This is a sample - for the complete article go to: https://www.manufacturingsolutions.sandvik/en/news-stories/lpblog/2024/04/7-key-concepts-for-dimensional-engineering

Dive deeper to understand the line between satisfactory and unsatisfactory for component designing?

I often define dimensional engineering as the study of how part level imperfections affect a product at the assembly level. We all understand that our parts will be somewhat imperfect when they are manufactured (nothing is perfect), but how much imperfection can our design absorb and still be considered satisfactory? To answer this question and describe the Dimensional Engineering process we’ll cover 7 key concepts.

A dimensional requirement is a specific necessity of the end product that must be measured and fall within a certain range. It answers the question “what is the line between satisfactory and unsatisfactory for our design?” It could be something aesthetic such as the gap/flush between two pieces of bodywork on a car. It could also be something functional such as ensuring the charging port on a phone lines up with a hole in the housing. In a perfect world, a gap designed to be 6mm will always be 6mm; in reality this won’t be the case. Accompanying any dimensional requirement will also be a range of acceptable values for that dimension after assembly.

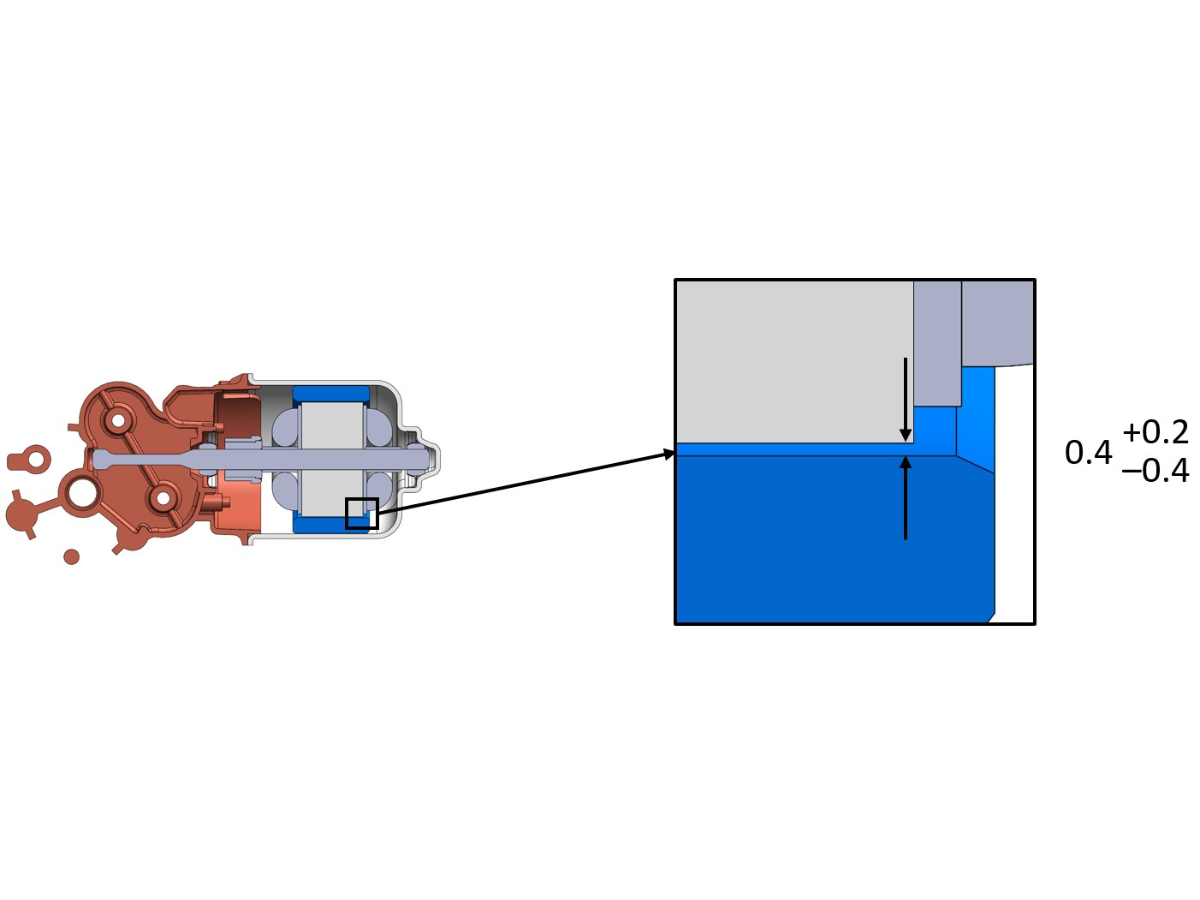

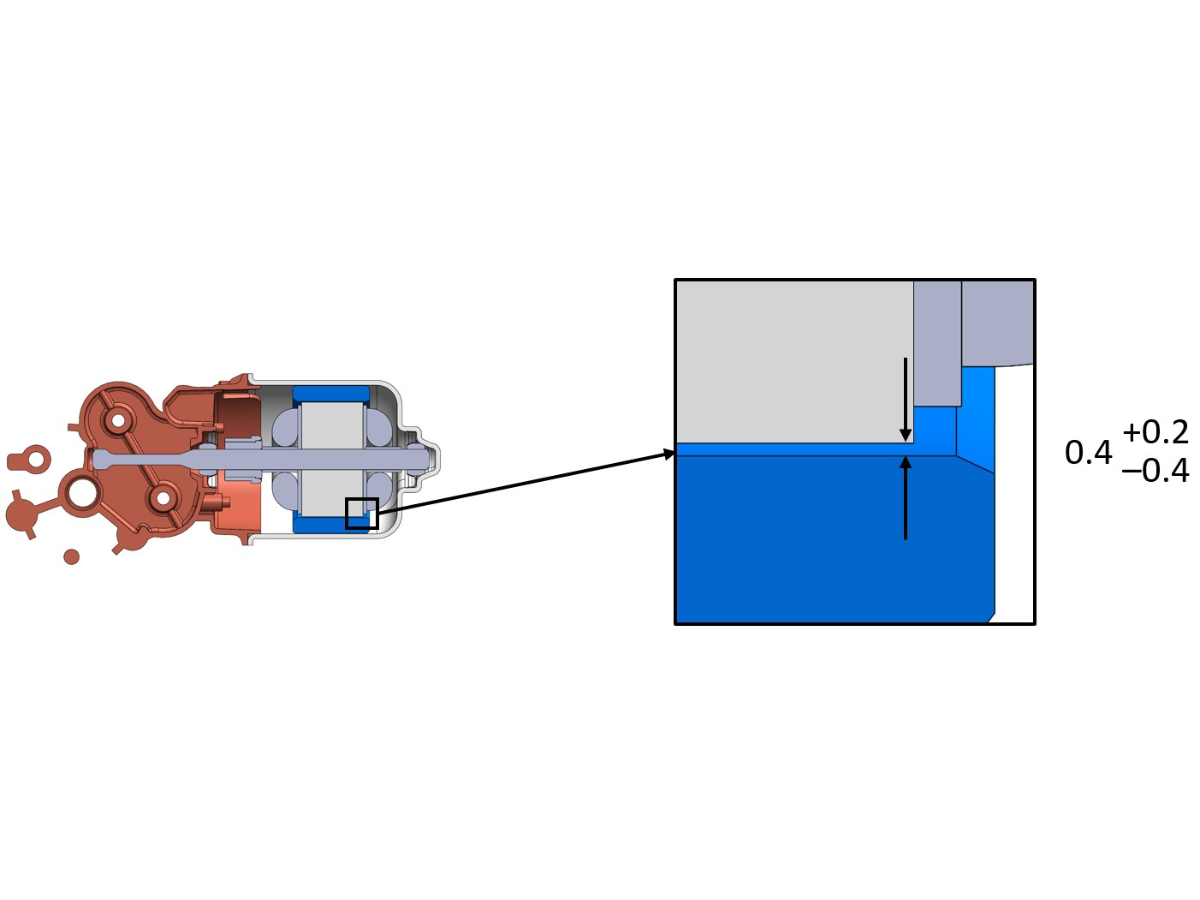

In the example below, the gap between the motor (grey part) and the stator (blue part) is designed to be 0.4mm, but the product will be considered satisfactory if the gap falls between 0mm and 0.6mm: The limits of the requirement in this case are functional: if the gap decreases to less than 0mm then we will have scraping between the motor and the stator and if the gap increases to greater than 0.6mm then we have a performance problem, the motor is too far from the stator for ideal motor performance.

The limits of the requirement in this case are functional: if the gap decreases to less than 0mm then we will have scraping between the motor and the stator and if the gap increases to greater than 0.6mm then we have a performance problem, the motor is too far from the stator for ideal motor performance.

These Stories on CATIA

No Comments Yet

Let us know what you think