Organized by SME - the Society of Manufacturing Engineers - the MFG4 conference began each day with a keynote. The first was presented by GE Global Chief Manufacturing Scientist Stephan Biller -

Keynote Presentation: The 21st Century Brilliant Factory

Stephan Biller, Chief Manufacturing Scientist, Manufacturing and Research

GE Global Research

I was very excited to hear Stephan Biller speak, and took away some great points. Some of the ideas that I took away from the keynote included the drive for Data Driven Manufacturing, America's Educational Shortcomings and the increasing Interconnection of Systems.

(Connecticut Conference Center images courtesy http://www.ctconventions.com/)

The concept of data driven manufacturing is not new, but the ability to truly achieve it is.

Metrology systems are more accurate now than they have ever been. It has been remarked to me that metrology has now surpassed manufacturing in its ability to measure to a much greater detail than manufacturers can produce. I would think that more accurate to state, "than manufacturers can produce affordably."

Regardless of produce-ability, as that is a separate topic altogehter, the concept of using measurement and inspection data to drive manufacturing improvement is an important one. Measurement devices are becoming cheaper and more portable, making the idea of easy inline inspection, accurate vision based scanning and quick CMM probing a reality. With so much measurement possible, there comes a true quandary, what to do with all the data?

Saying that you are going to use data to drive lean manufacturing and continuous improvement is an easy remark. Implementing it successfully is very different altogether. If it weren't so, there would not be such a need for Six Sigma Black Belts and quality professionals. Implementing advanced measurement systems now requires a system to aggregate the data and make it usable, that is, mine it for real intelligence. Raw data can quickly drown a quality or plant manager, as the sheer ability to generate it is staggering, but the ability to turn into something readily usable for making decisions and changing process to reduce non-conformance and scrap is much harder to deliver.

Saying that you are going to use data to drive lean manufacturing and continuous improvement is an easy remark. Implementing it successfully is very different altogether. If it weren't so, there would not be such a need for Six Sigma Black Belts and quality professionals. Implementing advanced measurement systems now requires a system to aggregate the data and make it usable, that is, mine it for real intelligence. Raw data can quickly drown a quality or plant manager, as the sheer ability to generate it is staggering, but the ability to turn into something readily usable for making decisions and changing process to reduce non-conformance and scrap is much harder to deliver.

This is nothing new to anyone who works in manufacturing. Skills that used to be more commonplace are now difficult to find. Trade schools are much rarer now, and most universities stress the social sciences, medicine and advanced engineering degrees. This isn't to say that those fields are not needed, but so too are welders, machinists and stampers. In addtion to these fields, there is still a lack of engineers to develop tomorrow's products.

Here is a snap shot of engineering from 2011-2012 that highlights the engineering field in universities. It shows that there is still a large amount of engineers graduating, but the rising demand for experienced engineers is still not being met.

DCS has a small staffing team that helps customers find specialty roles for projects. Begun as a means of helping customers with 3DCS projects, the team now helps fill all manner of engineering roles. As the marketing manager at DCS, I have had the pleasure of working with them at a number of events and job fairs to meet potential candidates. One thing I've heard from all recruiters is the demand for engineers is becoming greater and greater, but there seem to be fewer and fewer. Moreso, there is a great need for engineers with industry experience, of which there is a shrinking number.

So how do you increase the number of engineers in the USA? That's a difficult question to answer, and one I am grossly underqualified to tackle. Here is Charles Vest, National Academy of Engineering, discussing the topic.

Many processes and systems within a plant are disjointed. They do not communicate to one another, and do not all communicate to a single source. A plant of the future will have all processes and machines communicating through a central source, allowing information to be used throughout the process, and aiding in quality control.

In the modern day, we have MES, ERP, QMS and even more acronyms for software systems to connect plant processes. There is no single solution, because there is not a standard for which all plants fit. Some are larger, more complex than others, while a highly complex, expensive system would be too much for a smaller plant with basic widgets (nuts, bolts or plastic switches) to afford. Therefore, it is usually a hybrid of these systems that comes together to solve the issues at a plant.

In DCS's experience, manufacturers are not one group to discuss, but a very diverse group of companies, professionals and processes. Each of these in turn has different needs and different resources available to meet those needs. At DCS, we provide a QMS system for addressing measurement data and inspection data analysis, giving answers to quality control questions and driving lean manufacturing processes. This is just one piece of the puzzle, though, and is not the answer to all the needs a plant has. Logistics and accounting, compliance documentation, raw material inventory, staffing and labour, machine quality and maintenance all require their own information systems. Whether tha system is a clip board or advanced software platform depends very much on the plant, the needs and resources available.

The second keynote touches on a topic we have seen all over the news: Additive Manufacturing.

Keynote Presentation: Additive Manufacturing/3D Printing for Orthopaedic Devices

Gene Kulesha, Senior Director, Platform Technology Engineering, Research and Development Business Unit, Reconstructive Division

Stryker Orthopaedics

Stories about how 3D Printing and Additive Manufacturing have already changed the surgical world abound.

Tiny Printed Heart Makes Infant Surgery Possible

Tiny Printed Heart Makes Infant Surgery Possible

Additive Manufacturing Builds a New Heart

3D Printing: NYC Hospital Uses Printer to Build 3D Heart for Baby With Congenital Heart Defect

The ability to create replicas of organs and test surgical processes before opening up a patient has vastly improved many dangerous surgeries. A stint used to be formed and fitted while a patient was open on the table, while now with additive manufacturing, a copy of the patients heart can be made and stint pre-fitted before surgery begins. Stories like this show us how additive manufacturing will affect the medical world, but how will it affect traditional manufacturing?

(Image courtesy http://www.waykenrm.com/)

At DCS, we are watching as Additive Manufacturing, which has in essence been around for almost 30 years, becomes more economical. The ability to produce hundreds of products at one time, and to create very inexpensive plastic components with incredible amounts of detail, without having to develop molds, stamping dies or tool machines, will make custom development and manufacturing possible in a way never seen before. This may cause new, unforseen dimensional issues, as the speed at which new parts can be designed and made without knowledge of how the design will affect the larger assembly, can cause unforeseen issues. DCS is waiting to see if 3DCS will be the answer to this problem, with the ability to quickly update models with new parts from CAD, and re-run complex dimensional studies to determine the geometric impact of design and process changes.

In addition to the keynotes, there were a number of breakout sessions, workshops and presentations. New, advanced CMM's, hand scanners and complex robitics were on display, complemented by software systems to run any and all processes of a manufacturer or business environment.

MFG4 was great event put on by SME - where software, machine and manufacturing professionals were able to collaborate on the changes and new innovations in the industries of aerospace, medical and defense.

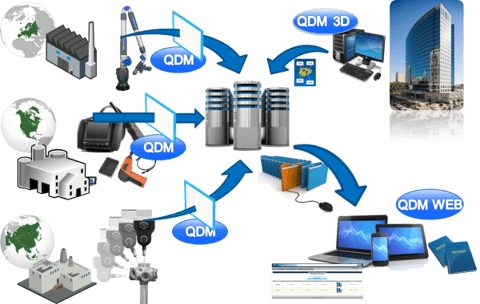

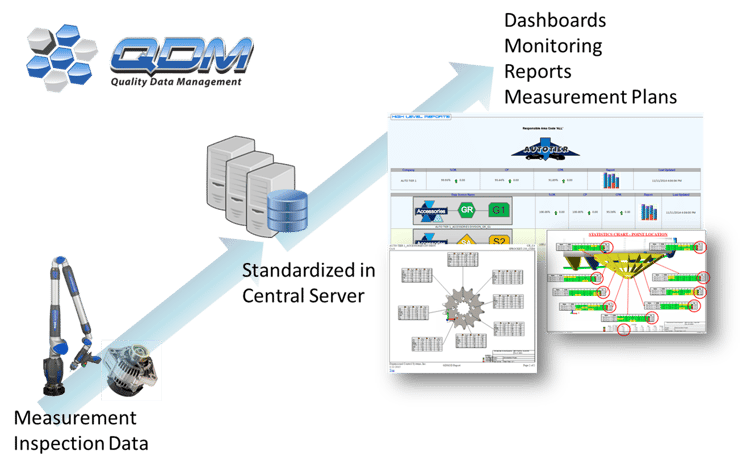

As mentioned above, one of the key pains experienced by manufacturers is the struggle to use the data they are collecting. This requires centralization of data, standardization of it and easy mining of that data for information to answer questions about quality, process and capability. DCS seeks to address these issues with application of QDM systems.

QDM answers this need by utilizing a central server, and the abiltiy to automate the collection of data to bring it together into the central database. QDM converts the data, making it easier to store, and then use for both QDM and for downstream applications like Matlab and Minitab.

Measurement devices do not offer a standard format. Some programs can output the same format in the sense of .CSV or .TXT files, but the data is arranged, displayed and provided differently. This makes comparing data sets, and seeing important trends difficult. QDM comes with translators for most measurement devices, with easy to configure new translators, to convert all of the data files into a single format on the database. This lets quality professionals see apples to apples data instead of having to piece the different data views together and reformat the results.

Bringing data together and standardizing it is only half the story. What quality professionals and plant managers need is real insight into their process and part quality. This means mining the data into real actionable information. QDM automates this process, providing dashboards and real-time monitoring to see minute by minute the quality of the parts produced, and reports for collaborating and drilling down into the data. Rather than a simple go/no-go system, QDM allows users to dive down into the data, and get answers to why their parts are not meeting specifications, and where that problem is occuring in production. This can save a lot of time normally spent hunting down the issue or worse yet, shutting down the line.

Learn more about DCS's manufacturing solutions at http://www.3dcs.com/software.html

These Stories on QDM

No Comments Yet

Let us know what you think