This Thursday begins the fall 3DCS webinar series: 3DCS Version 7.8 Webinar Series. The series will cover 4 of the new features in the recently released new version and then end with a spotlight on the update 7.8.1.0.

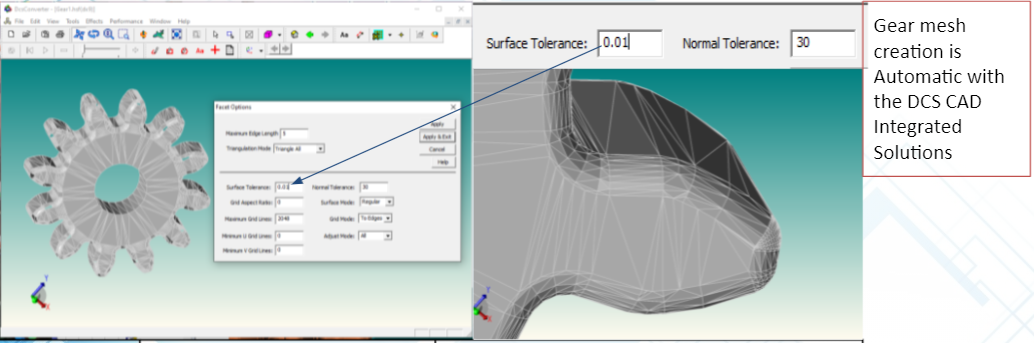

The first part of the 7.8 Webinar Series will showcase two new features; the Gear Module and Collision Detection. This will include an overview, with a link to watch a more in-depth video on how to use the new tools.

The Gear Module (part of 3DCS Mechanical Modeler Add-on Module), provides an easy-to-use tool for creating gear studies, tolerance stack-ups, and variation analysis models. The Gear Module creates the moves (assembly and kinematic motion) and the measurements (simulated inspection) on the 3D model for you, freeing you up to focus on your analysis and design requirements.

Understanding when your parts will run into each other or contact during assembly and use is important. Part collisions can cause additional wear and tear, as well as functional problems with many products. This new feature in the Mechanical Modeler Add-on for 3DCS Variation Analyst (all CAD platforms) gives you a clear understanding of when and where your parts will collide, providing you the ability to design out these issues or control the variation to acceptable levels.

The second part of the 7.8 Webinar Series will focus on the updates to the Worst-Case tools in 3DCS as well as the Pattern Move.

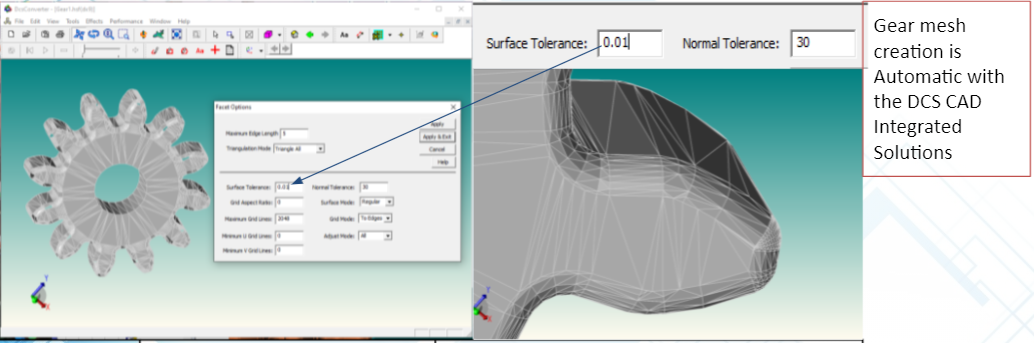

3DCS has been updated with more options for your worst-case analysis. These tolerance stack-ups set the values at their greatest values, showing the largest range of variation possible. Additionally, there are worst-case scenarios that cause the greatest amount of risk and product failure which may not be from setting all values to their largest amount.

Learn about the options within 3DCS to perform a Worst Case study including:

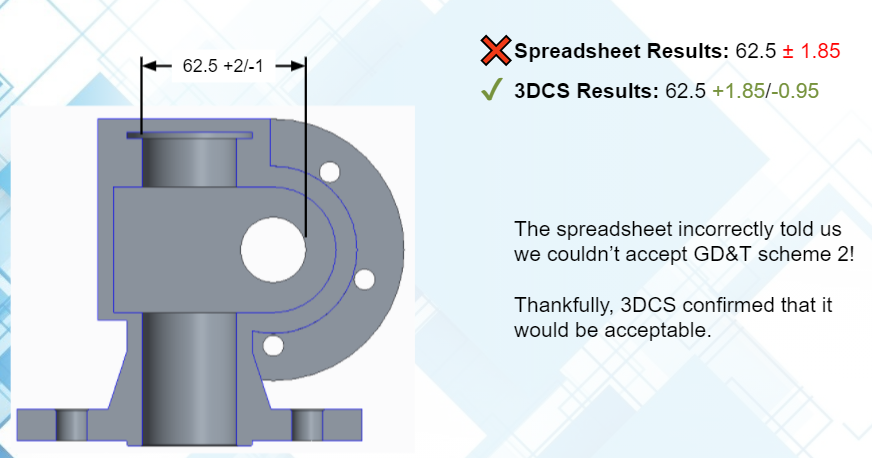

The Pattern Move is an important tool for any engineer using 3DCS. This assembly process allows you to simulate patterns of holes and pins, and see how they align and fit with your given tolerance specifications. This can help you understand whether parts will fit in assembly, or require adjustments to specific holes, or changes to slots in order to assemble correctly without the need to enlarge holes or alter the parts.

New features in the Rigid Pattern move include the ability to float slots onto pins and tabs. This is what is covered in this presentation:

The list of items to make it into 3DCS Version 7.8 was monumental. Not everything made it into the initial release. 3DCS Version 7.8.1.0 Update adds additional GD&T tools and updates the best fit routines and X-Plane moves. Join the webinar to see the updates yourself and learn how to apply these tools in your models.

These Stories on CATIA

No Comments Yet

Let us know what you think