Hartford, CT - Dimensional Control Systems (DCS) is showcasing the new product 3DCS for NX at the Manufacturing 4 the Future Conference (Mfg4) in Hartford Connecticut USA May 3rd through the 5th. Exhibiting at booth 1317, DCS will be highlighting the benefits of using an integrated tolerance analysis tool within NX that leverages Teamcenter and the modules of NX.

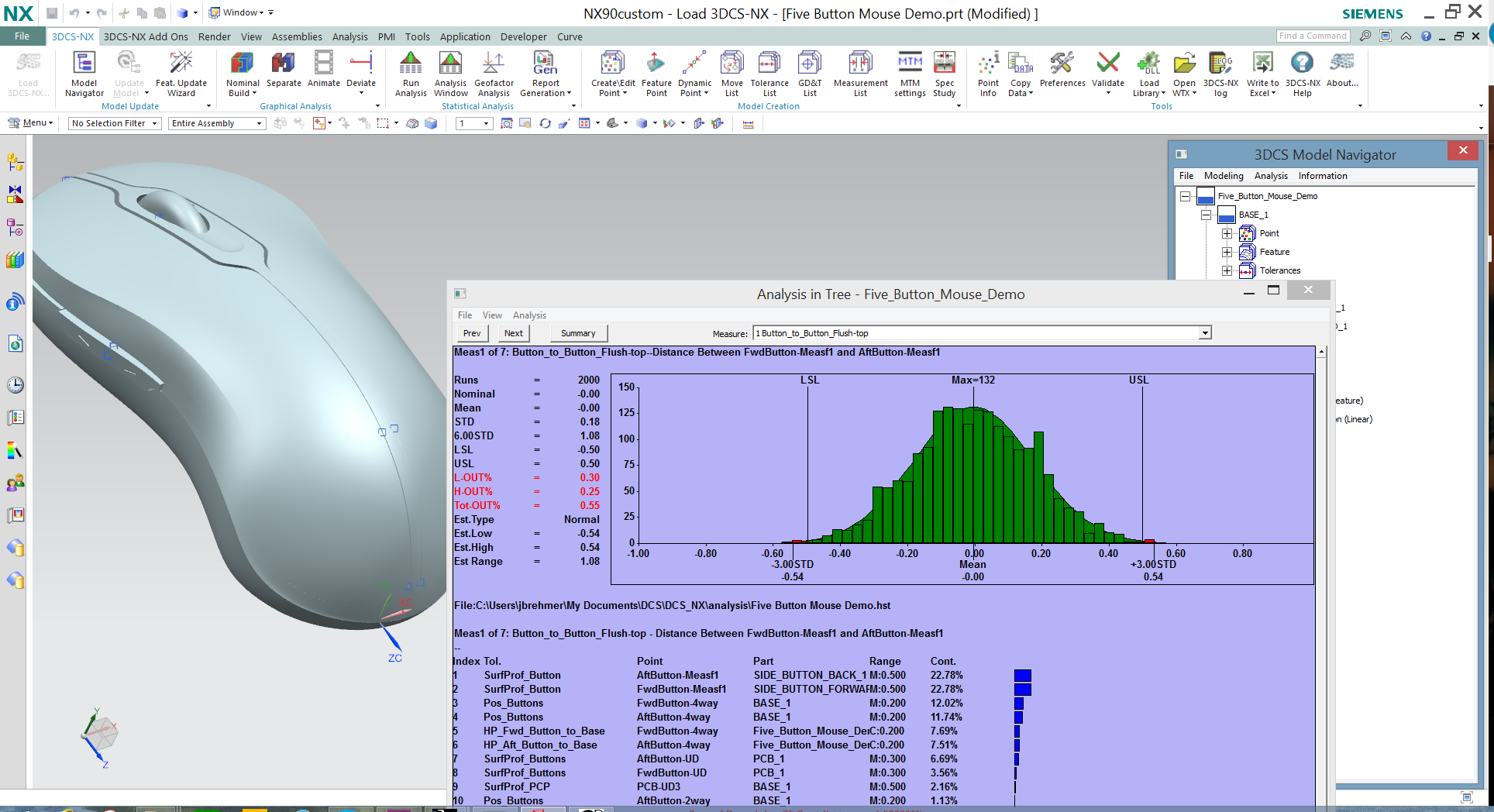

3DCS Variation Analyst for NX (3DCS for NX) is fully integrated in Siemens NX. This allows users to work within a single environment, adding variation analysis and GD&T optimization to their modeling without having to export or import models or incorporate outside tools. This seamless workflow reduces the need for training, increases productivity and takes advantage of the NX investment as well as promoting consistency in GD&T and process.

As part of DCS's Closed Loop process, 3DCS for NX gives users the ability to pull data from Teamcenter or to apply tolerance analysis directly onto NX math models without having to export or change environments. By utilizing the Siemens NX platform, 3DCS is able to store models directly in Teamcenter, controlling revisions and promoting easier collaboration with peers.

1. Teamcenter Utilization- Save your models and control revisions within your PLM system

2. PMI- Take advantage of your GD&T and PMI (Product and Manufacturing Information) to streamline the modeling process and to optimize your GD&T for best quality at lowest cost

3. Update Geometry- Is the design team still making changes to the product? Incorporate new parts and design changes quickly into your model, without having to import/export models or worry about translation issues.

4. Visualization - NX offers both Advanced Visualization and Ray Traced Studio to quickly add high end visualization to your models. Use Advanced for quick checks and Spec Studies, then apply Ray Traced Studio and environments to see life like depictions of your products that include part and process variation.

"Mfg4 brings together professionals from a multitude of industries; aerospace, defense, medical device manufacturers and more as an opportunity to share and learn about the latest trends in manufacturing technology and process improvement," said Michael Pritchard, DCS Account Executive. "This is the perfect opportunity to network and connect with leaders in these industries to learn best practices as well as share the accomplishments major manufacturers have achieved by applying dimensional engineering and 3DCS tools."

Join DCS at booth 1317 to learn more about how OEM's across the globe are applying 3DCS to reduce scrap, rework and warranty/liability claims.

Click here to learn more about 3DCS for NX

These Stories on 3DCS

No Comments Yet

Let us know what you think