Discover how DCS and Capvidia are revolutionizing compliance reporting for the PPAP process with new automation technology.

The production part approval process (PPAP) is a crucial step in ensuring the quality and compliance of manufactured parts. It involves a series of documentation and validation activities that must be completed before a part can be approved for production.

DCS and Capvidia have partnered to develop a new automation technology that streamlines the PPAP process. This technology automates the generation of compliance reports, making it faster and more efficient to complete the necessary documentation.

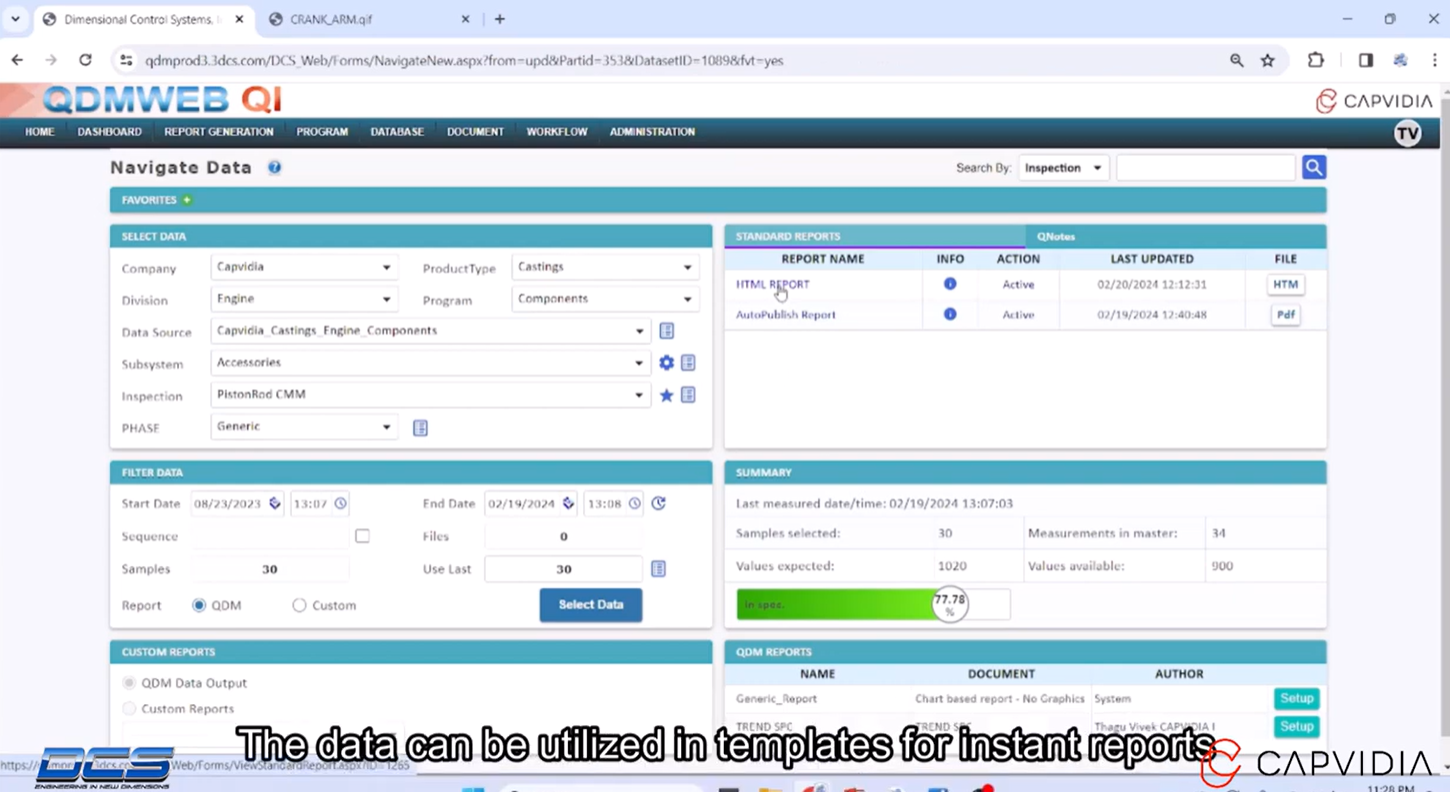

With this new automation technology, manufacturers can save time and resources by reducing the manual effort required for compliance reporting. The system automatically collects and analyzes data from various sources, such as design files, inspection reports, and test results, and generates the required compliance reports in a standardized format.

By streamlining the PPAP process, manufacturers can accelerate time-to-market for new products and improve overall operational efficiency. They can also reduce the risk of errors and inconsistencies that can occur during manual data entry and report generation.

Overall, the partnership between DCS and Capvidia aims to revolutionize compliance reporting for the PPAP process, making it easier and more efficient for manufacturers to meet regulatory requirements and ensure the quality of their products.

The automation of compliance reporting for the PPAP process offers several benefits for manufacturers.

Firstly, it improves efficiency by reducing the time and effort required to generate compliance reports. Manual data entry and report generation can be time-consuming and prone to errors. By automating these tasks, manufacturers can save valuable time and resources, allowing them to focus on other critical aspects of their operations.

Secondly, compliance reporting automation ensures accuracy and consistency in the documentation process. By automatically collecting and analyzing data from various sources, the system eliminates the risk of human error and reduces the likelihood of inconsistencies in the compliance reports.

Furthermore, compliance reporting automation enables better data management and analysis. The system can store and organize large volumes of data, making it easier for manufacturers to access and analyze information for decision-making purposes.

Overall, compliance reporting automation improves operational efficiency, reduces the risk of errors, and enhances data management for manufacturers, ultimately leading to better compliance with regulatory requirements and higher quality products.

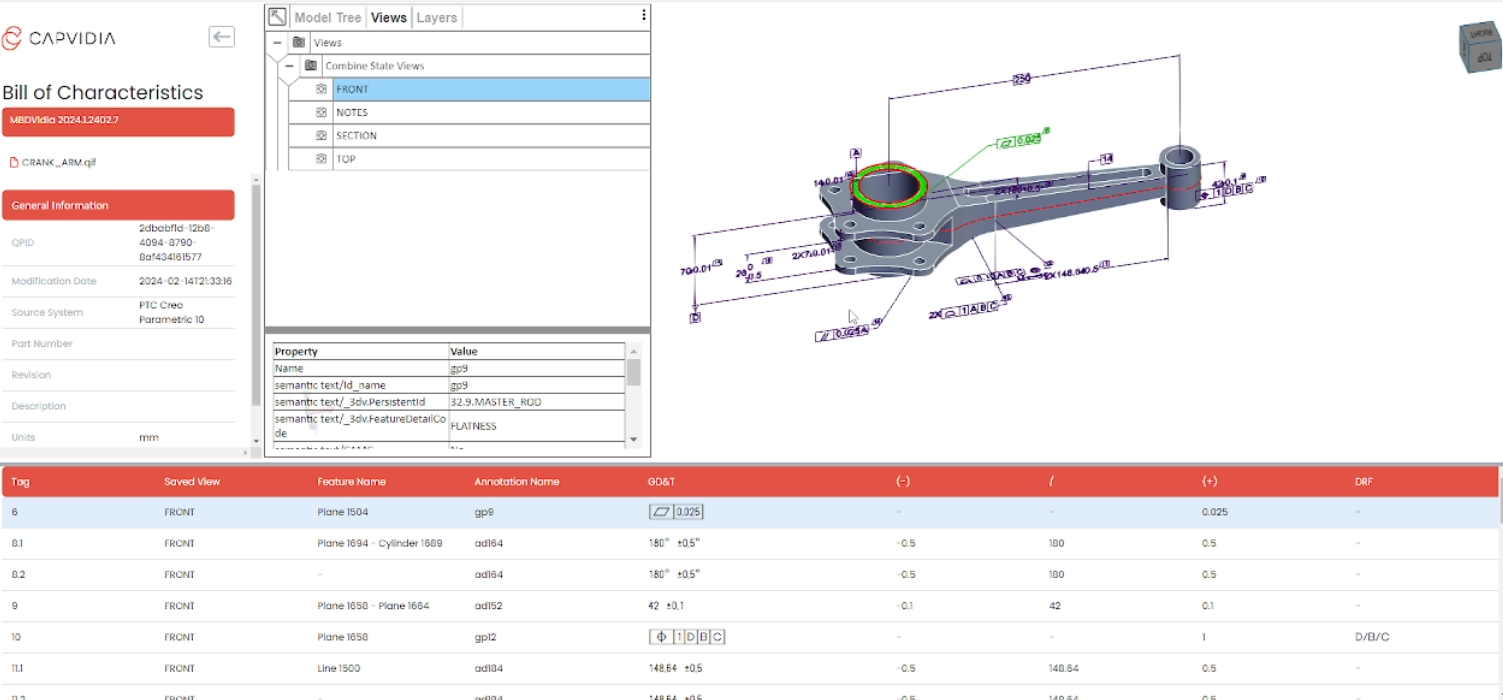

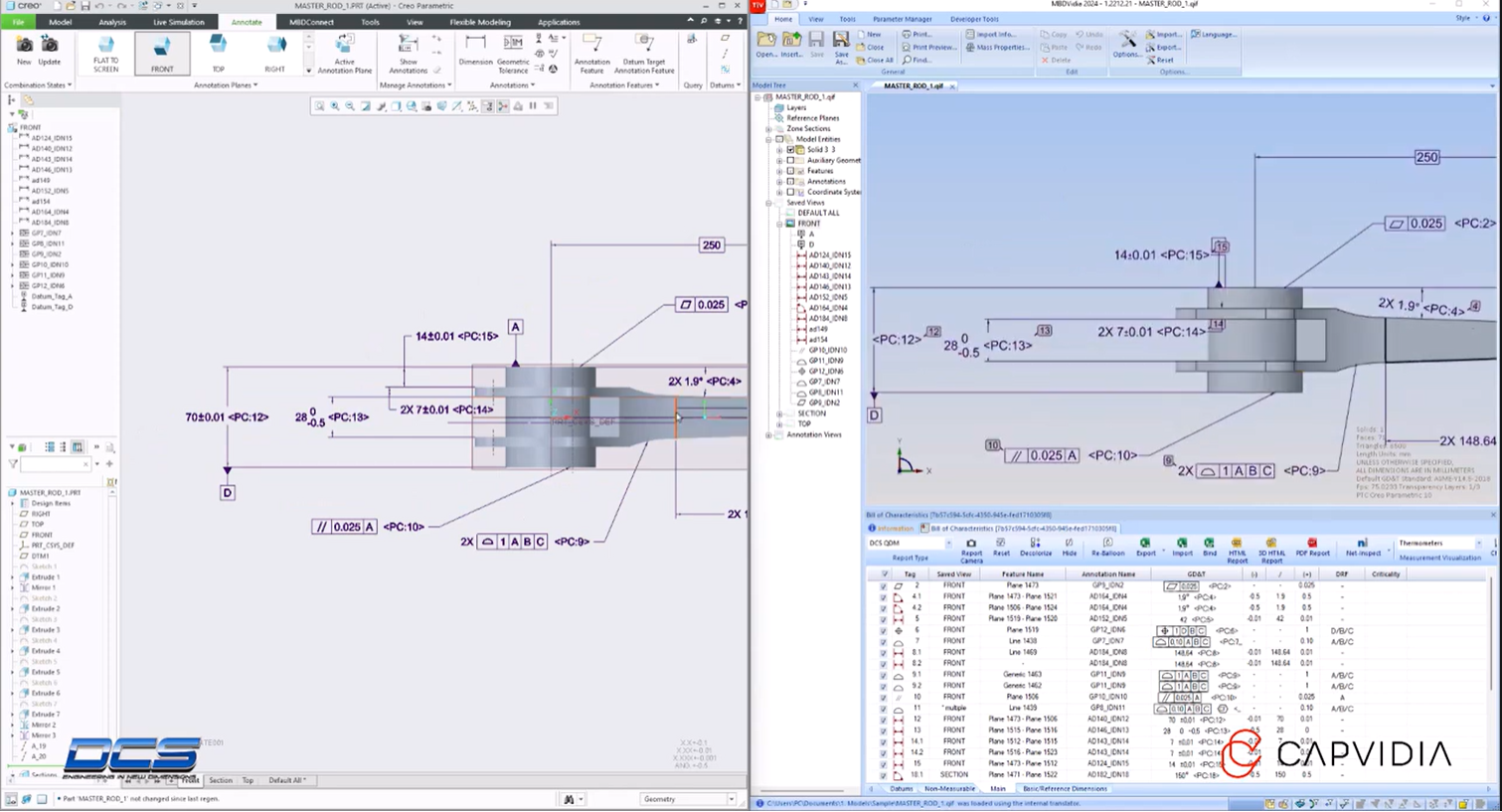

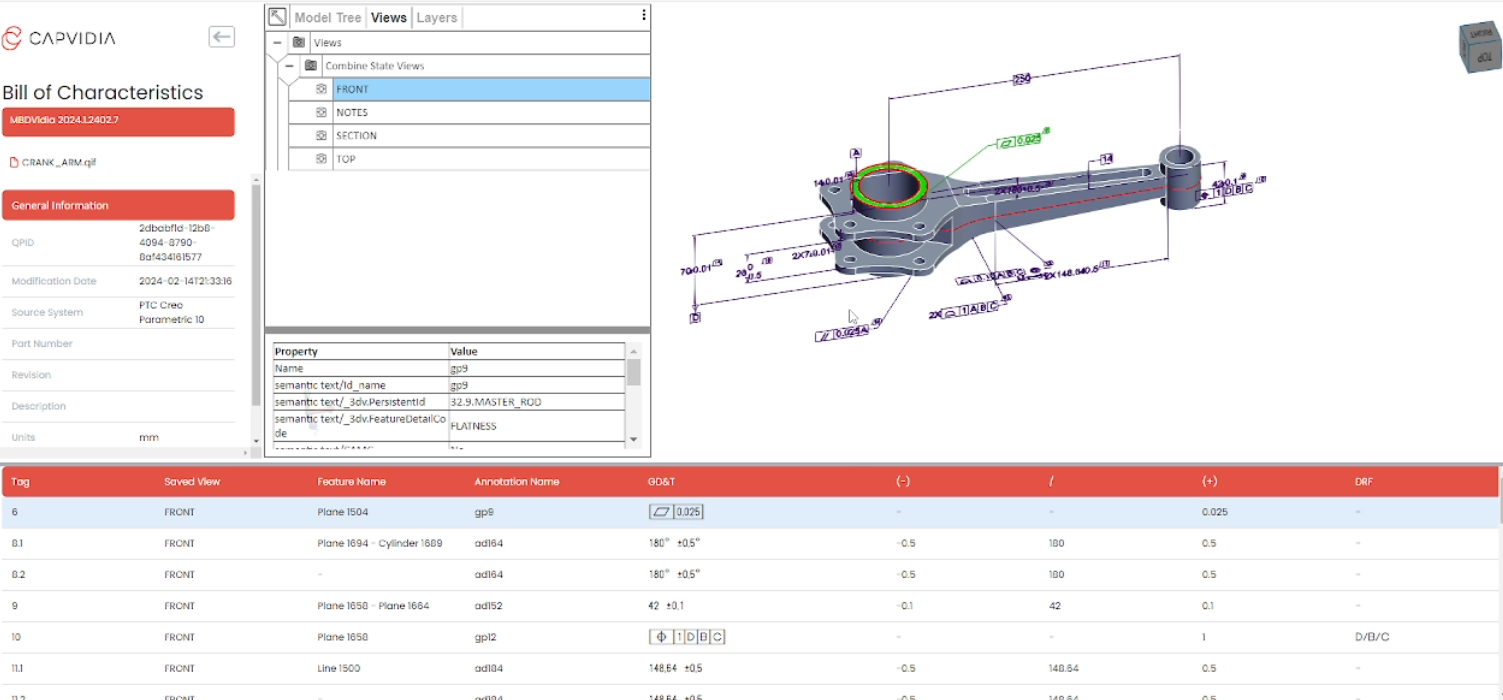

One of the key advantages of the compliance reporting automation technology developed by DCS and Capvidia is its ability to integrate with existing systems.

The system is designed to seamlessly integrate with various software applications commonly used in manufacturing, such as CAD software, inspection software, and quality management systems. This integration enables the automated collection and analysis of data from these systems, eliminating the need for manual data entry and reducing the risk of errors.

The integration with existing systems also allows for real-time data updates and synchronization. Any changes or updates made in the integrated software applications are automatically reflected in the compliance reports generated by the system, ensuring that the reports always reflect the latest information.

By integrating with existing systems, manufacturers can leverage their existing infrastructure and data sources, maximizing the value of their investments and avoiding the need for significant changes or disruptions to their operations.

Overall, the integration capabilities of the compliance reporting automation technology provide manufacturers with a seamless and efficient solution for compliance reporting, without the need for extensive system changes or manual data entry.

Accuracy and consistency are critical in compliance reporting for the PPAP process, as any errors or inconsistencies can have serious consequences for manufacturers.

The compliance reporting automation technology developed by DCS and Capvidia is designed to ensure the accuracy and consistency of the generated compliance reports.

By automating the data collection and analysis process, the system eliminates the risk of human error in data entry and calculations. It also applies predefined rules and criteria to ensure that all necessary information is included in the compliance reports and that it is presented in a standardized format.

Furthermore, the system conducts automated validations and checks to verify the accuracy and consistency of the data. Any discrepancies or anomalies are flagged for review and resolution, reducing the risk of incorrect or misleading compliance reports.

By ensuring accuracy and consistency in compliance reporting, manufacturers can have confidence in the quality and compliance of their products, and avoid potential issues or penalties associated with non-compliance.

The partnership between DCS and Capvidia aims to provide manufacturers with a robust and reliable solution for accurate and consistent compliance reporting, minimizing the risk of errors and ensuring compliance with regulatory requirements.

The future of first article inspection (FAI) and PPAP compliance is moving towards increased automation and digitization.

As technology continues to advance, manufacturers are increasingly adopting automation solutions to streamline their processes and improve efficiency. Compliance reporting automation, such as the technology developed by DCS and Capvidia, is a prime example of this trend.

In the future, we can expect further advancements in compliance reporting automation, including integration with emerging technologies such as artificial intelligence and machine learning. These technologies have the potential to further enhance the accuracy, speed, and intelligence of compliance reporting processes.

Additionally, the digitization of compliance documentation and reporting is expected to continue. As more manufacturers adopt digital systems for data management and reporting, the reliance on paper-based documentation and manual processes will decrease.

Overall, the future of FAI and PPAP compliance is headed towards a more automated, digitized, and intelligent approach. Manufacturers who embrace these advancements will be better positioned to meet regulatory requirements, ensure the quality of their products, and stay competitive in the evolving manufacturing landscape.

See the solution here:

These Stories on CATIA

No Comments Yet

Let us know what you think