Presented at Aerodef 2016 by Donald Jasurda, Vice President Sales, DCS

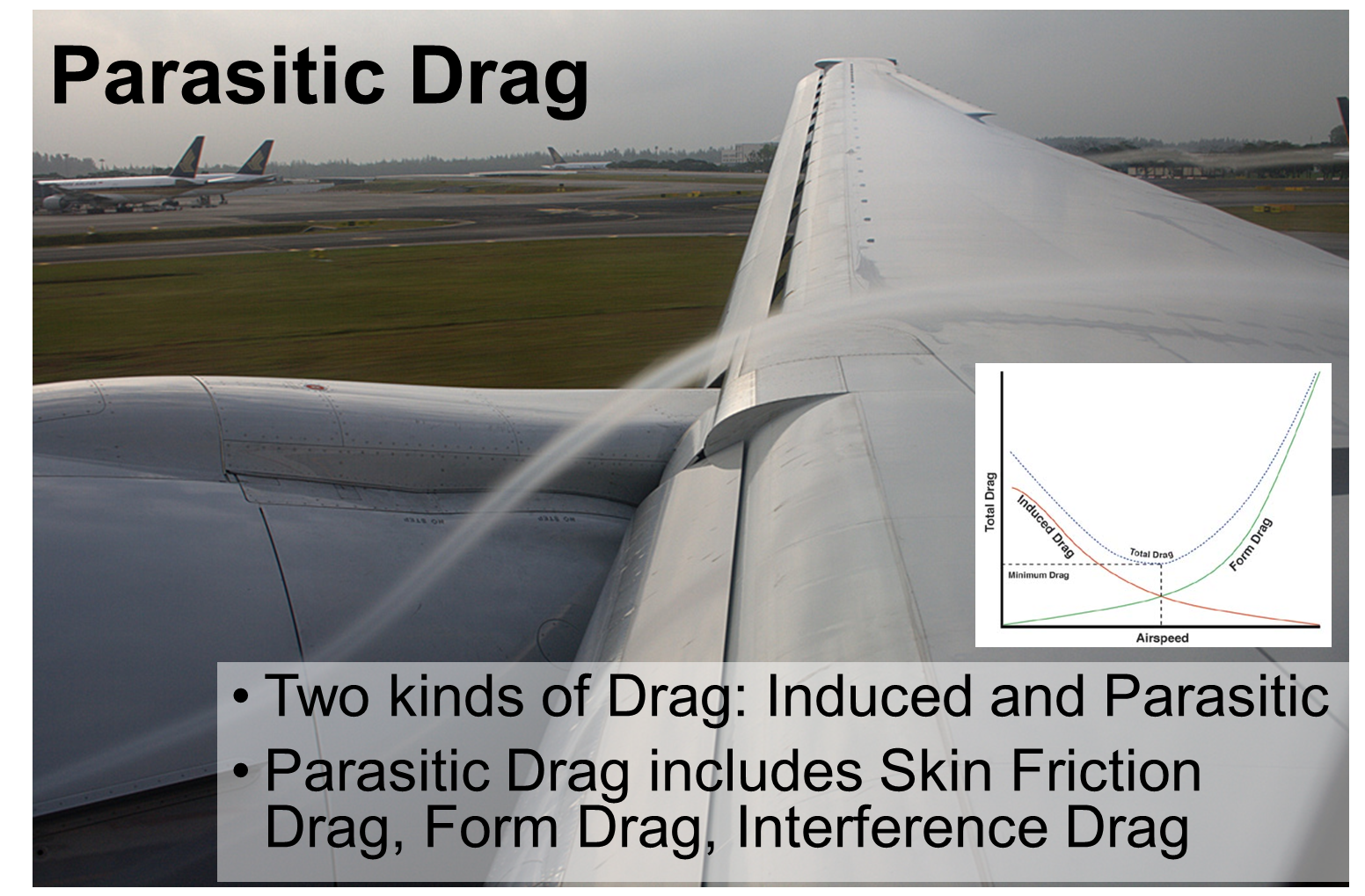

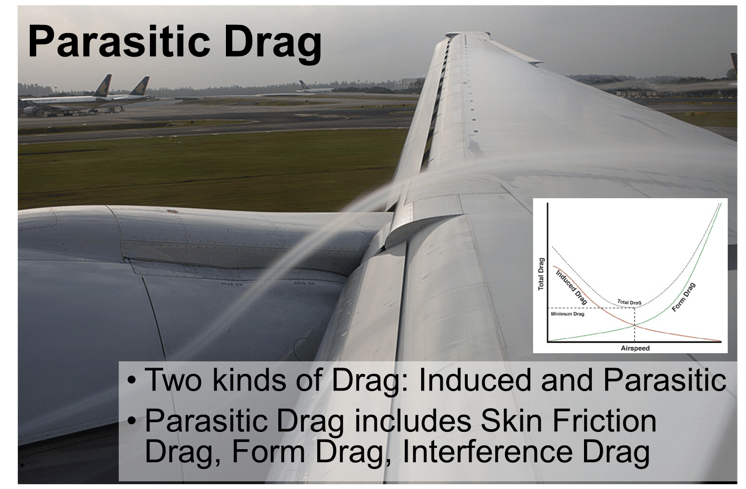

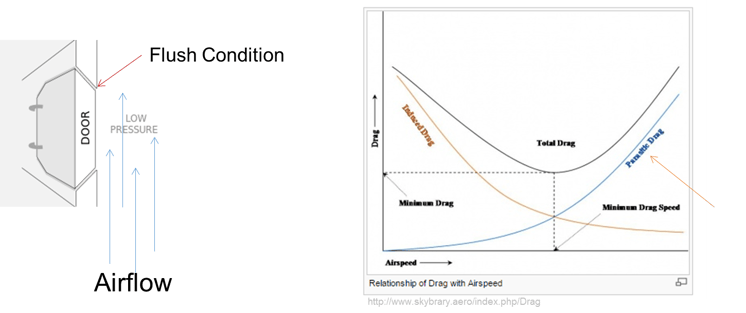

Variation can increase Parasitic Drag, thus increasing the amount of fuel spent to travel the same distance. Parasitic Drag, as opposed to Induced Drag, includes Skin Friction Drag, Form Drag and Interference Drag.

This blog focuses on just Skin Friction Drag, and how dimensional variation can affect it.

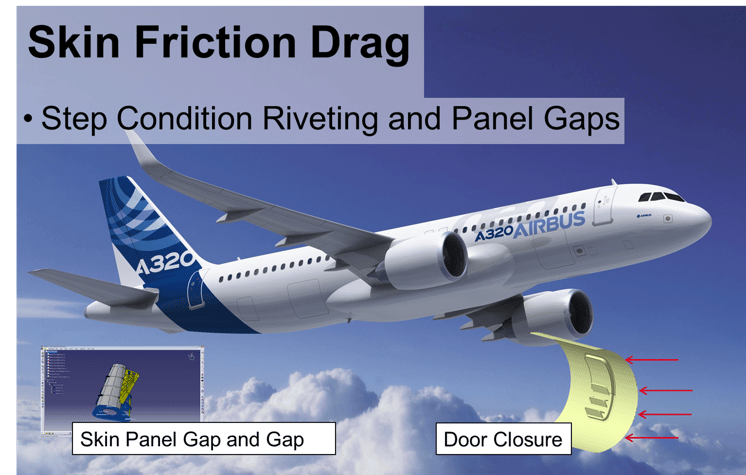

As noted, increasing drag increases the amount of fuel used over the life of the aircraft. This reduces the overall fuel efficiency of the plane. Different conditions, however, contribute to this value differently. A door's closure and overall flush condition will have a smaller impact than a large gap on an airfoil.

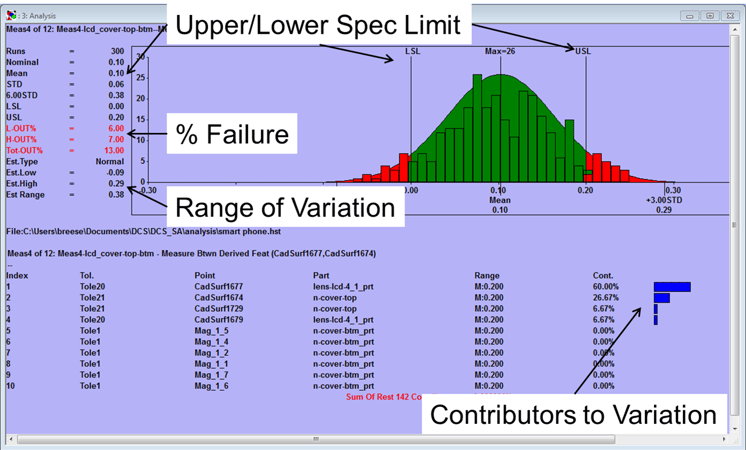

Using CATIA and 3DCS, the engineering team simulated variation on an airfoil and tailfin model. Applying Monte Carlo Analysis, builds within given design specifications were virtually created and assembled.

NOTE: Additional metrics (Pp, Cpk) were turned off for this study. For more information on 3DCS Analysis results, see http://www.3dcs.com/getting-started-3dcs-dimensional-analysis.html

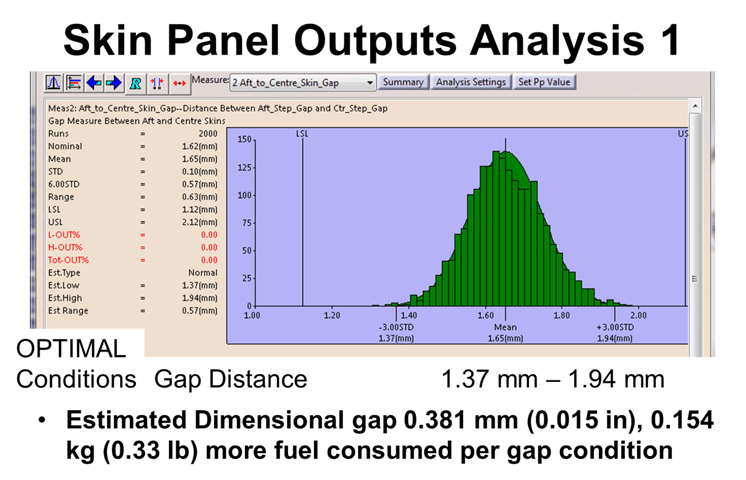

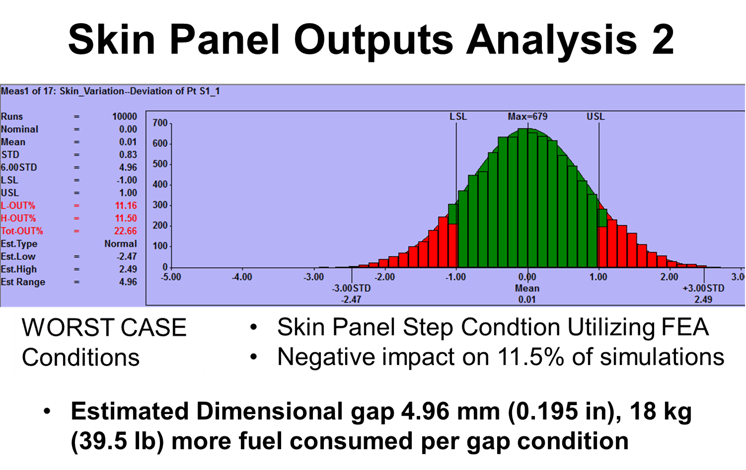

Two studies were completed to test the theory. Based on existing models, estimated effects of two condition sets were calculated.

These are based on a study of an Airbus A330 over 3000 miles, and are presented as examples of process, and not actual studies on the given product.

(Peeters, P. M.; Middel, J.; Hoolhorst, A. (2005). "Fuel efficiency of commercial aircraft: An overview of historical and future trends"(PDF). National Aerospace Laboratory. Retrieved July 6, 2014.)

3DCS Variation Analyst allows the user to input equations that can be used to determine indirect outputs from dimensional data. Fuel Efficiency is one example of an indirect output. With the aid of Aerospace Engineers and a complete study, this process can deliver more complete results.

It is often asked, how close are your simulations to reality?

This of course is based on how much effort went into the simulation. A basic simulation using rigid body moves can give quick results with relatively good accuracy (approx. 70%). In order to get more accurate results, more involved simulation is required, such as incorporating flexible parts and Finite Element Analysis.

Learn more about Finite Element Analysis and 3DCS by viewing the 3DCS Webinar: http://mkt.3dcs.com/compliant-modeler-finite-element-analysis-fea-webinar-on-demand-part-3

- Rigid body moves

- Quick Results

- Lower accuracy

- Compliant moves

- Longer analysis

- Higher accuracy

- Requires more technical expertise

Questions? Contact DCS to learn more

References:

These Stories on CATIA

No Comments Yet

Let us know what you think