA, creating the bill of materials, and performing assembly analysis.

With any analysis tool or process change, there is always going to be skepticism. Changing from what has been traditionally viewed as 'what works' to something new and unproven in the environment is difficult.

At Electrolux Brazil, Guilherme Amitrano proved out his process, analysis, and dimensional expertise over time, showing his colleagues how valuable the outputs can be for making important design and manufacturing decisions.

See the entire presentation from Guilherme Amitrano at the DCS Global Technology Conference as he demonstrates how his analysis of a drum gap provided insight into making cost-saving design changes early in the product life cycle.

These Stories on CATIA

No Comments Yet

Let us know what you think